Home / Products / Illumination Units

Illumination Units

for KUSTA hyperspectral cameras and KUSTA-MPL multiplexed NIR spectrometers

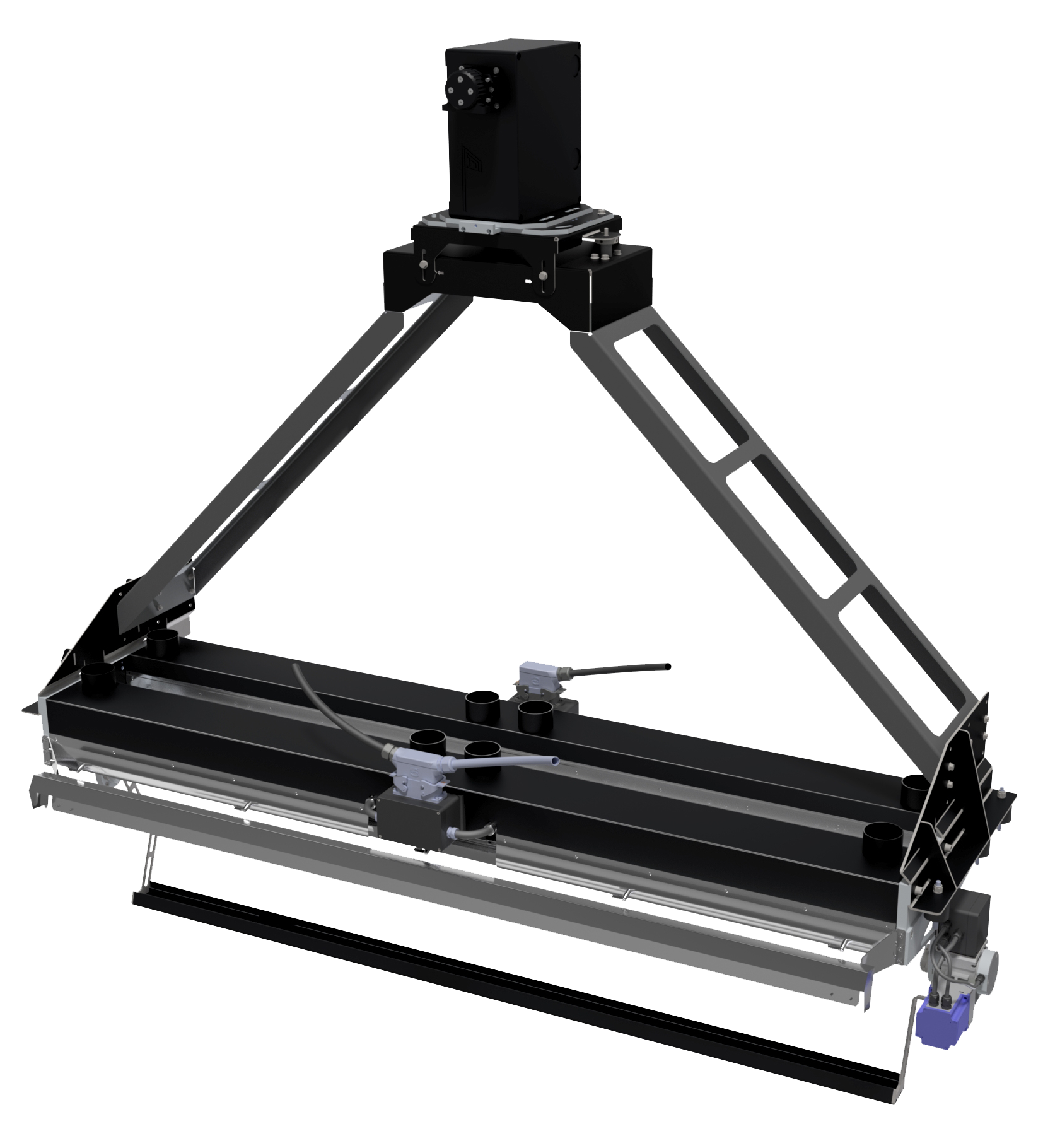

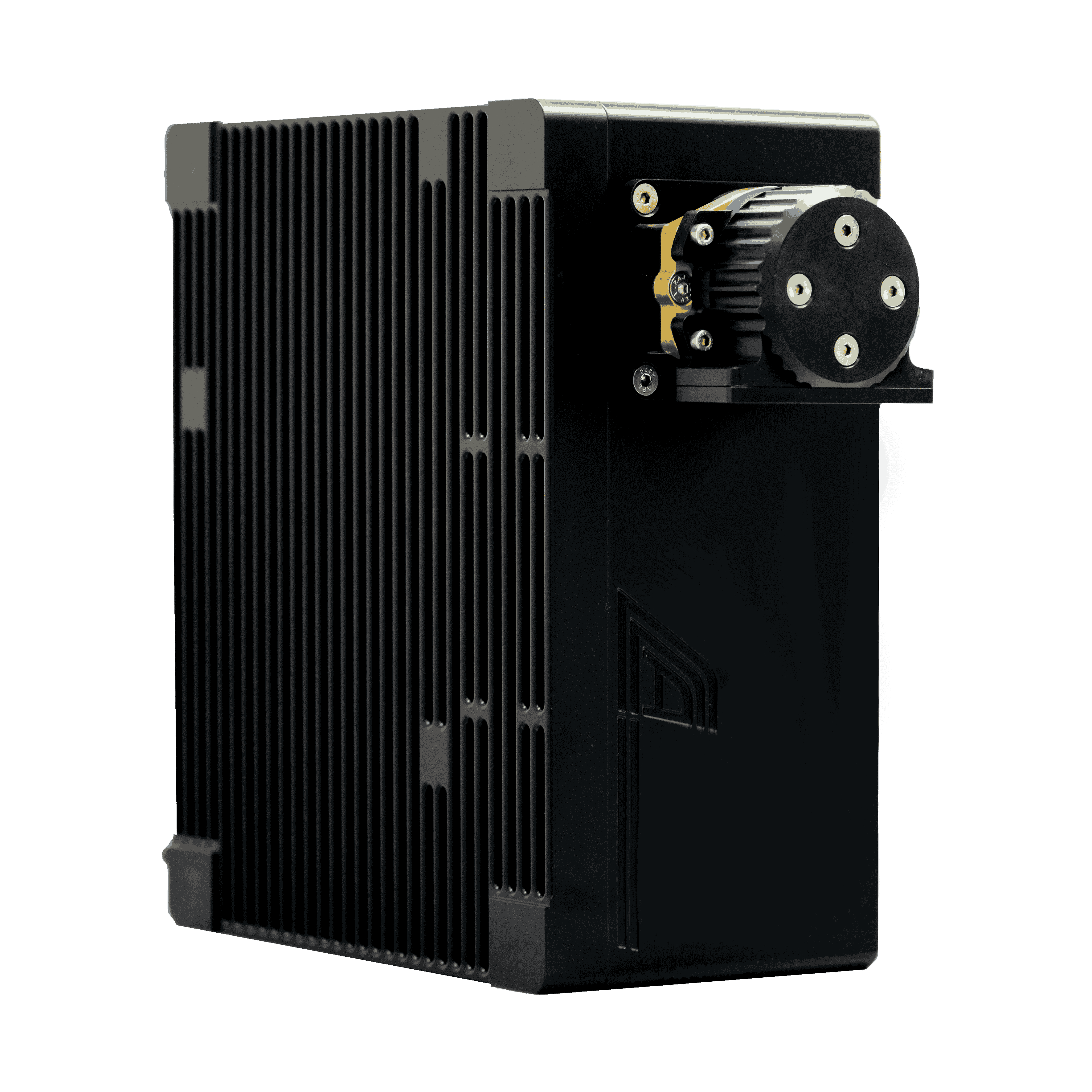

PMAmsi Illumination Units

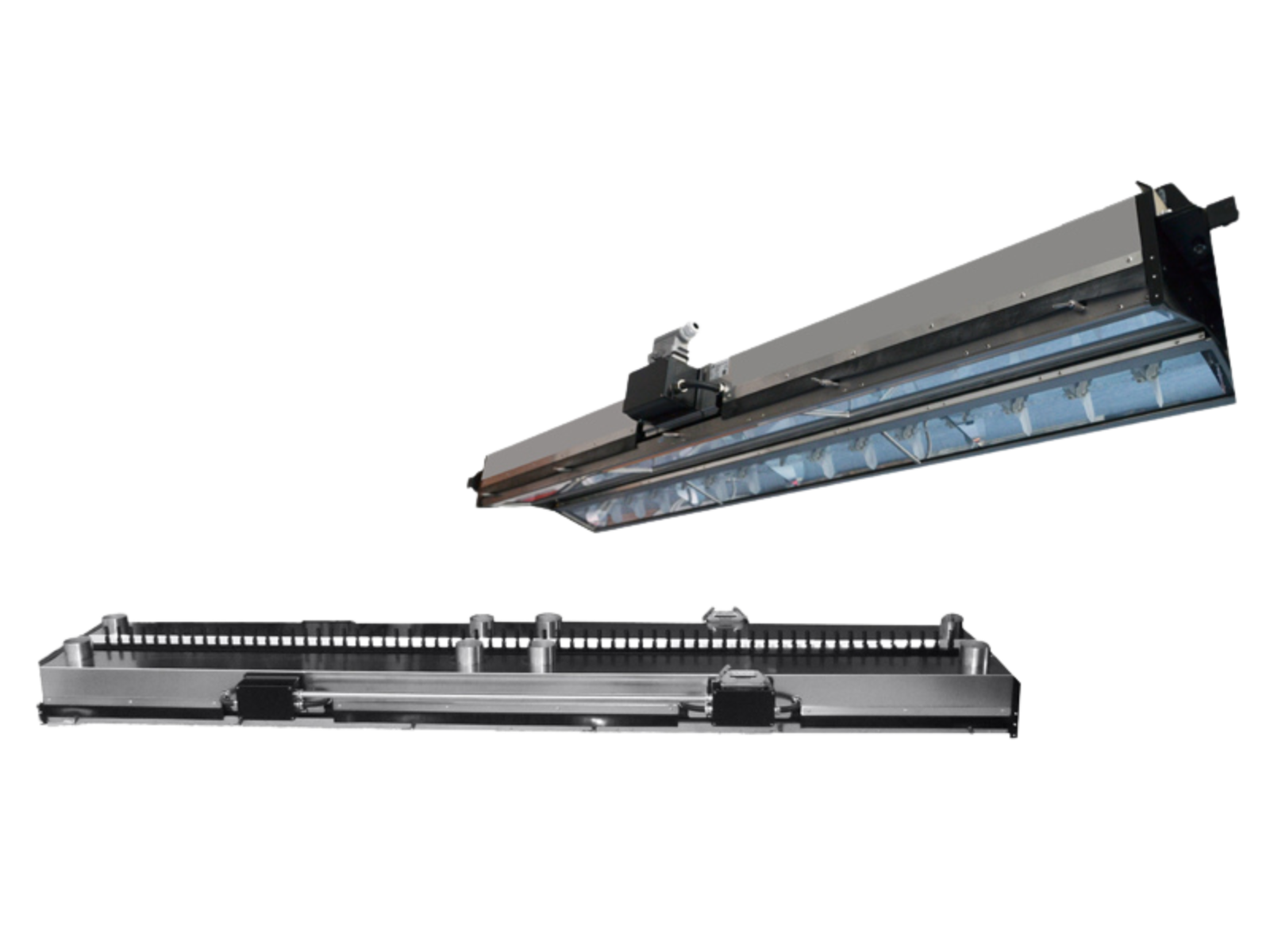

The illumination unit PMAmsi is used for the identification of diffusely reflecting NIR active substances in the production process in connection with the KUSTA hyperspectral camera.

The system is suitable for opaque, non-black material as well as for semi-transparent, only partially reflecting materials. The illumination unit is installed above the conveyor belt with the material to be sorted.

The measuring distance of 500 mm is particularly suitable for plastic sorting or other sorting applications in recycling.

The measuring distance of 300 mm is suitable for sorting smaller particles, such as PET flakes. The measurement is done contactless from above while the sorting material passes under the illumination. Optionally, the illumination unit is supplied with a mounting bridge. This enables the precisely definable alignment of the illumination unit and the hyperspectral camera.

Key characteristics

- Double-sided illumination, focused on measurement level

- Measurement width from 500 mm up to 2800 mm

- Illumination area at 500 mm distance: 40 mm x measurement width

- NIR light source from Halogen light bulbs, 230 V or 120 V versions

- Protection level IP65

Components

The illumination unit PMAmsi consists of two parallel illumination lines (LU) which are slightly inclined to each other. This two-sided illumination of the material stream minimises shadowing and thus increases detection accuracy. The internal NIR emitters create a common narrow strip of light on the conveyor belt. The two illumination lines are connected at the end with a mounting plate.

Set Up

The illumination unit is offered in the following standard lengths:

- 1000 mm, 1600 mm, 2000 mm; and 2800 mm for operation with two NIR cameras.

- Special lengths between 500 mm and 2000 mm are available in 200 mm increments on request.

The following reflector variants are available:

- LR50 for 500 mm measuring distance

- LR30 for 300 mm measuring distance.

Optional

- Cooling air guide recommended for an ambient temperature > +45 °C

- 115 V variant available Illumination PMAmsi.

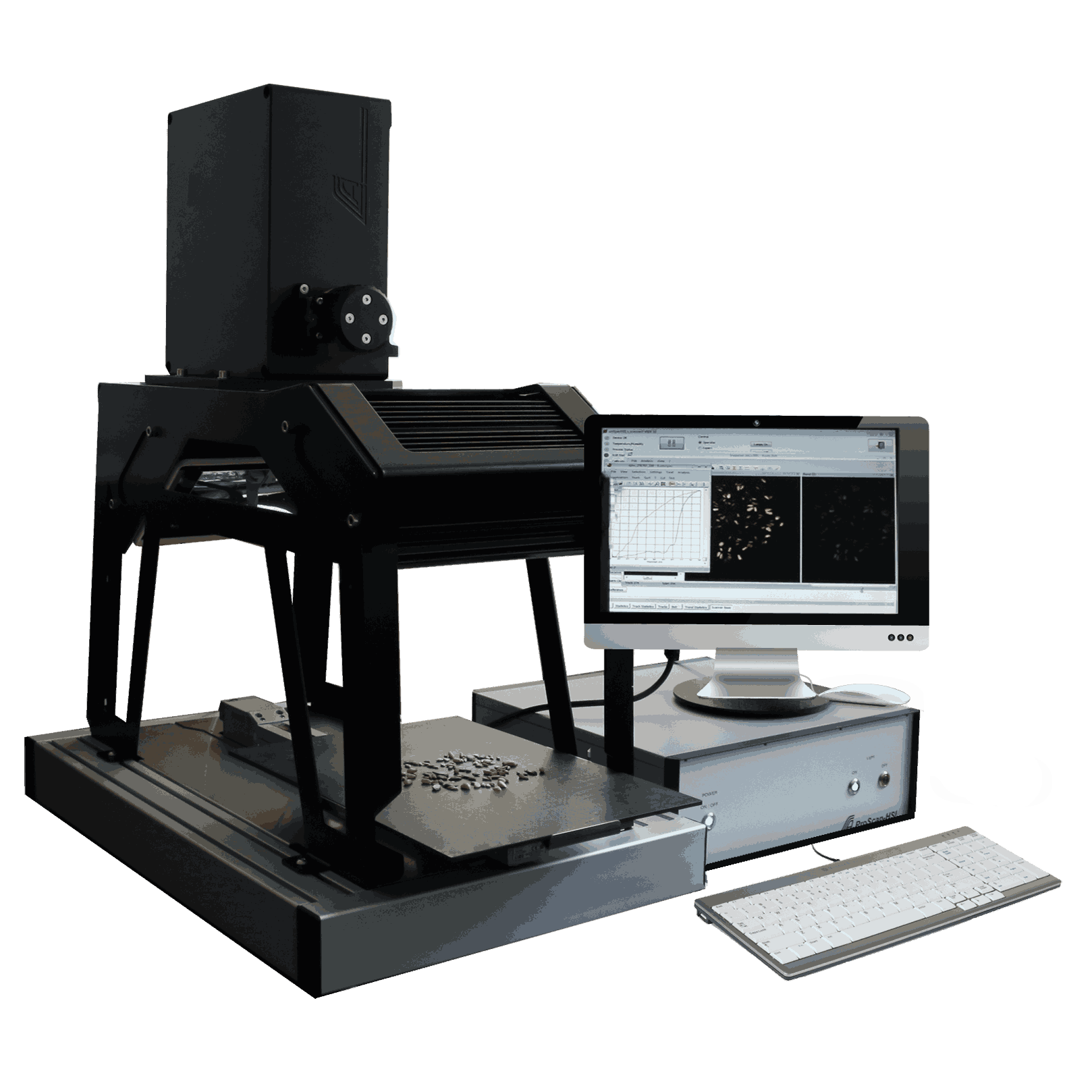

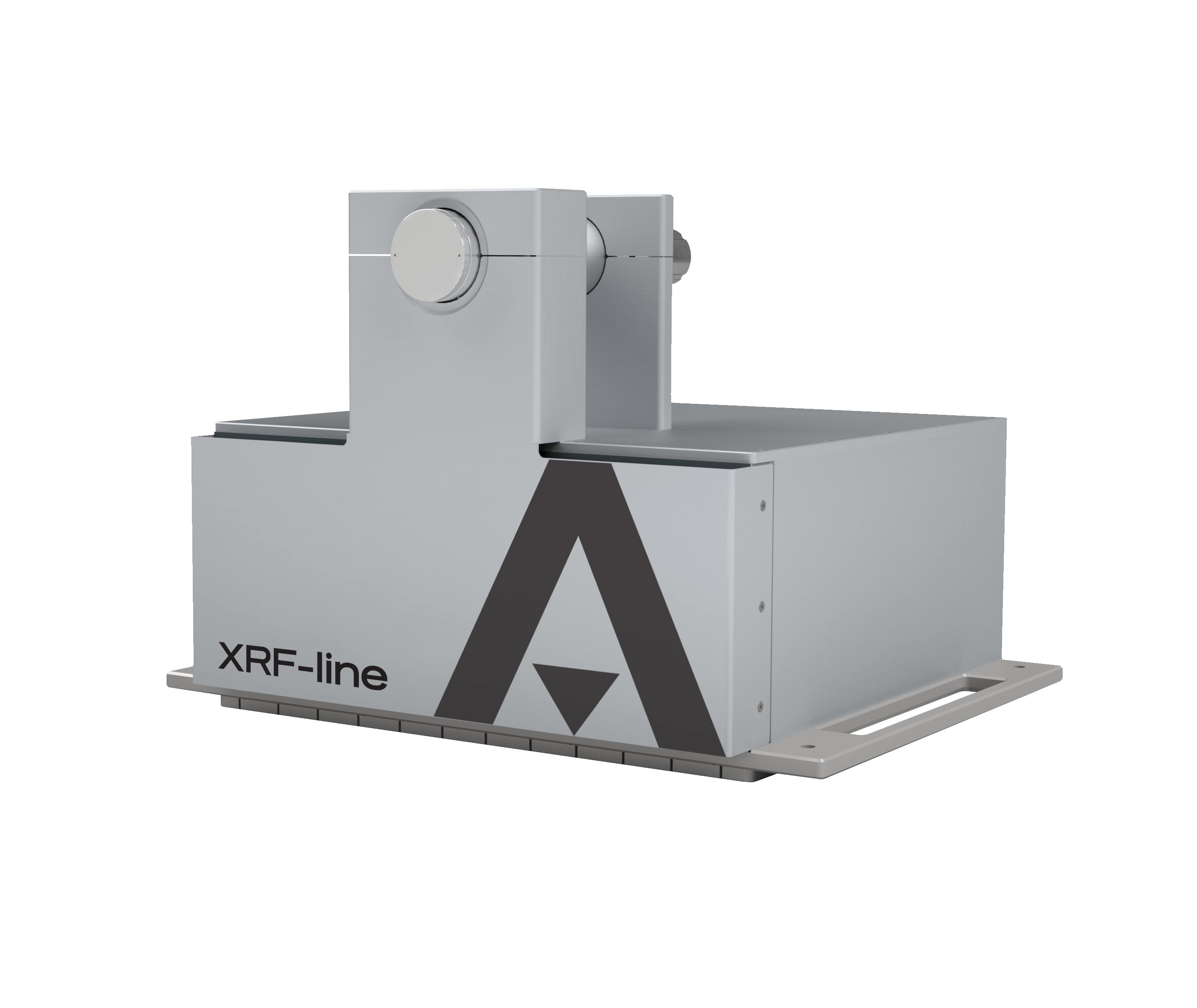

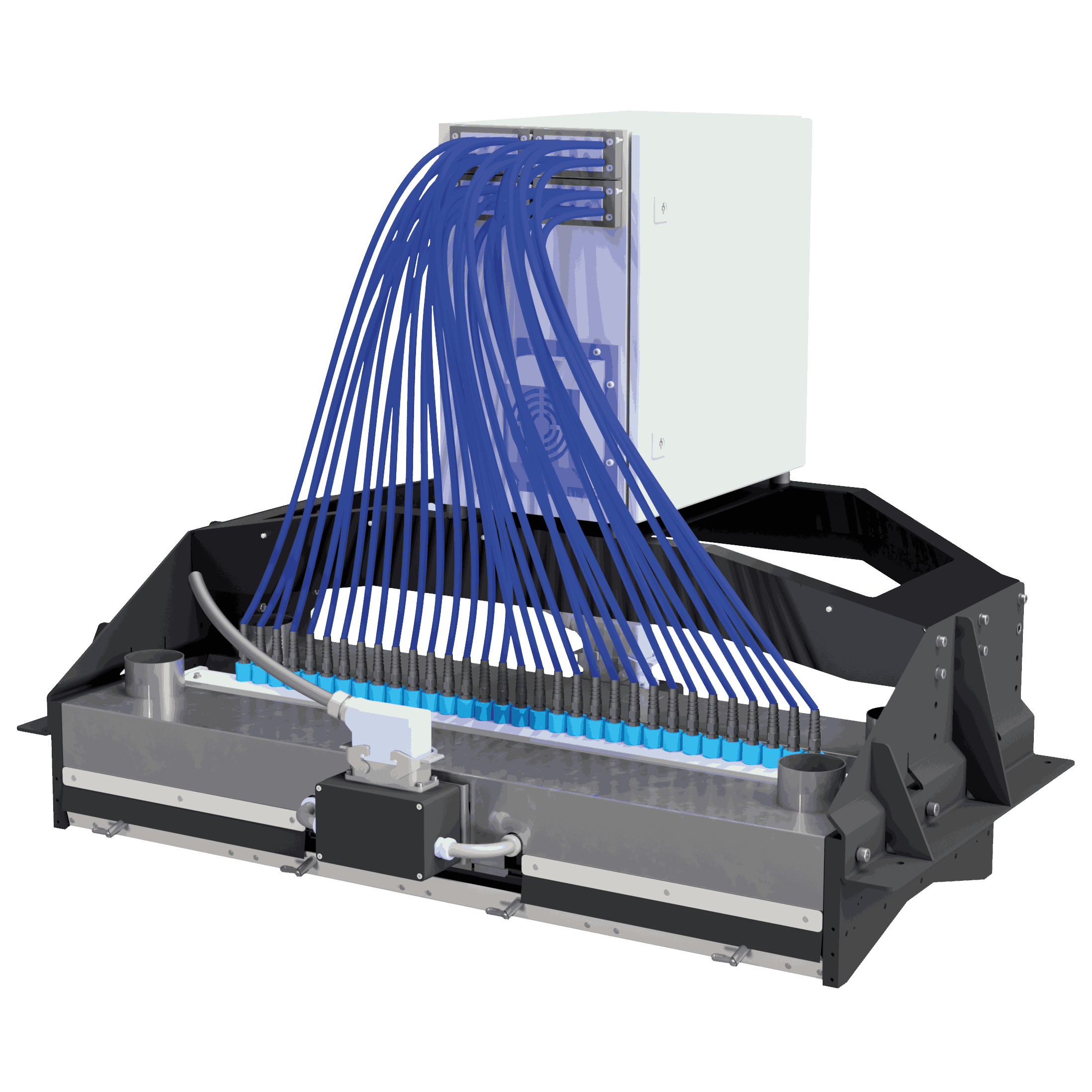

PMAmpl Illumination Unit / Process Probes

The PMAmpl process probes collect the light remitted by the samples or transmitted through the samples. The light is transmitted to the spectrometer via fibre optic cables. Measuring probe lines are available to suit the respective application. The correspondingly designed measuring probe lines are connected to the KUSTA-MPL multiplexed NIR spectrometer.

Key characteristics

- Remission measurement method

- Compact unit with Optic Line and double-sided Light Unit

- Measurement distance from 240 mm up to 500 mm

- NIR light source from Halogen light bulbs, 230 V or 120 V versions

Probe lines and components

The illumination unit PMAmpl consists of two parallel illumination units (LU) and an integrated optics lines (OL). All three elements are fixed by a plate at both ends. This double-sided illumination of the material flow minimises shadowing and thus increases detection accuracy. Mounting brackets allow the measuring unit to be mounted in a frame above the conveyor belt. Rubber buffers are included to dampen vibrations. Heat-resistant glass is fitted over the entire surface in front of the optics bar (OL) to protect it from discolouration and damage in the measuring headline. An active cooling cover and automatic calibration are available as options.

Customised design of probe lines

The design of the measuring probe lines is based on the following your specific requirements:

- Number of desired measuring tracks

- Speed of the material flow

- Measuring width for the entire material flow (conveyor belt width)

- Density of the material flow

- 120 V variant available

Set Up

- The probe lines are designed for measuring lengths from 500 mm up to 2800 mm.

- Standard lengths for conveyor belt widths are 1000 mm, 1600 mm, 2000 mm and 2800 mm.

- The measuring track pitch can be selected between typically 20 mm and 50 mm depending on the application.

- The coupling optics of the fibre optic cables realise a minimum measuring track width of 25 mm.

- Two versions are available to suit the material size: the vertical clearance is approx. 300 mm (LR30) or approx. 500 mm (LR50).

Request more information

LLA Instruments GmbH

Justus-von-Liebig Straße 9/11

12489 Berlin

Germany

For Service Enquiries