What is a Hyperspectral Camera? A Game-Changer in the Recycling Industry

9 Apr 2025

As sustainability becomes a global priority, the recycling industry is evolving to meet growing demands for precision and efficiency. Among the technologies leading this transformation is the hyperspectral camera—a sophisticated tool that enables more accurate sorting of materials based on their chemical composition.

In this article, we’ll explore what a hyperspectral camera is, how it works, and why it’s revolutionizing recycling operations worldwide.

What is a Hyperspectral Camera?

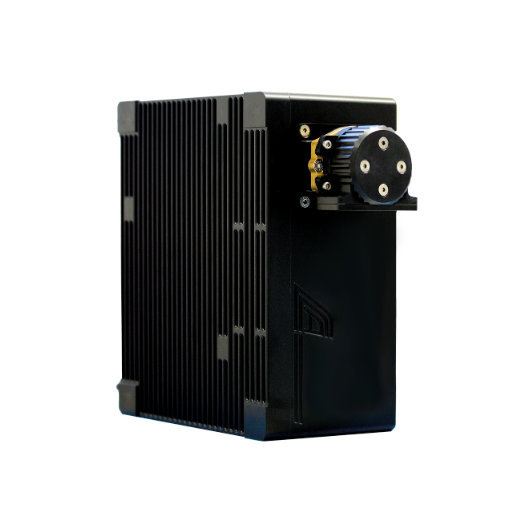

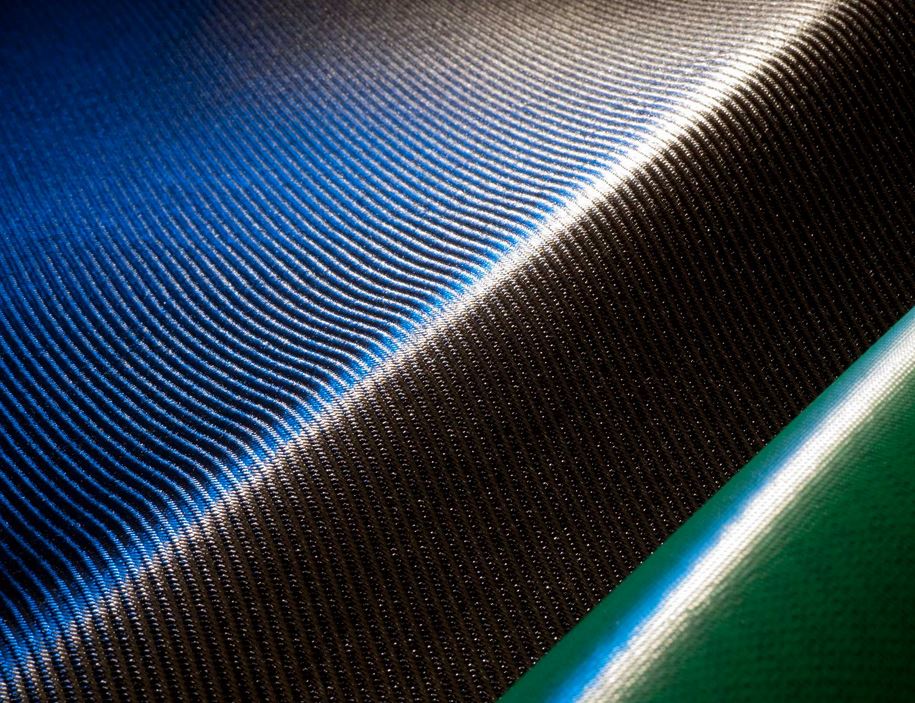

A hyperspectral camera captures images across a wide spectrum of light beyond what the human eye can perceive. Unlike traditional RGB cameras that only detect red, green, and blue wavelengths, hyperspectral imaging systems collect data from hundreds of narrow spectral bands. This allows them to identify materials based on their unique spectral fingerprints.

In practical terms, hyperspectral cameras can detect subtle differences in material properties—such as polymer type, moisture content, or contamination level—which is especially valuable in industrial applications like automated recycling.

Why Hyperspectral Imaging Matters in Recycling

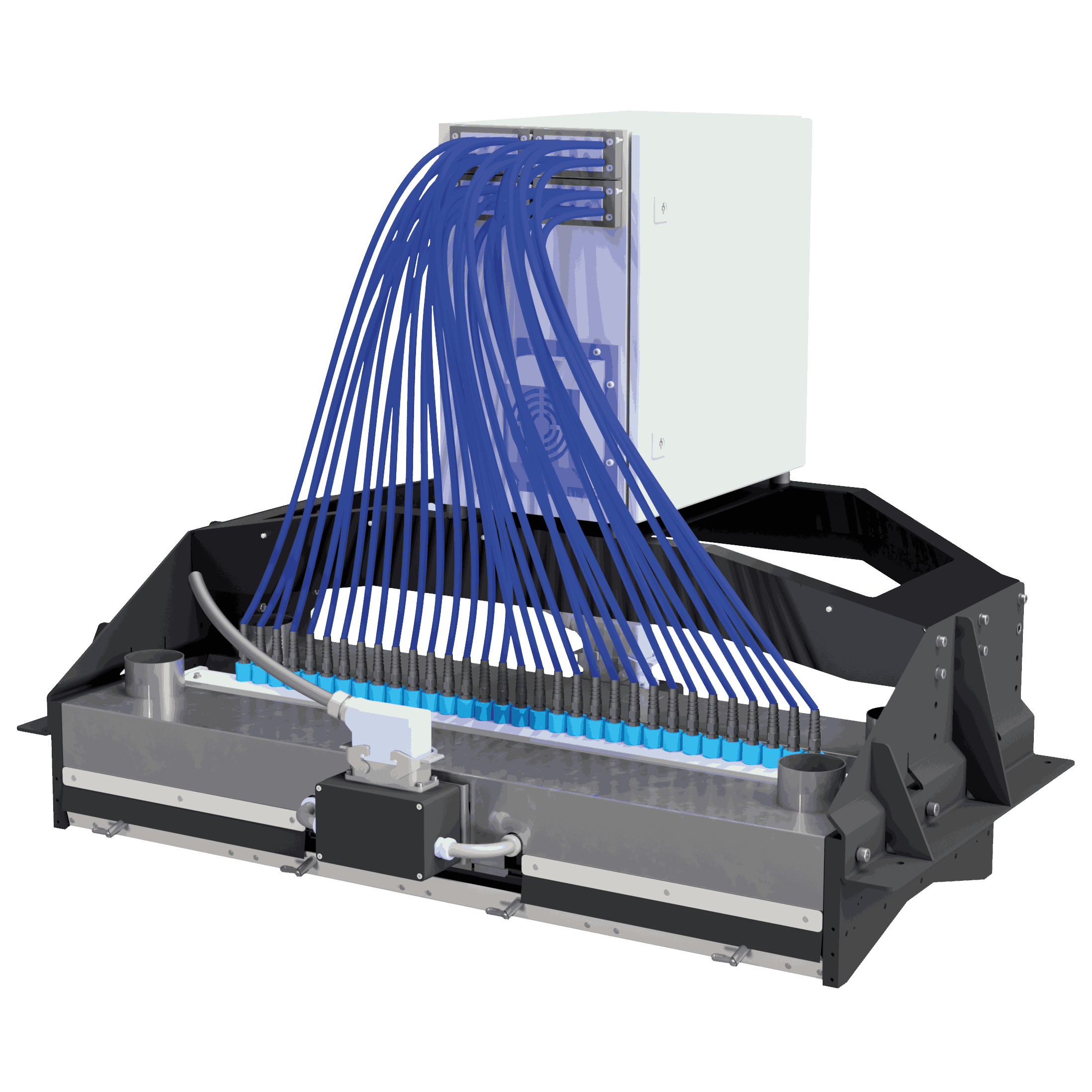

Precision Sorting for Higher Purity

In modern waste management and recycling plants, achieving high purity levels in sorted materials is critical. Manual or conventional optical sorting methods often struggle to distinguish between visually similar plastics or to detect black plastics, which can absorb visible light.

Hyperspectral cameras overcome these limitations by analyzing the infrared spectrum to differentiate materials at a molecular level.

This leads to:

- Improved recovery of valuable resources

- Reduced contamination in output streams

- Increased throughput with consistent accuracy

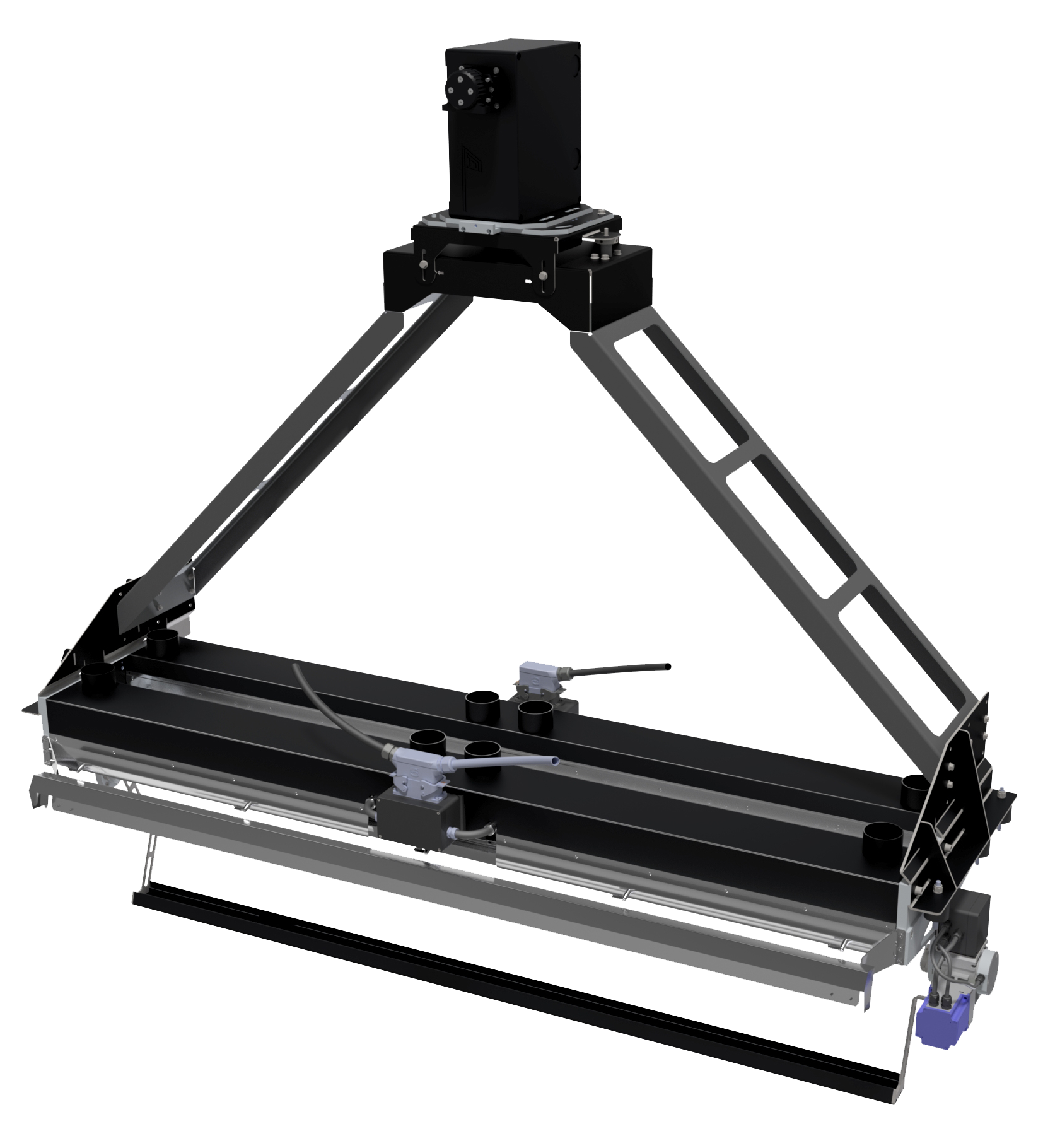

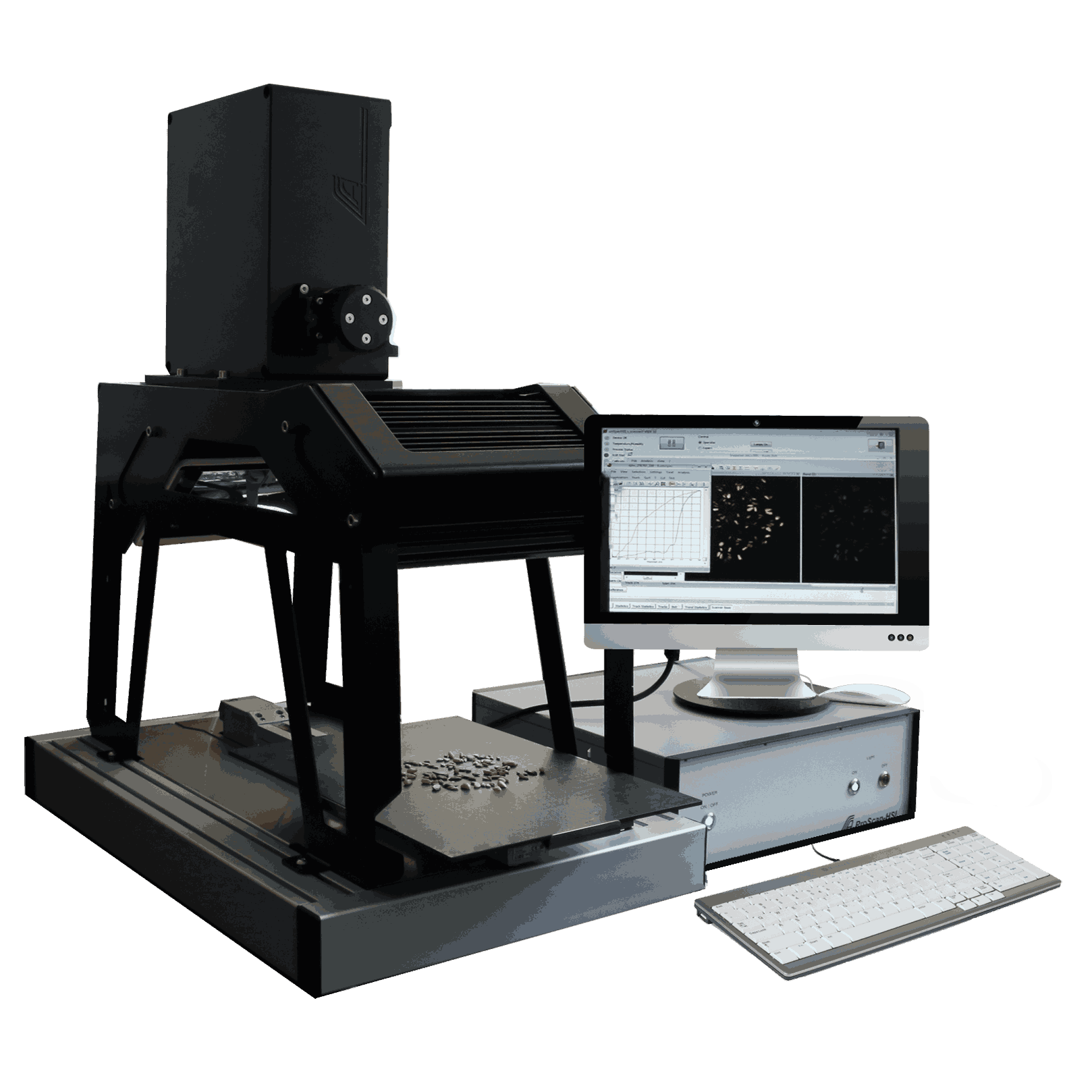

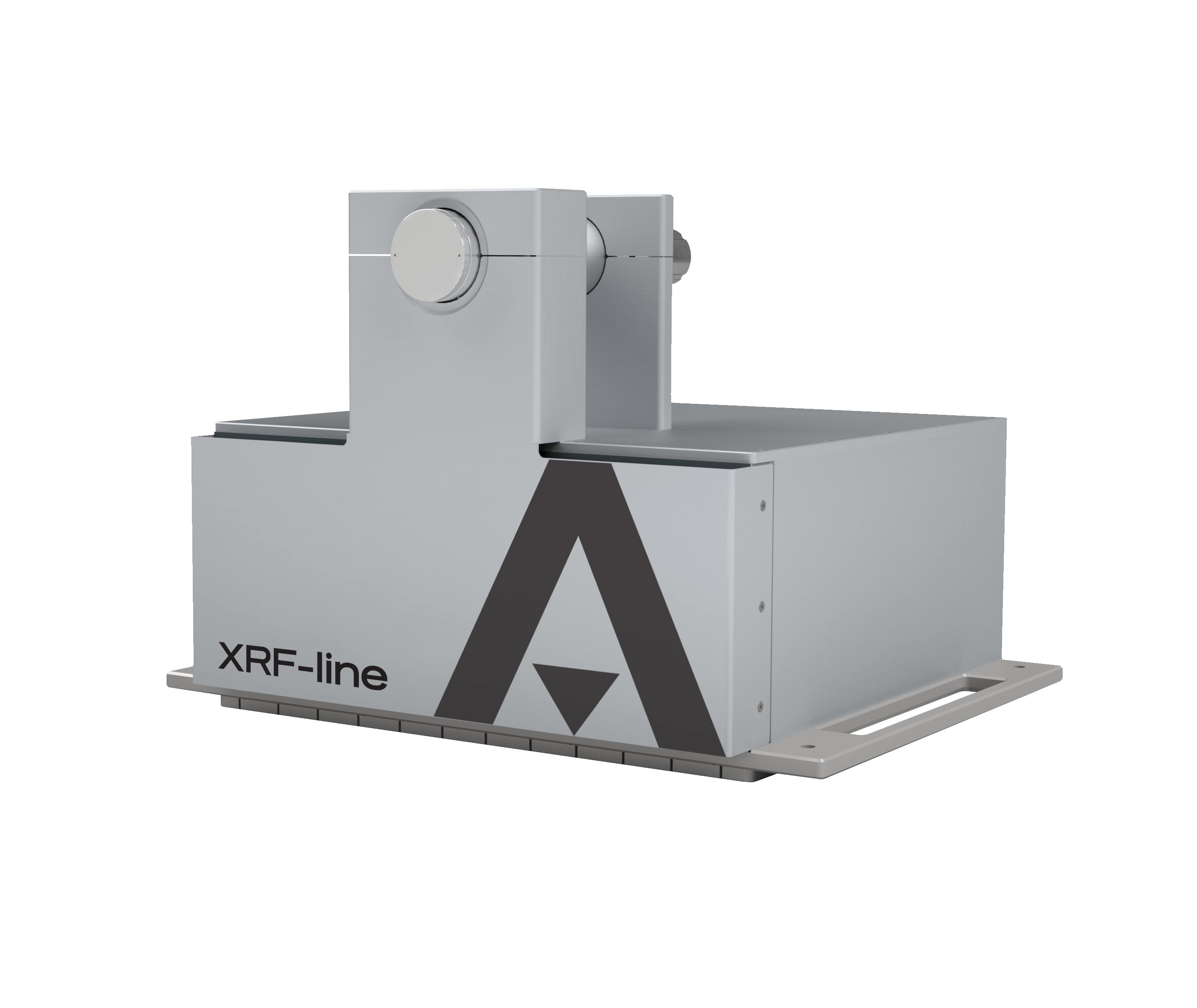

For example, LLA Instruments offers state-of-the-art hyperspectral camera systems specifically engineered for sorting plastics, metals, glass, and minerals—making them indispensable in circular economy strategies.

How Does a Hyperspectral Camera Work?

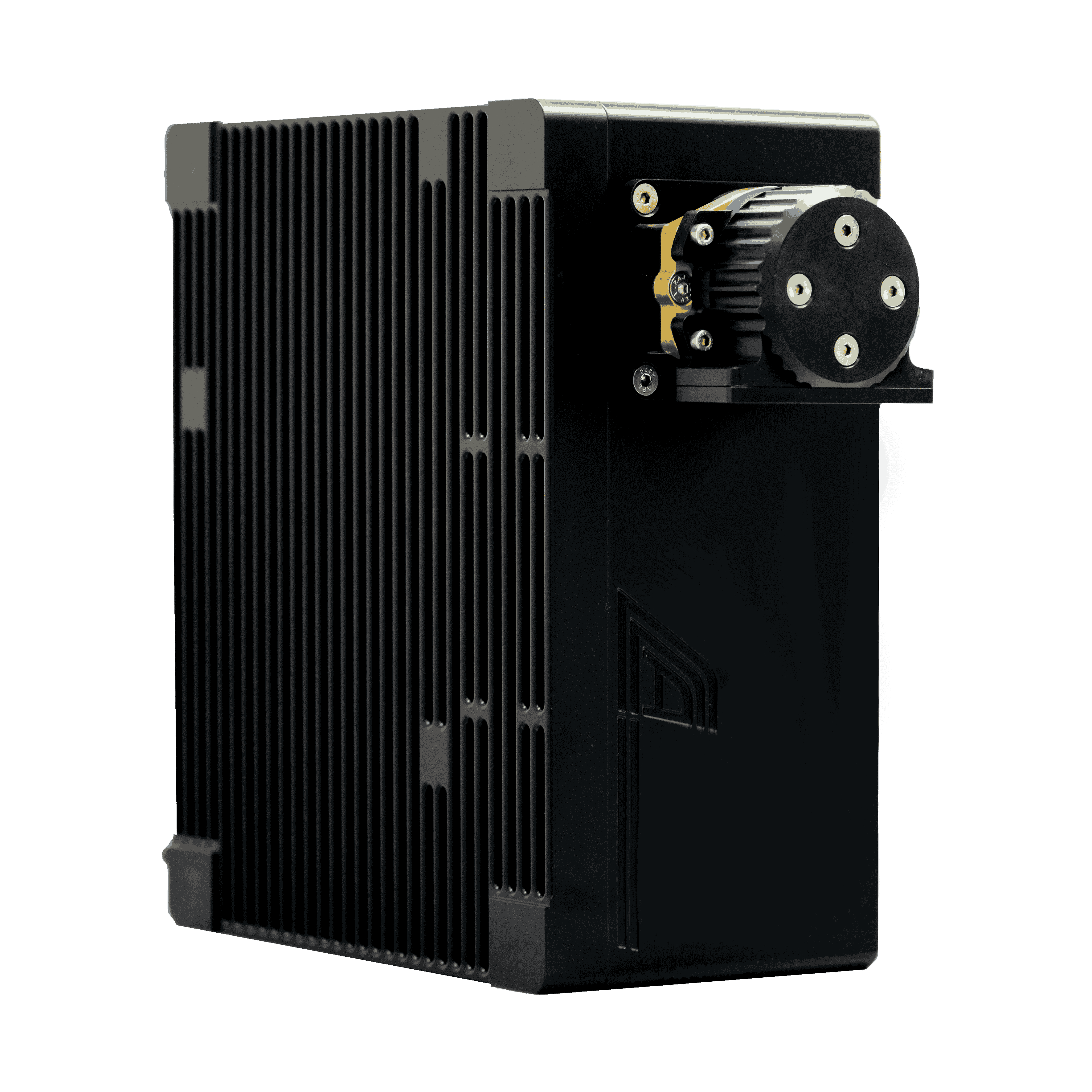

At the core of hyperspectral imaging is a spectrograph that splits incoming light into hundreds of spectral bands. The camera then records this spectral information for every pixel in the image, generating a detailed 3D data cube (two spatial dimensions + one spectral dimension).

This data is processed using powerful algorithms and machine learning models to classify materials with high precision. In the recycling industry, this enables real-time decisions on sorting belts, often in milliseconds.

Common Spectral Ranges Used:

- VNIR (Visible and Near Infrared): ~400–1000 nm

- SWIR (Short Wave Infrared): ~1000–2500 nm

These ranges allow identification of a wide array of materials, even in complex waste streams.

Applications in the Recycling Industry

Hyperspectral cameras are currently transforming several key sectors within recycling:

1. Plastic Sorting

Different polymers (PET, HDPE, PVC, etc.) have distinct spectral signatures. Hyperspectral imaging ensures accurate separation, even for black plastics, which are traditionally challenging to sort.

2. Metal and Mineral Detection

These cameras detect coated metals, composites, and non-ferrous metals, improving resource recovery and reducing landfill waste.

3. Organic and Food Waste Separation

In bio-waste processing, hyperspectral sensors can distinguish between biodegradable and non-biodegradable contaminants, supporting clean compost production.

For more industry-specific solutions, check out LLA Instruments’ product page for recycling systems.

Trust in Proven Technology

Companies like LLA Instruments GmbH have decades of experience in developing hyperspectral imaging technologies tailored for industrial use. Their systems are widely adopted across Europe and internationally due to their reliability, performance, and compliance with quality standards.

Incorporating a hyperspectral camera into your recycling workflow signals not just technological innovation, but also a commitment to environmental responsibility and resource efficiency.

Final Thoughts

The future of recycling is smart, and hyperspectral imaging is at its forefront. As regulatory demands increase and raw materials become scarcer, investing in advanced sorting technologies like hyperspectral cameras is no longer optional—it’s essential.

Ready to bring hyperspectral technology to your recycling operation?

Explore LLA Instruments’ hyperspectral camera solutions and speak to an expert about how to enhance your material sorting accuracy and operational efficiency.

Previous Post

Previous Post