Home / Products / XRF-line

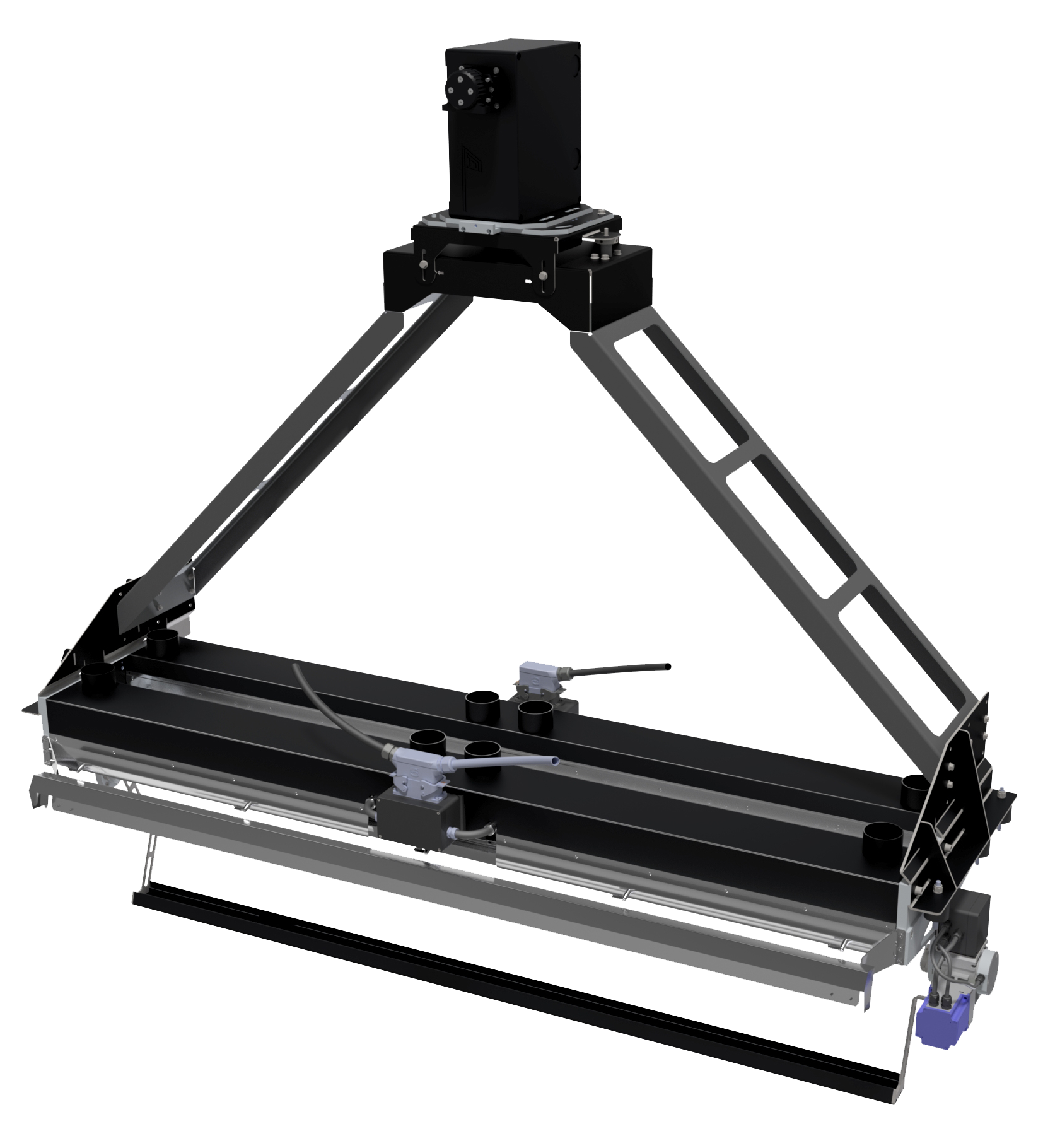

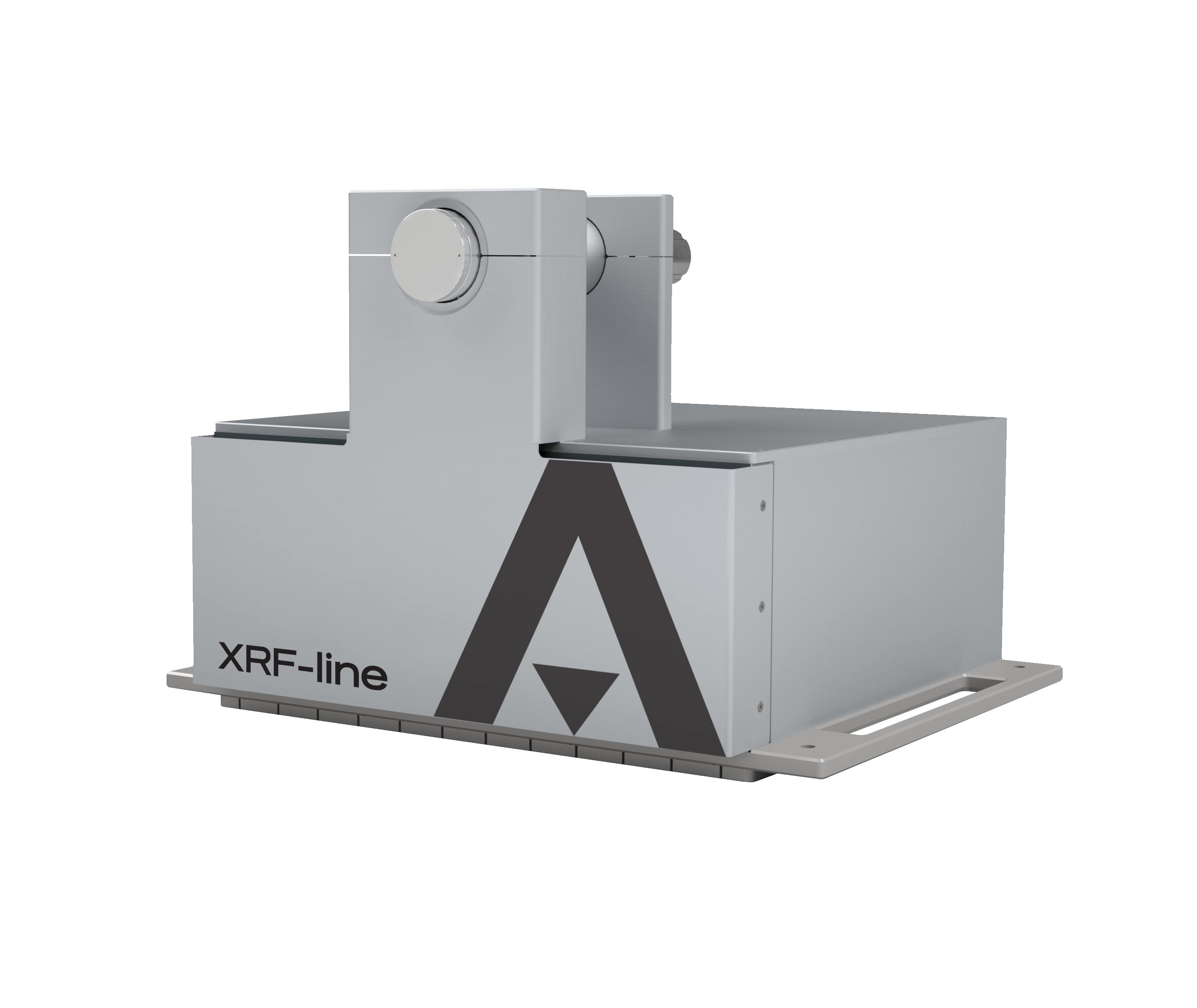

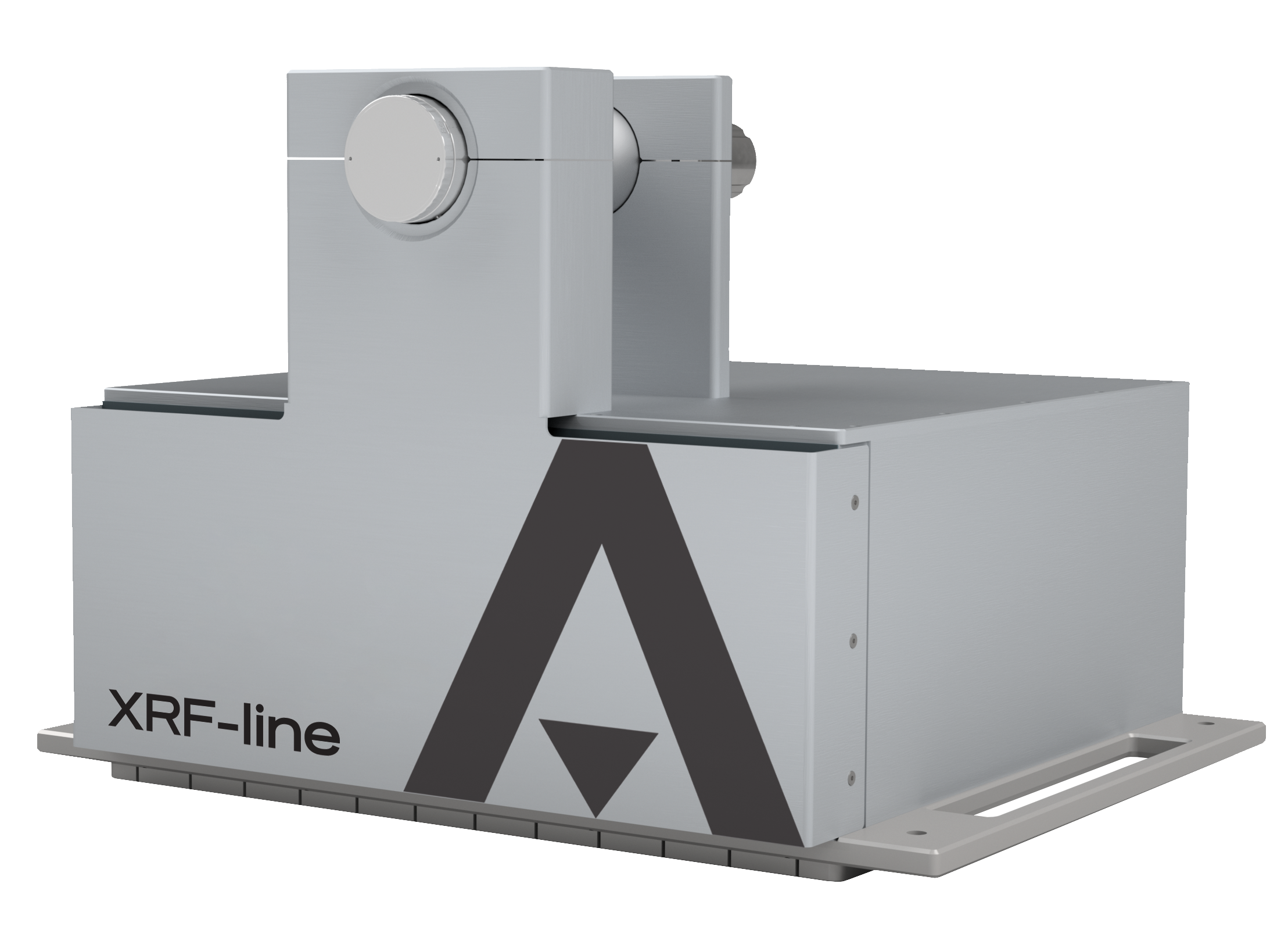

XRF-line

X-ray fluorescence analyser for metal sorting & materials analysis

XRF-line

High-Performance XRF Metal Sorting and Material Analysis System

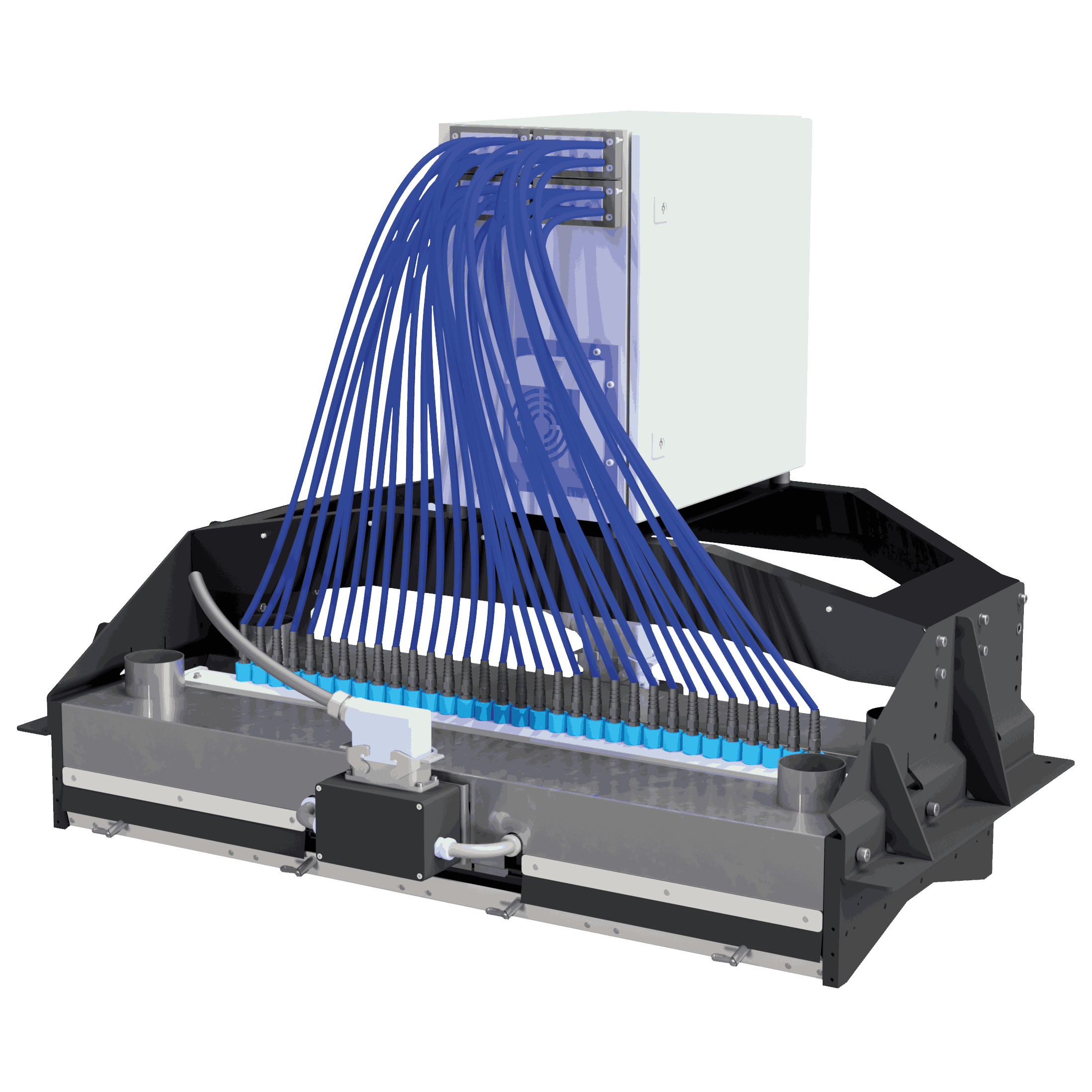

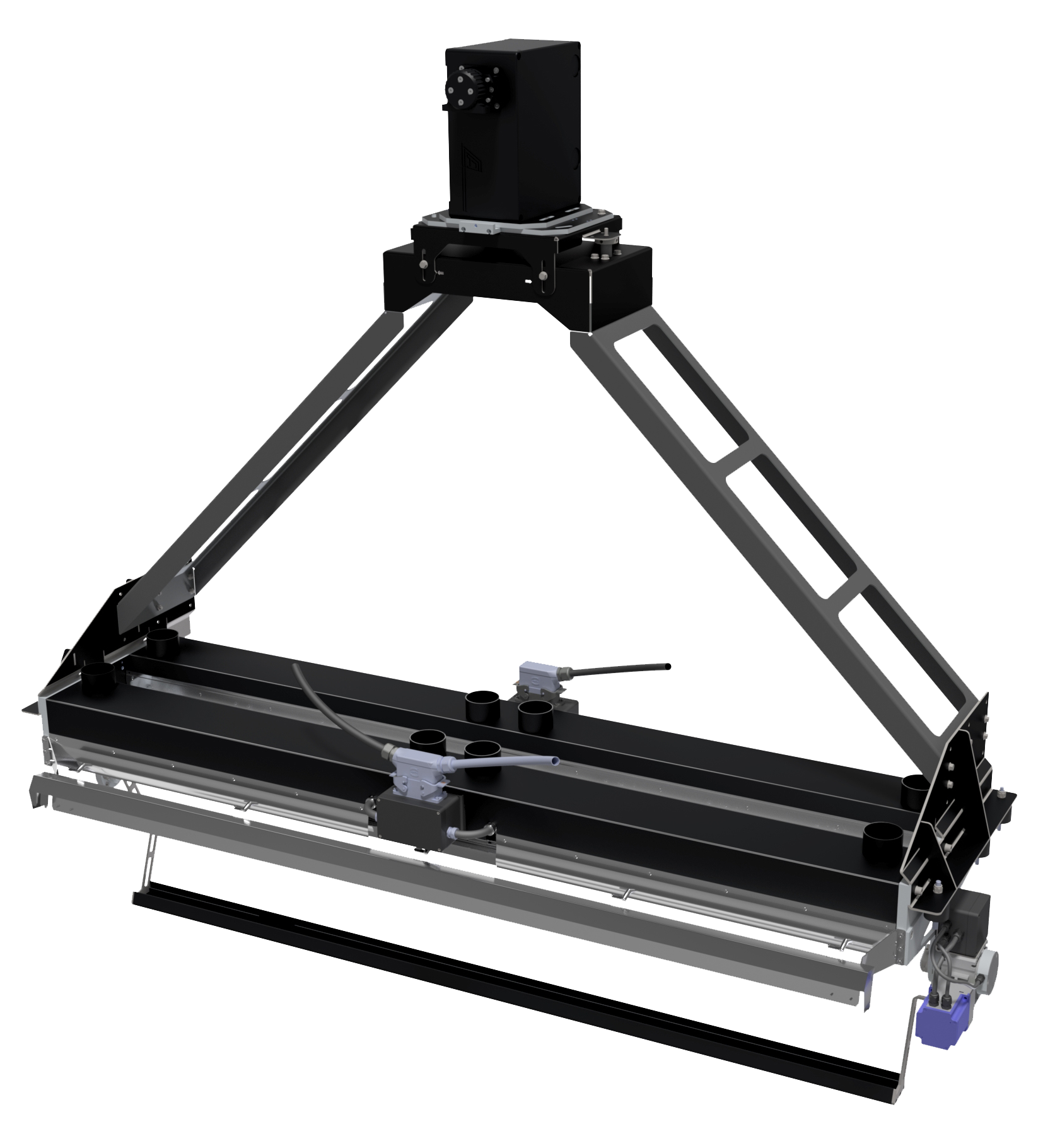

The XRF-line X-ray fluorescence analyser is a turnkey solution for metal sorting, alloy identification, and materials analysis on moving conveyor belts. Designed for industrial processes, it provides fast, accurate, and non-destructive analysis of metals and metal alloys, enabling precise sorting and process control.

Suitable for metal pieces larger than 1 cm or bulk material flows, the XRF-line determines average composition and metal concentrations, supporting upstream and downstream process optimisation.

Key Characteristics

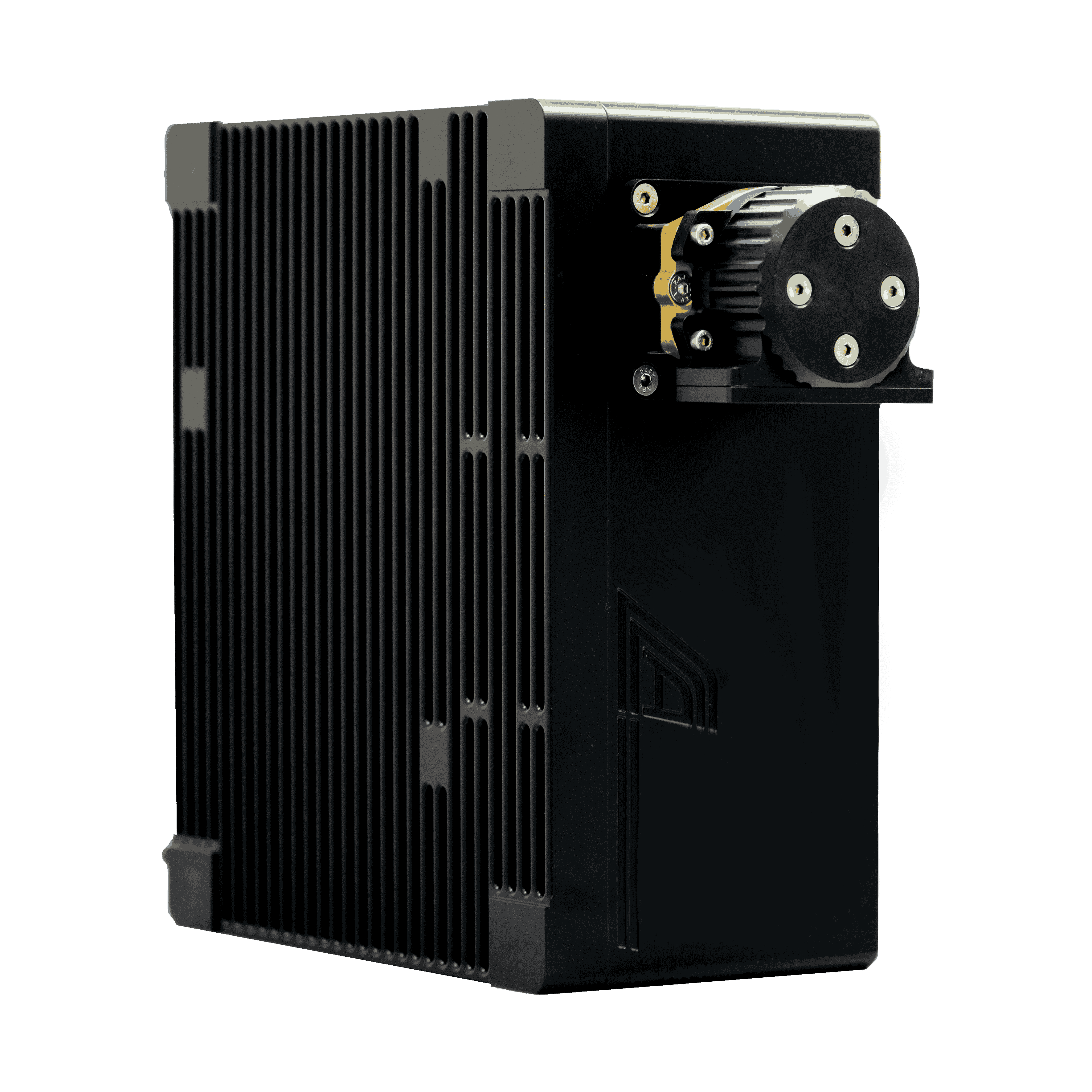

- State-of-the-art x-ray detector technology with Silicon Drift Detector (SDD)

- Fast real-time results (online process up to 100 Hz measurement speed)

- No sample preparation needed

- Non-contact, non-destructive detection

- Industrial PC including Windows®10 IoT OS

- Easy-to-use analysis routines for standard metal sorting applications included

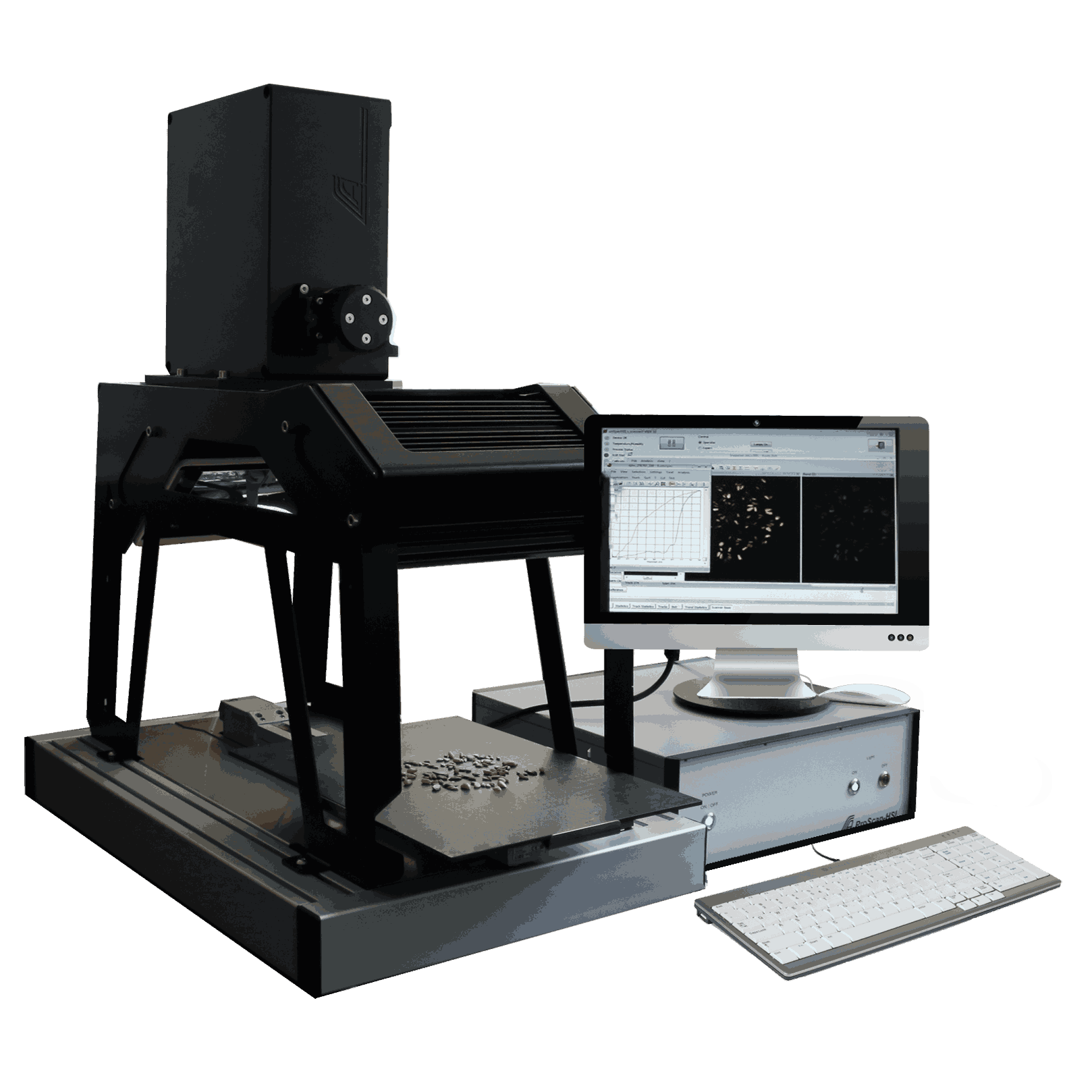

Software

- LLA provides a software package for setting up detectors and acquisition control.

- In Expert mode, the software configures detector settings such as measurement time, storage location, system calibration, and Gigabit Ethernet interface setup. It also enables monitoring of detector and system temperatures as well as humidity.

- In Operator mode you can change between pre-installed applications, check statistics on the sorting process or see a live picture of the belt.

Applications

XRF-line systems are configured for the identification and sorting of metals and metal alloys and can be used to:

- sort out impurities from material streams (meatballs, lead glass, etc.),

- sort by main components (iron, copper, gold, etc.),

- sort by alloy (copper, bronze, brass, etc.).

- identify valuble components (gold, platinum, rare earth elements)

- sort Incinerator Bottom Ash (IBA)

XRF-line systems are configured to determine the average composition or concentration of metals in a wide variety of material streams and can be used to:

- monitor input or output streams for process control,

- analyse input streams (scrap steel, etc.),

- analyse output streams (ore concentration, etc.).

Specification

Energy Range

3 – 30 keV (400 – 40 pm)

Detectable elements

Argon (Z = 18) to Uranium (Z = 92)

Number of measuring tracks

1 – 32 (depending on the application), typical 16

Typical track width

50 mm (minimal 25 mm)

Typical measuring distance

100 – 200 mm

Frame Rate

≤ 100 Hz (depending on the application)

X-ray tube

75 kV – 1000 W (water cooled)

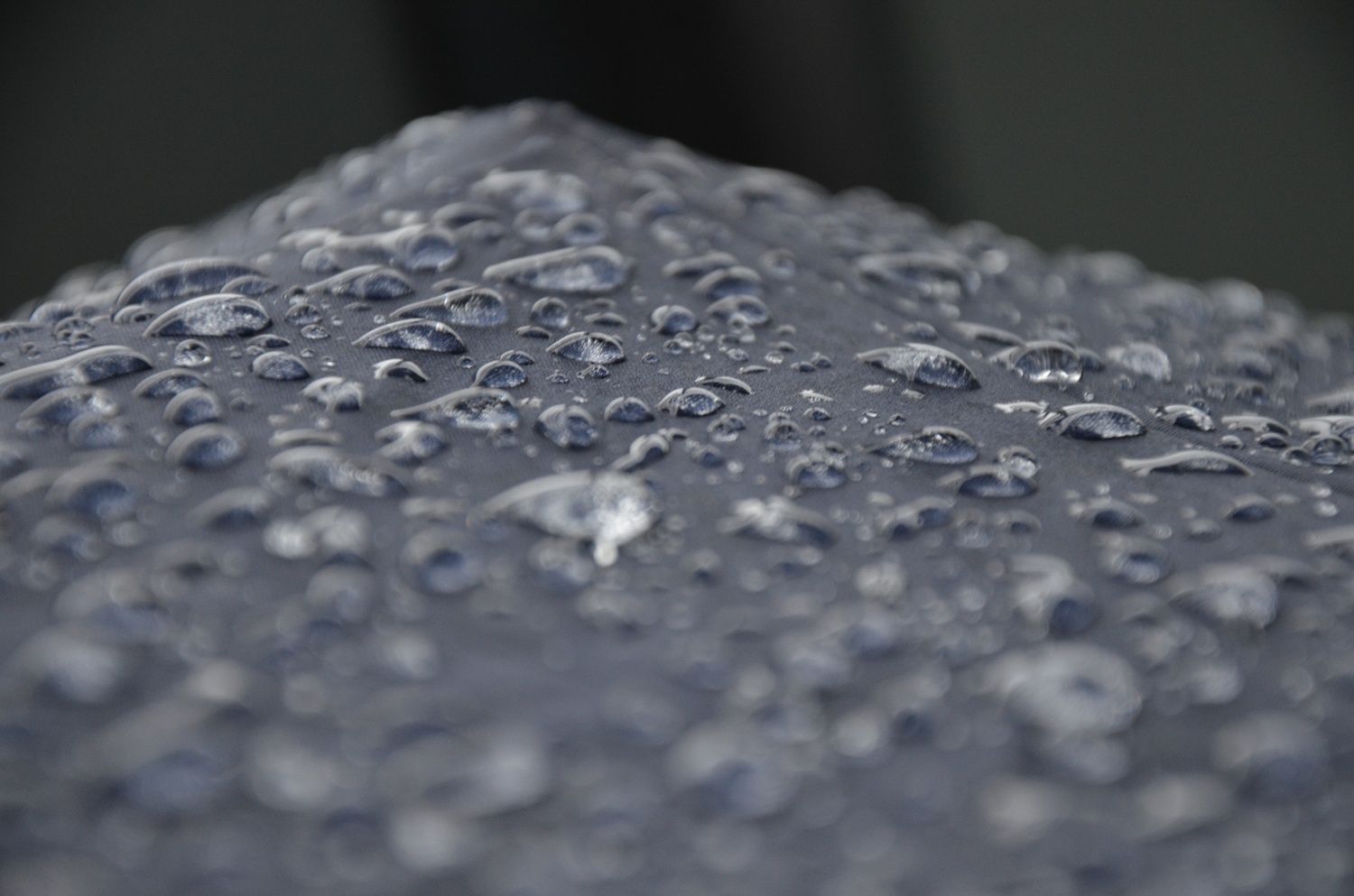

Protection class

IP64

Downloads

For more information on the XRF-line, please download the brochure resource.

Frequently Asked Questions

What is the XRF-line system used for?

The XRF-line is an x-ray fluorescence analyzer designed for metal sorting and materials analysis on moving conveyor belts. It identifies metals and metal alloys for automated sorting or process control.

What types of materials can the XRF-line analyze?

It can detect elements from Argon (Z=18) to Uranium (Z=92) and is suitable for sorting or analyzing metals and metal alloys, including iron, copper, gold, bronze, brass, and more.

How large must metal pieces be for sorting?

The system is ideal for metal pieces larger than about 1 cm in diameter. Smaller particles can still be analyzed when determining average composition in material flows.

Is the XRF-line suitable for harsh industrial environments?

Yes. With a protection class of IP64, the system is dust- and splash-resistant. It also features a water-cooled 75 kV – 1000 W x-ray tube for robust industrial operation.

What are typical applications for the XRF-line?

Applications include: – Sorting metal alloys – Removing impurities such as meatballs or lead glass – Sorting by main metal component (e.g., Cu, Fe, Au) – Monitoring input/output streams for process control – Analyzing scrap steel, ore concentration, and other material streams

How fast can the XRF-line measure?

The system provides real-time results with measurement speeds of up to 100 Hz, making it suitable for high-throughput continuous industrial processes.

Does the XRF-line require sample preparation?

No. It performs non-contact, non-destructive, and preparation-free measurements directly on the conveyor belt.

What are the operating distances for measurement?

Typical measuring distances range from 100 to 200 mm, ensuring flexible integration into various conveyor systems.

What software features are included?

LLA provides software with two modes: – Expert Mode: Configure detector settings, measurement time, calibration, data storage, Gigabit Ethernet setup, and monitor temperature/humidity. – Operator Mode: Switch between applications, view sorting statistics, and monitor a live conveyor belt image.

How many measuring tracks are available?

Depending on configuration, the system supports 1–32 measuring tracks, with 16 tracks typical, each with a typical track width of 50 mm.

More spectrometers and cameras

Request more information

LLA Instruments GmbH

Justus-von-Liebig Straße 9/11

12489 Berlin

Germany

For Service Enquiries