Home / Applications / Metal Sorting

Metal Sorting

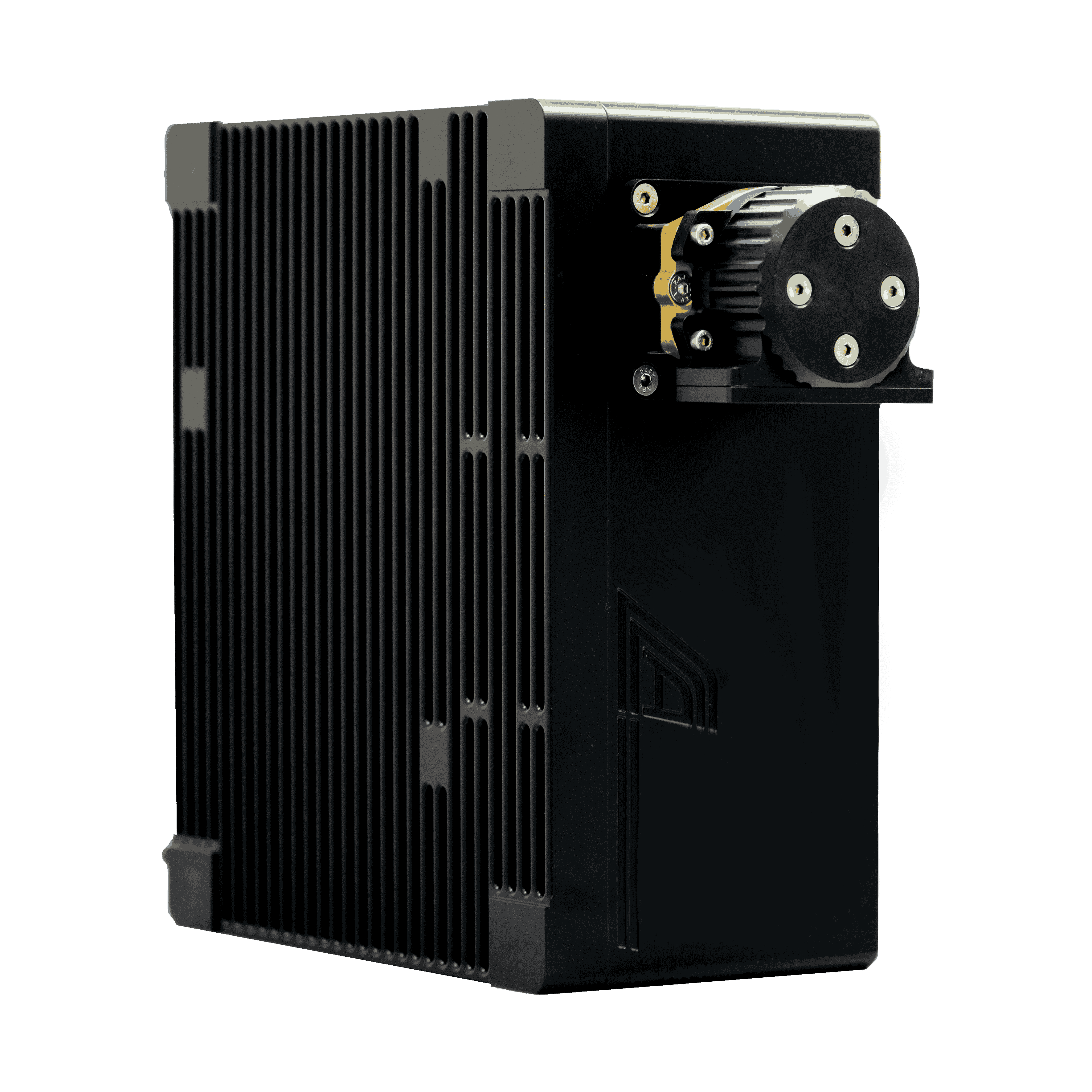

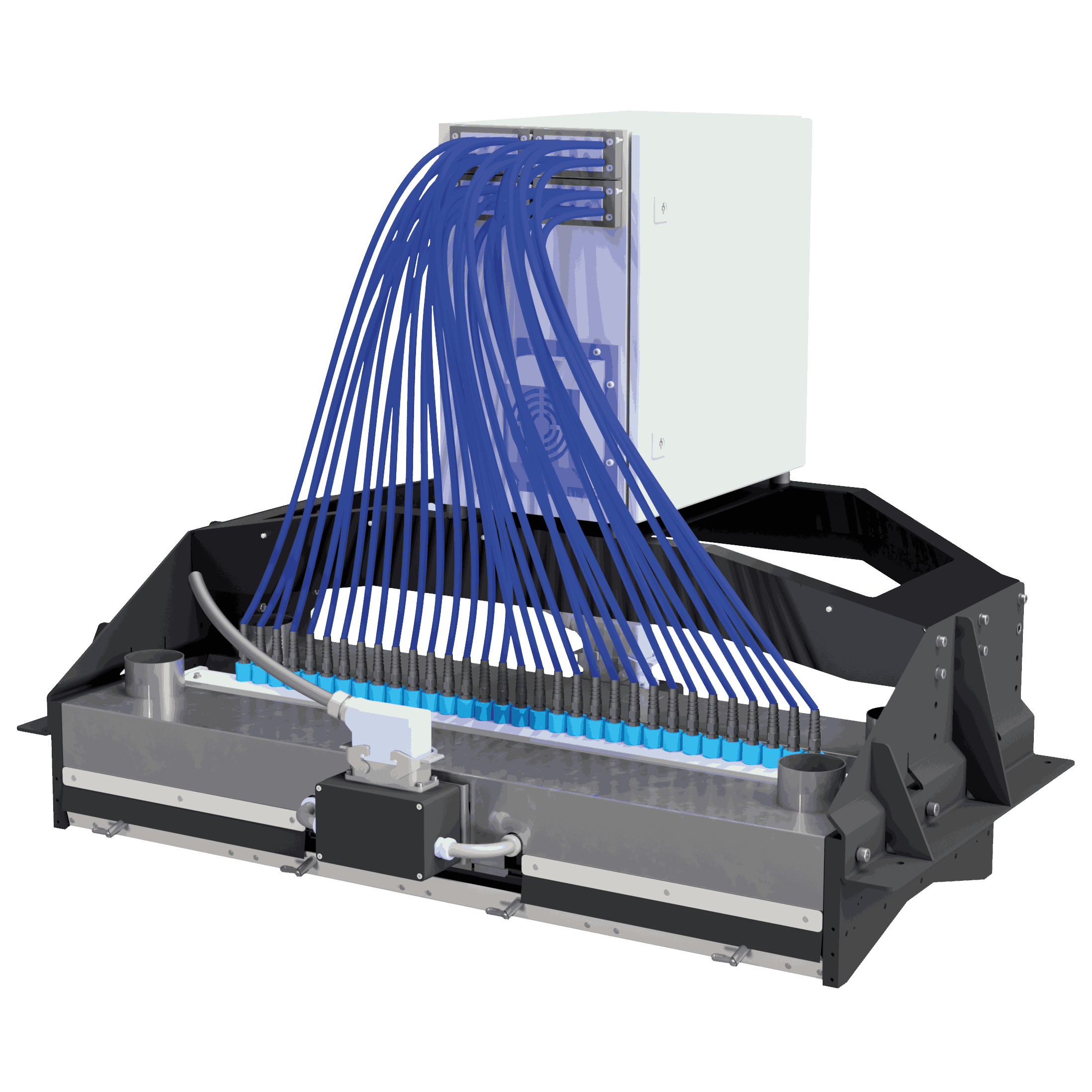

High-speed measurements for elemental real-time analysis

Through real-time elemental analysis, our XRF-line systems enable you to perform quality control or sorting of metal streams in harsh industrial environments. While doing so, analysis is independent to a large extent of moisture and organic impurities as well as coatings and paints. It also possible to partially correct for the influence of metallic coatings.

LLA offers applications involving the sorting of material streams into fractions, such as glass, ferrous and non-ferrous scrap, as well as additional sorting into fractions with significantly higher degree of purity and value such as Zebra, Zorba, Zurik, etc.

We will gladly develop individual analysis algorithms tailored to your application. Please feel free to contact us with your specific application! We will develop a suitable solution that matches your requirements.

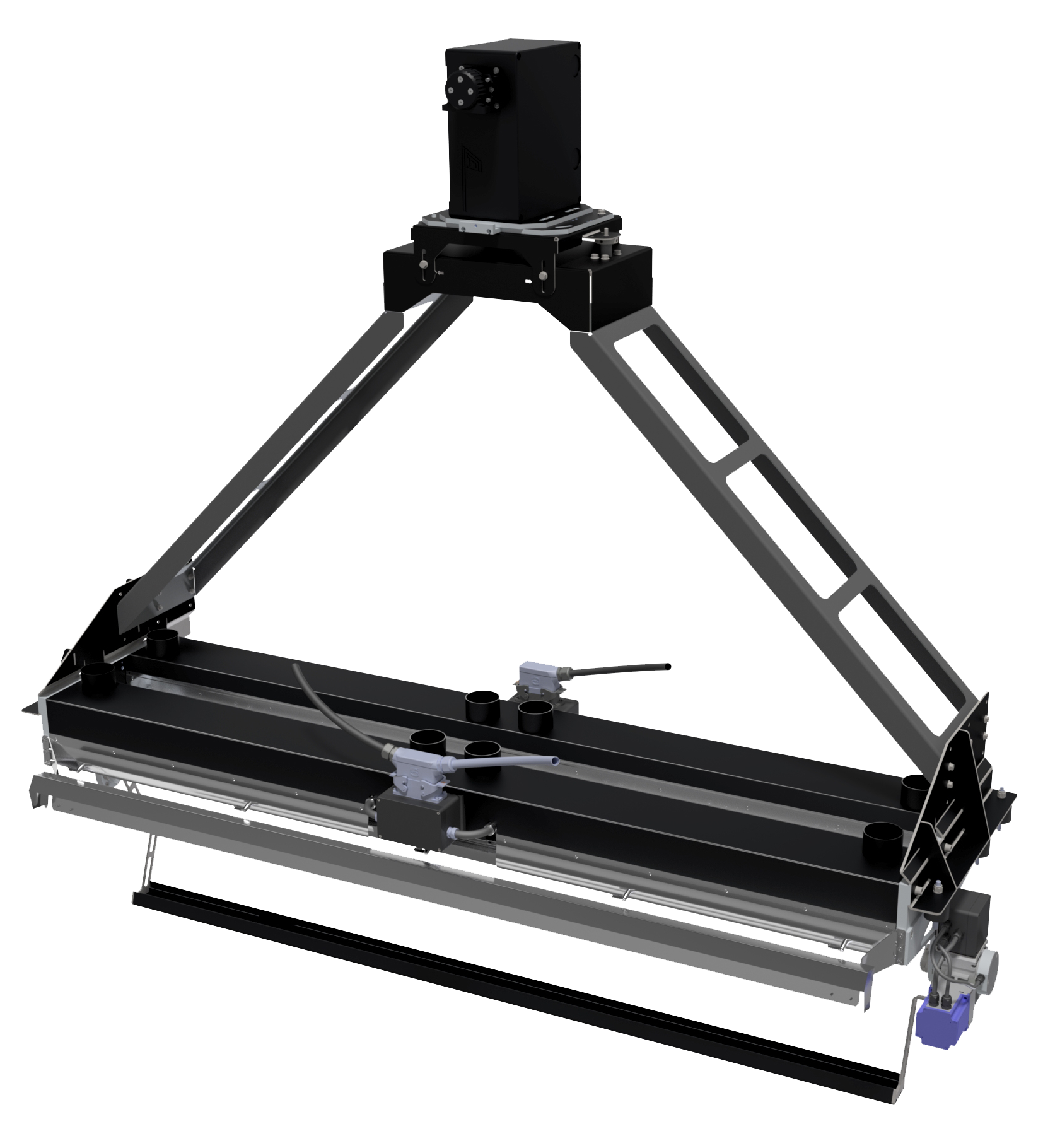

Metal sorting

Suitable x-ray fluorescence technology for industrial sorting:

- end-of-life vehicles (ELV)

- white goods (washing machines, refrigerators, etc.)

- construction waste (steel, pipes, cables, etc.)

- electrical waste (steel casings, etc.)

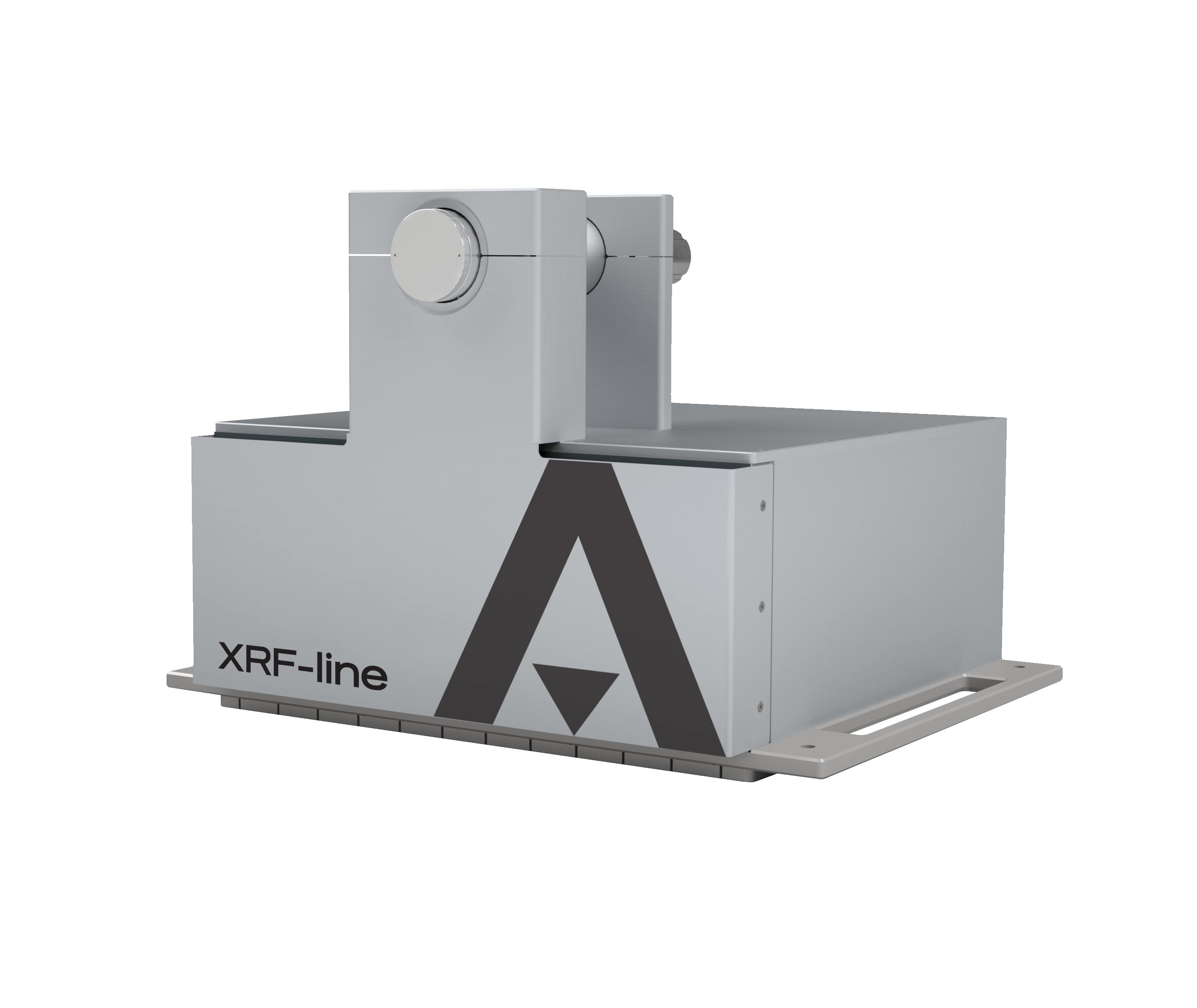

WE RECOMMEND: Our measuring system XRF-line for any of these applications.

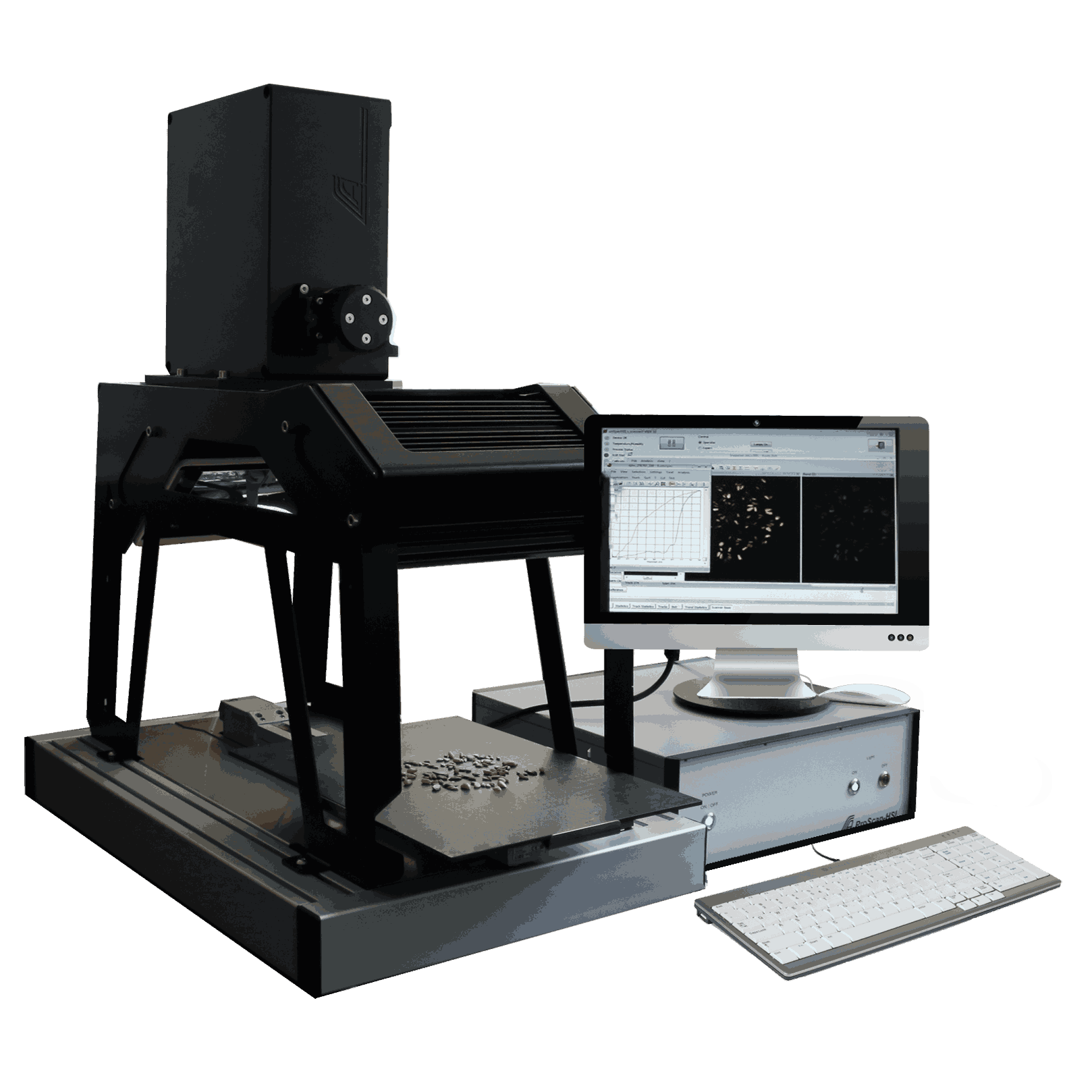

Sorting of material streams into alloys

For industrial sorting based on material classes or alloys:

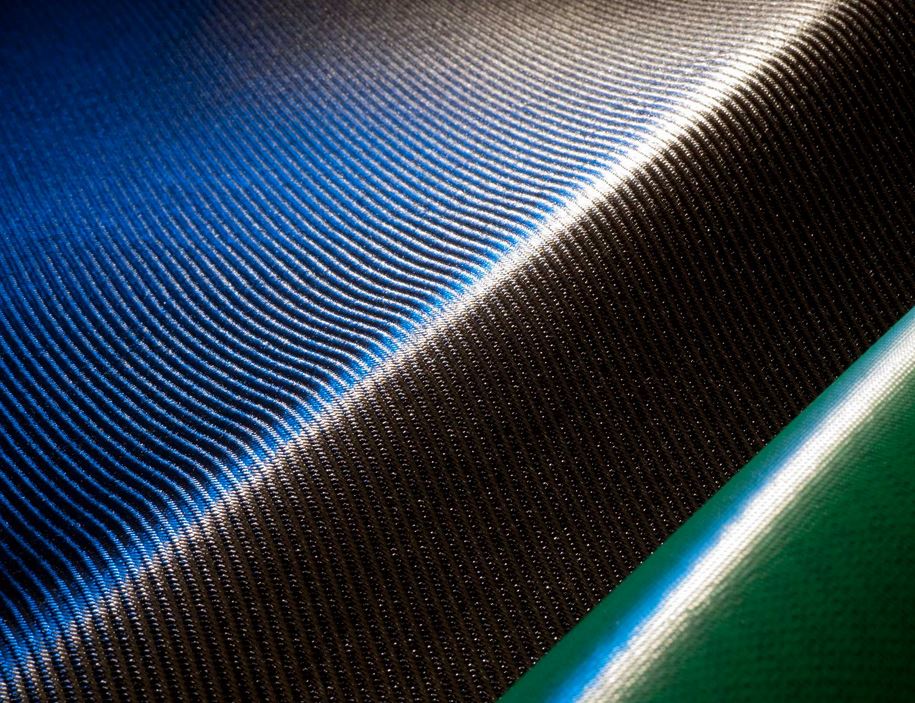

Sorting of Zebra, Zorba, and Zurik into high concentrated fractions of bronze, brass, copper and non-magnetic stainless steel. Additional sorting of stainless steel, bronze, or brass fractions into subclasses, e.g., separating 1.4372 (AISI 201) from 1.4301 (AISI 304).

WE RECOMMEND: Using our X-ray fluorescence measurement technology to improve sustainable use of resources, to implement processes effectively, and to optimise purity levels and value.

In-process monitoring of material streams

For quality control and process control:

Monitoring of input streams (steel mills,…)

Monitoring of output streams (harmful contaminations,…)