Contact Us

LLA Instruments GmbH

Justus-von-Liebig Straße 9/11

12489 Berlin

Germany

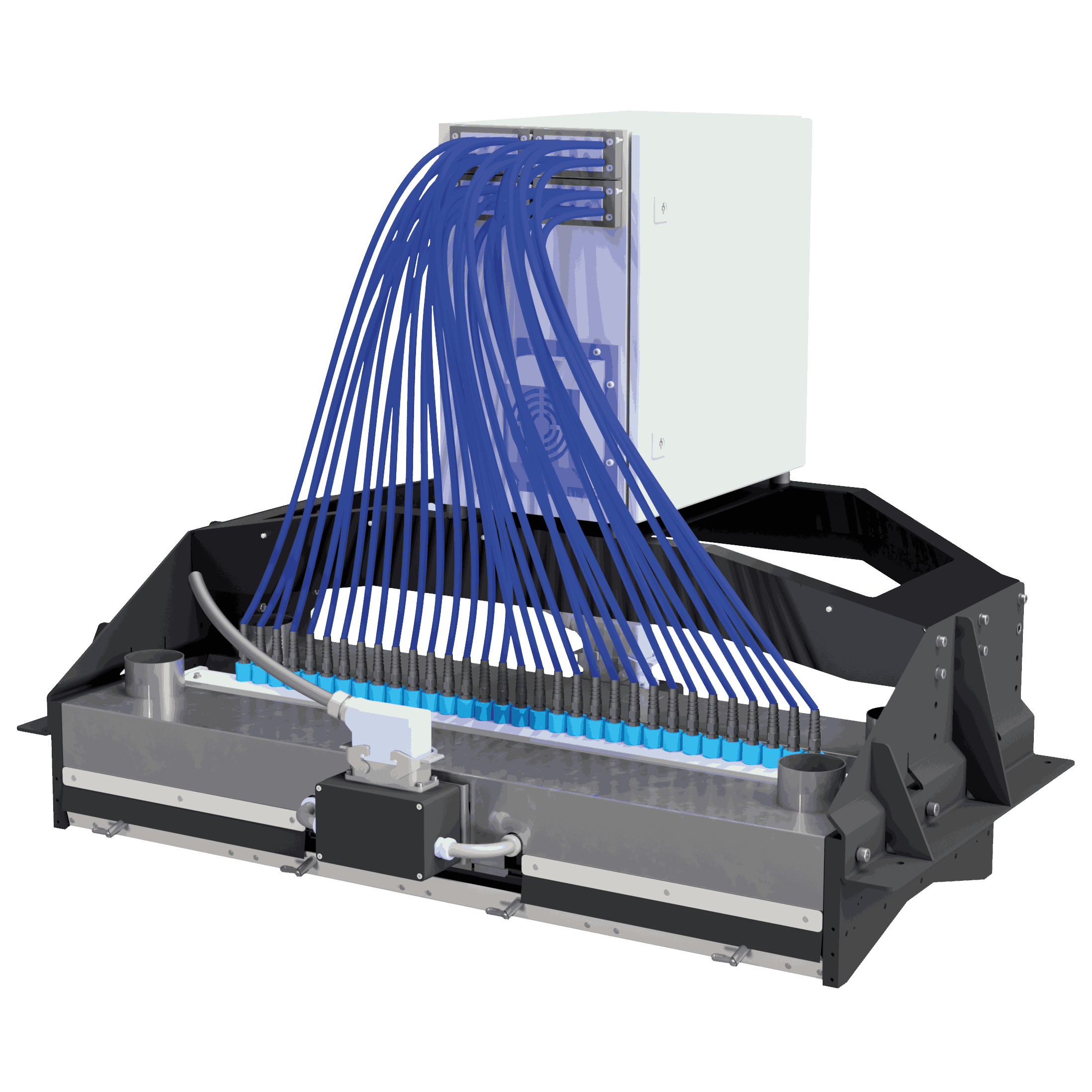

LLA Configurator

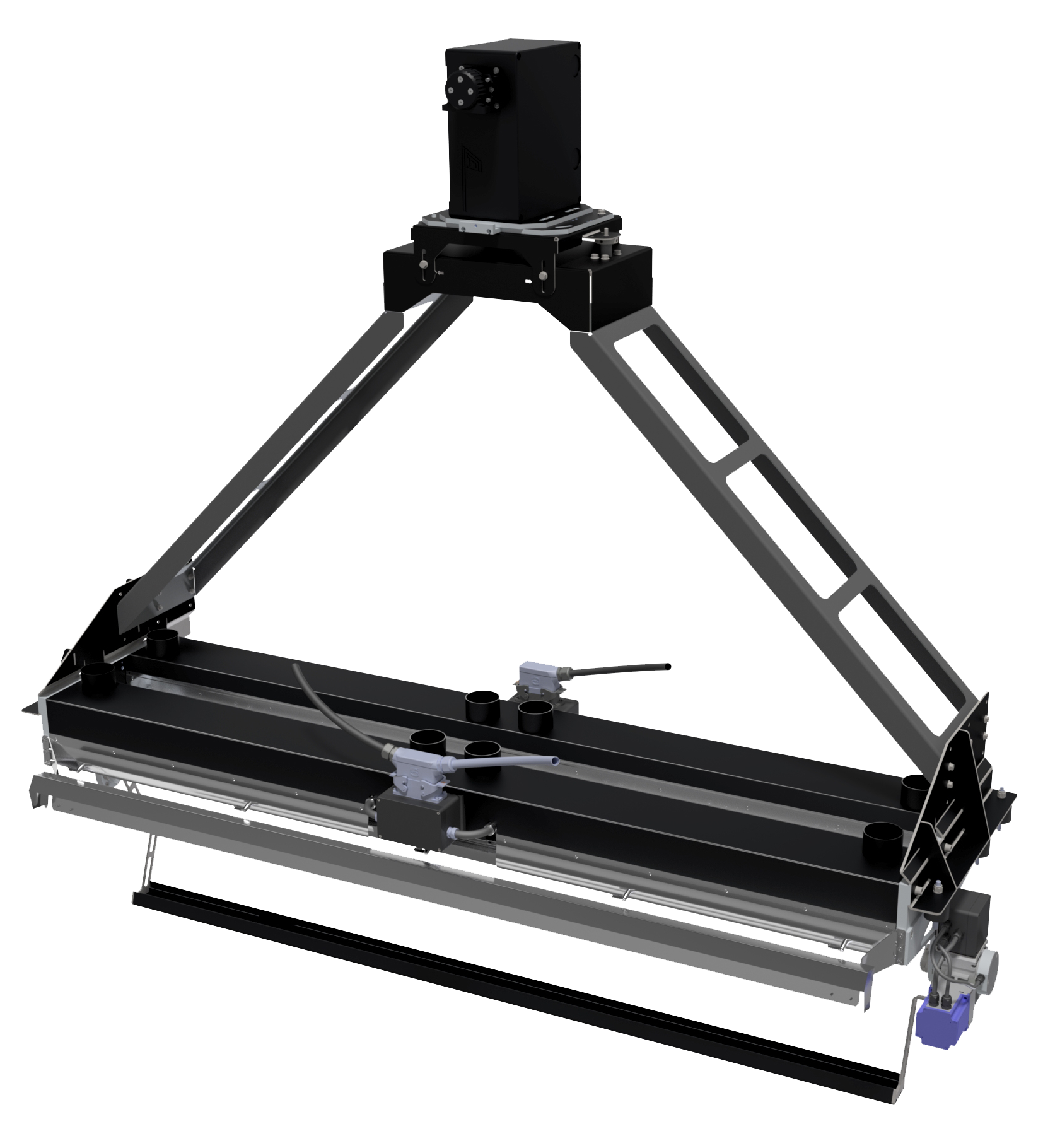

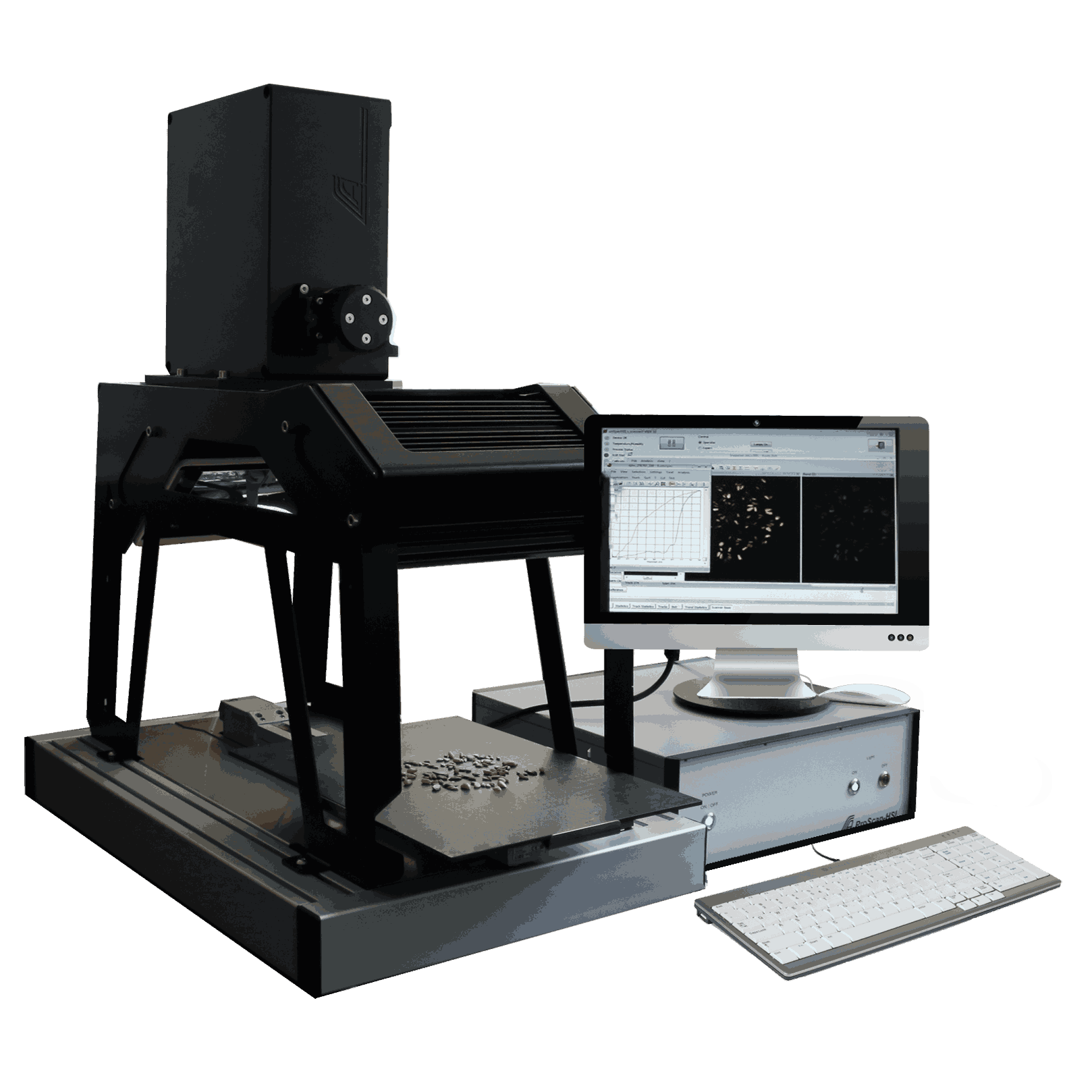

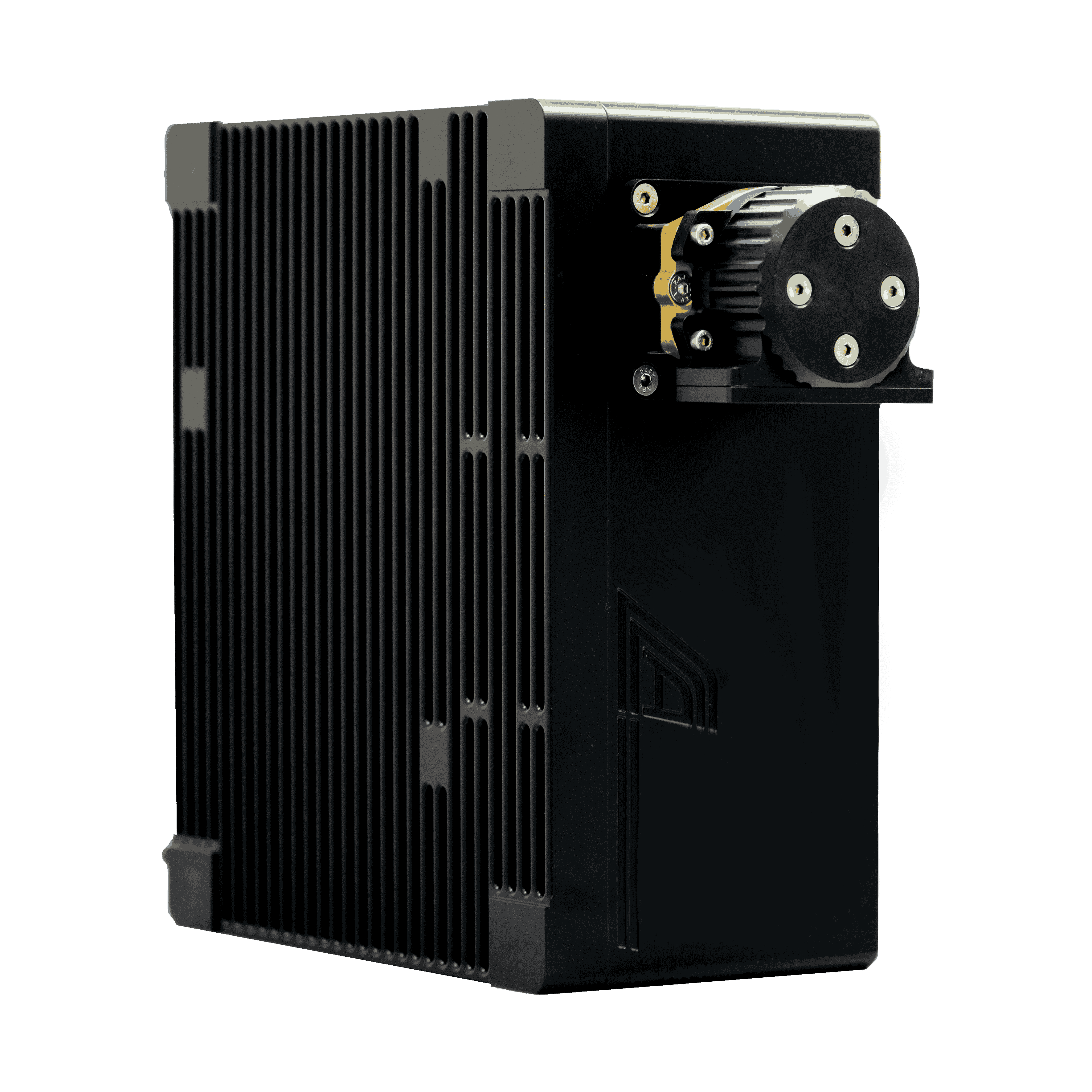

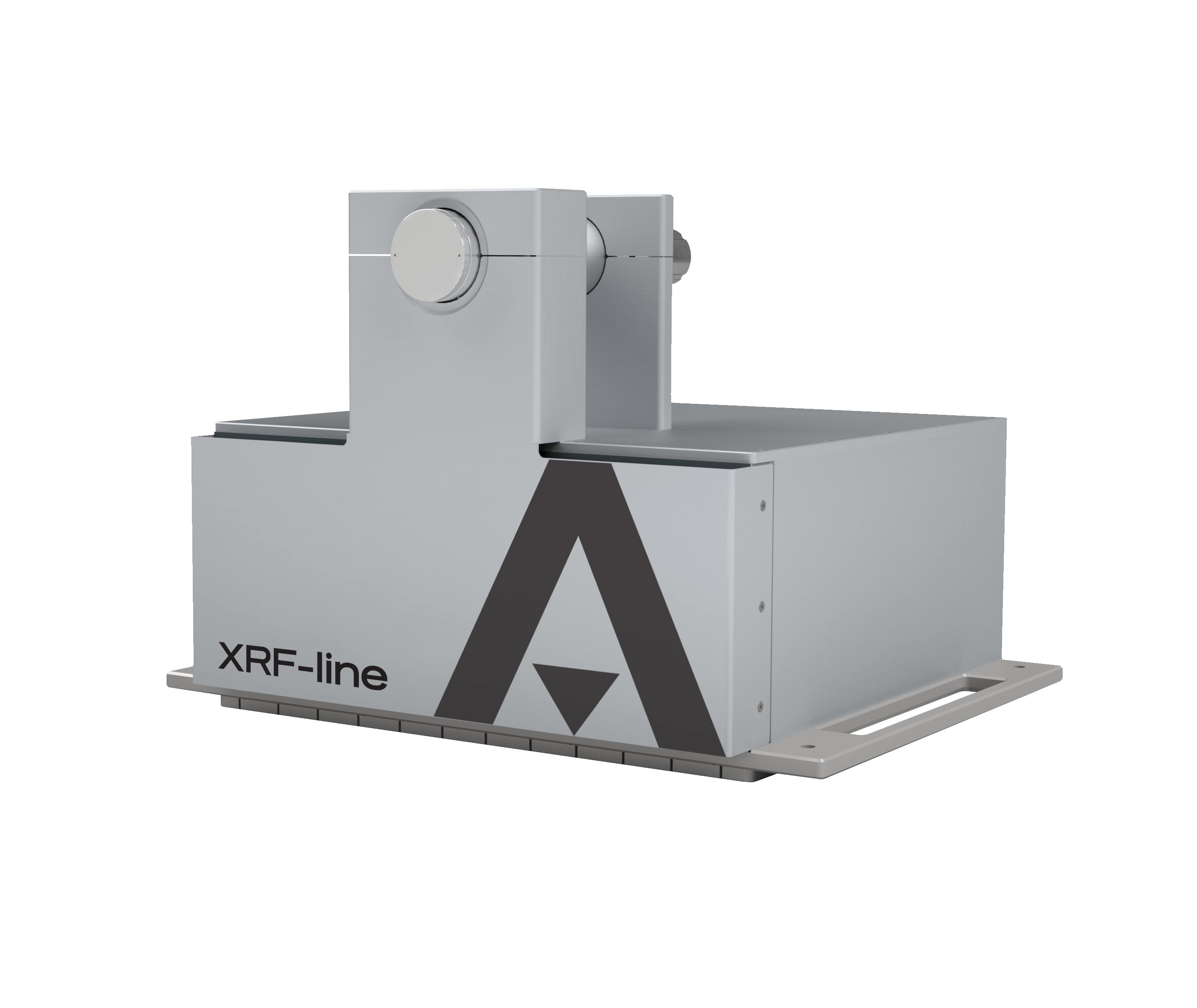

With the LLA Product Configurator you can easily configure your individual sorting measurement technology for plastics,construction waste, and paper.