Unlocking the Past with X-ray Fluorescence Technology: A Personal Story Meets Industrial Innovation

8 Apr 2025

At LLA Instruments, we’re passionate about the power of X-ray fluorescence (XRF) to transform how we understand materials—whether in cutting-edge recycling systems or uncovering the secrets of a family heirloom.

Last week, one of our Application Engineers received a truly special birthday gift: a 100-year-old metal wine cup, passed down from his grandfather. Naturally, curiosity took over—and he turned to X-ray fluorescence to learn more.

Using X-ray Fluorescence to Analyze Metal Composition

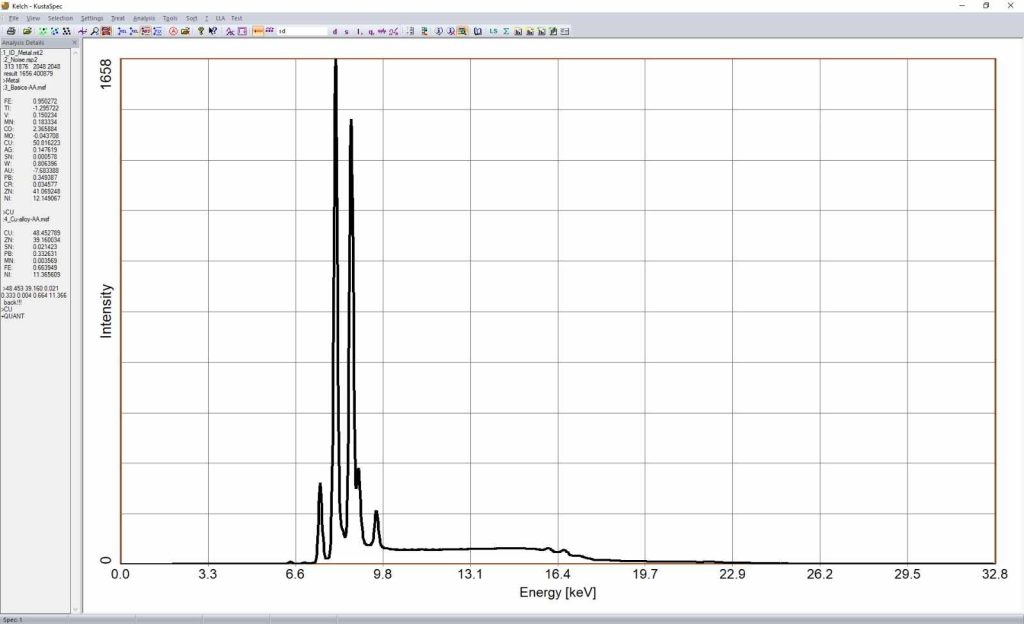

With access to our XRF-line analyzer, he performed a non-destructive test to determine the cup’s metal composition. The results were both surprising and fascinating, showing just how effective X-ray fluorescence can be for fast, accurate elemental analysis.

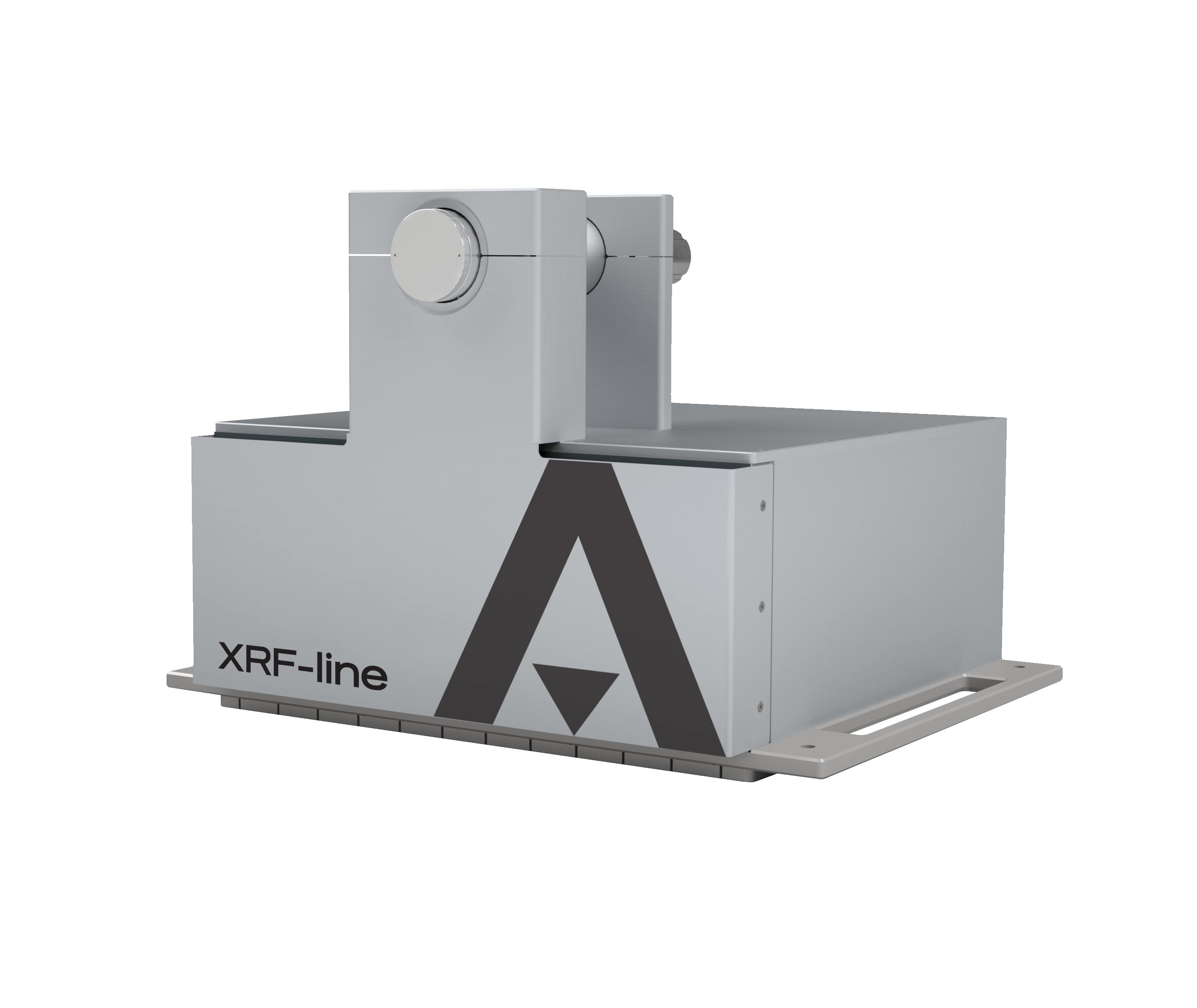

What Is the XRF-line System?

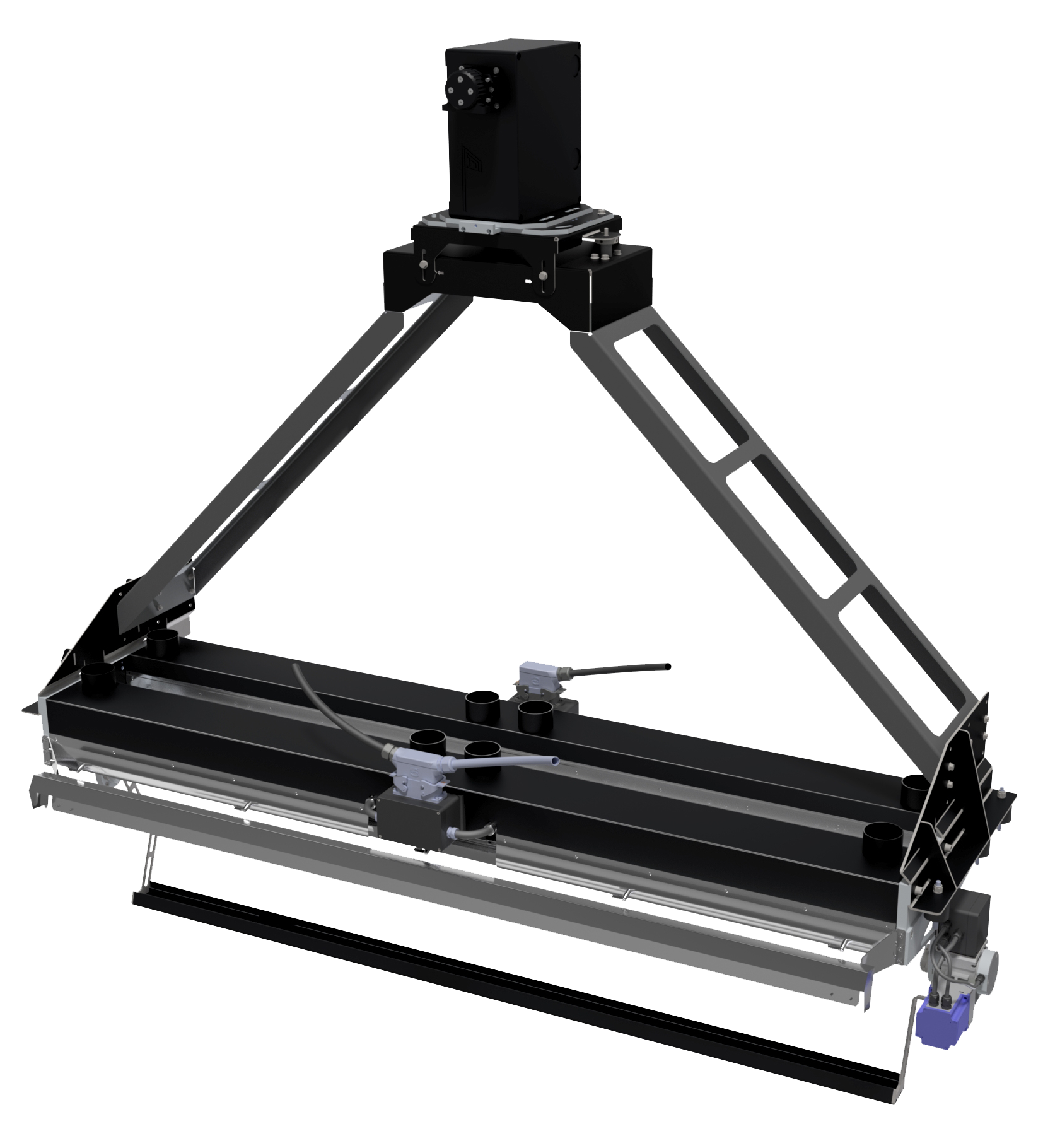

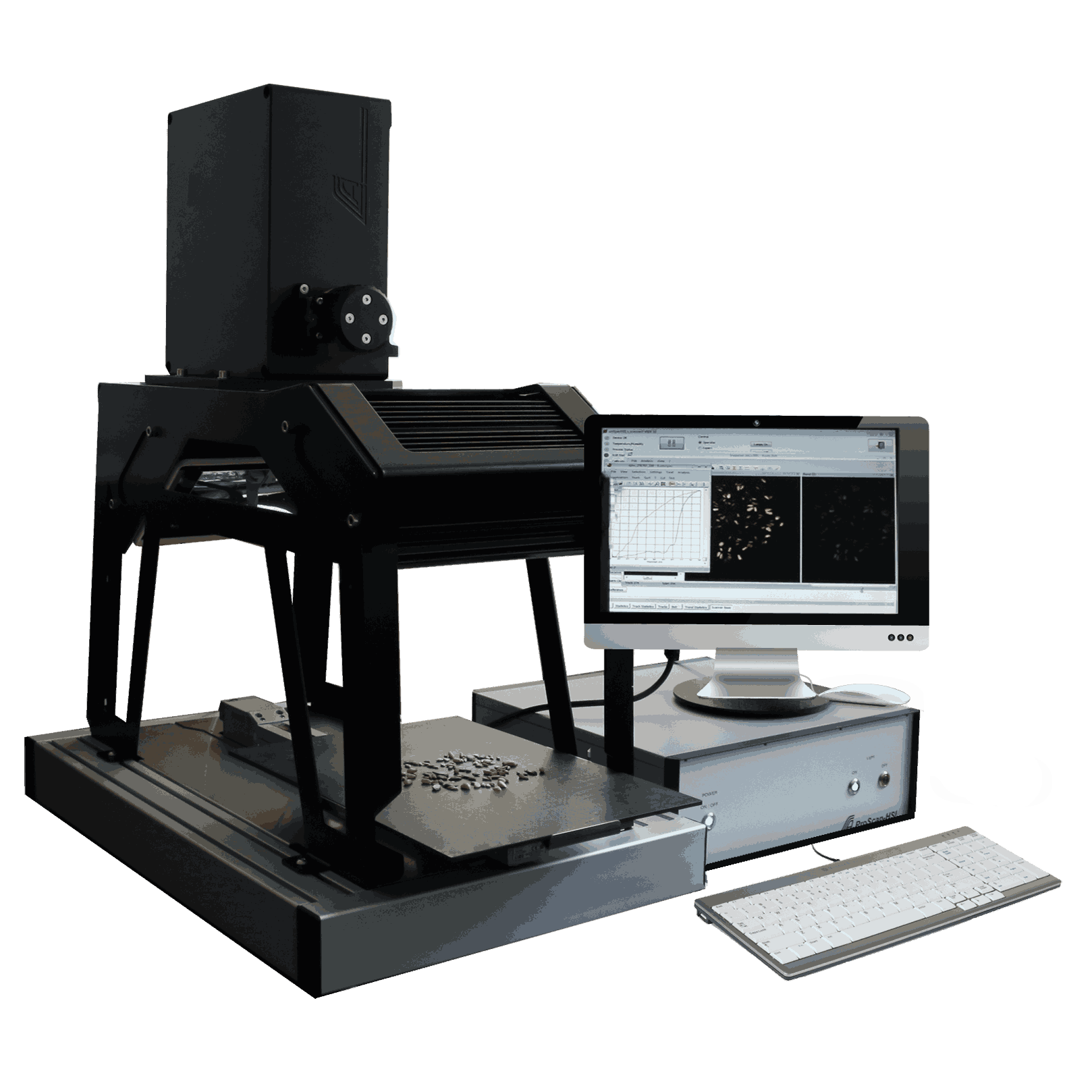

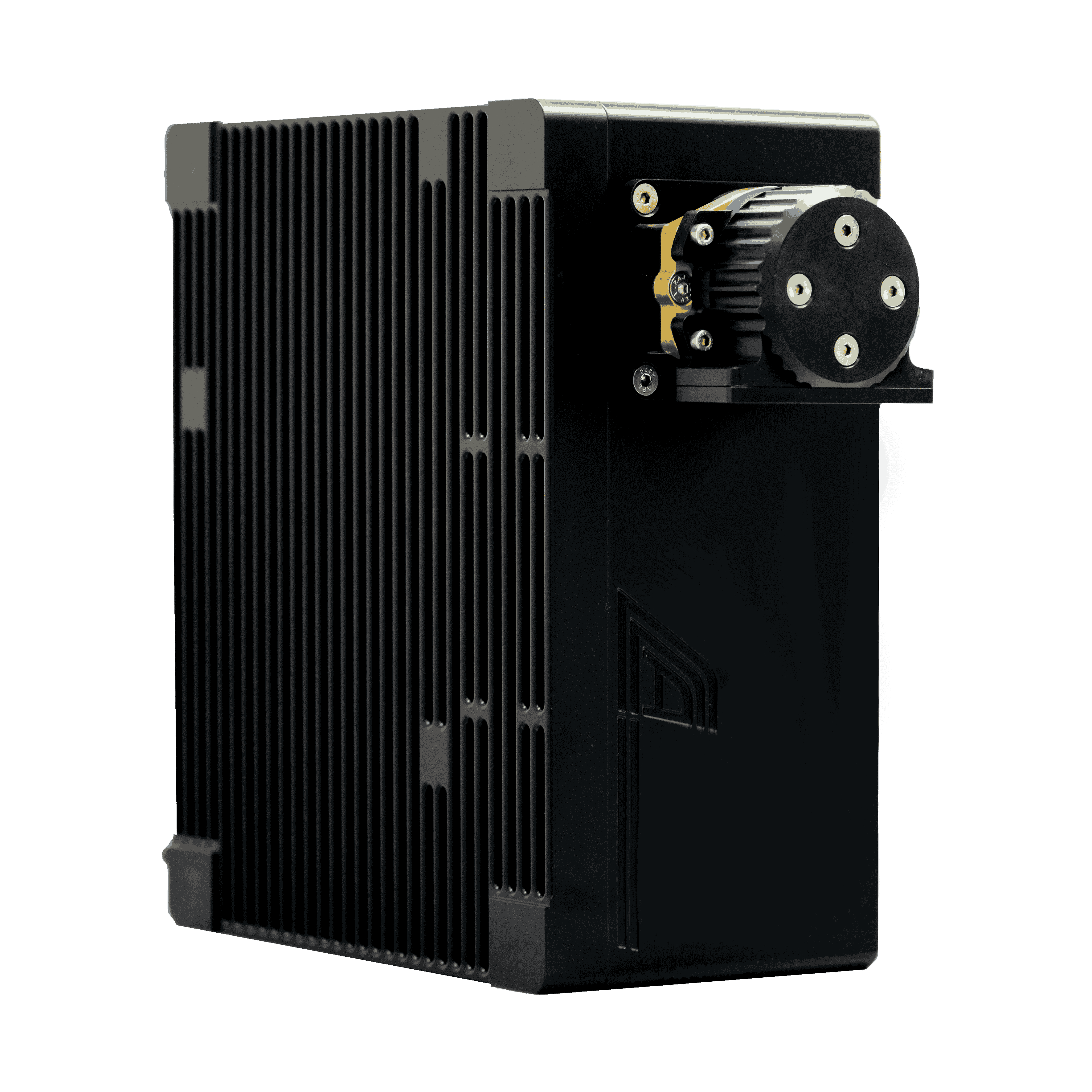

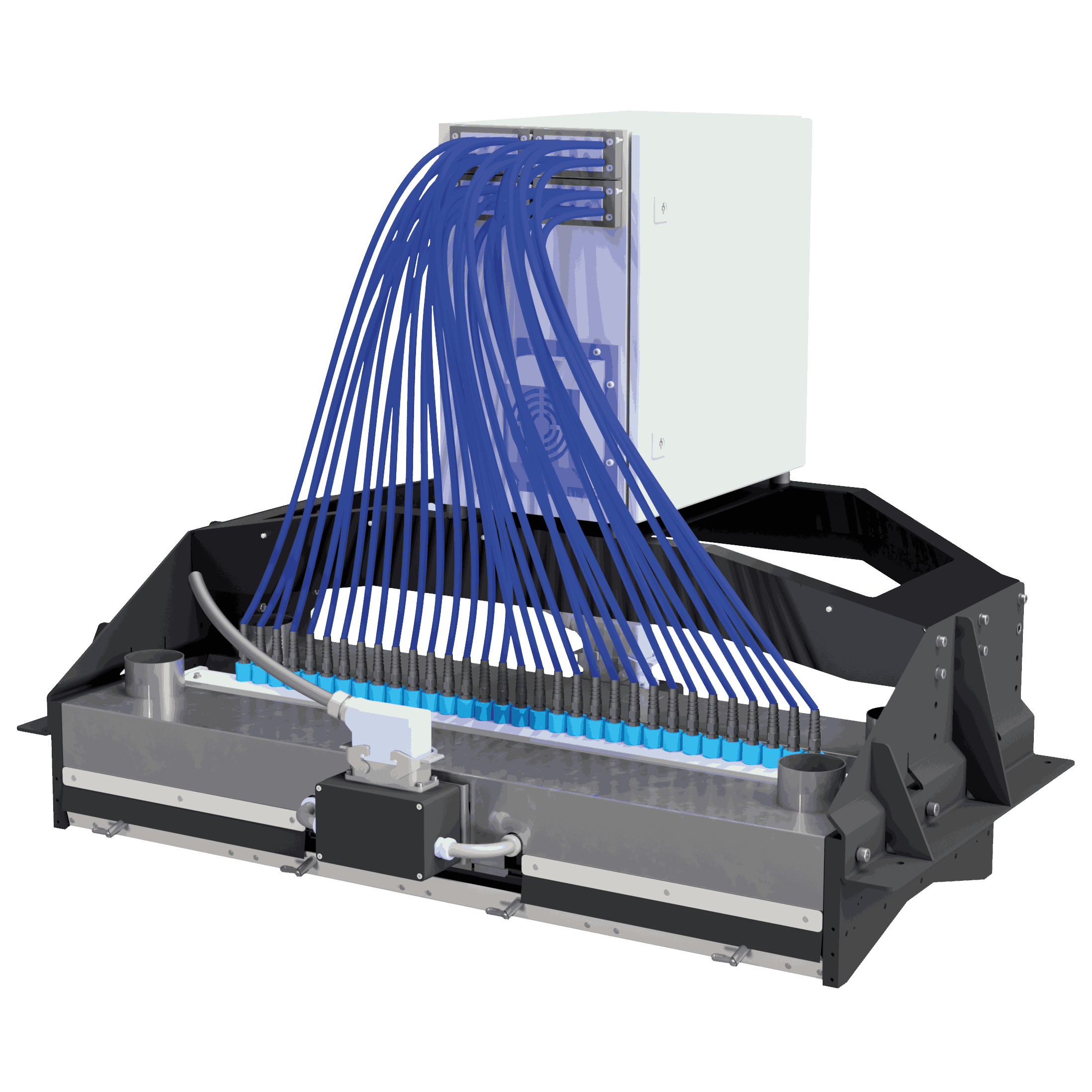

LLA’s XRF-line system is a high-performance X-ray fluorescence analyzer built for industrial metal sorting and analysis. It’s designed to deliver rapid, precise detection of metals and alloys—even on moving conveyor belts in rugged production environments.

Use cases include:

- Automated recycling and metal sorting

- Alloy verification in manufacturing

- Quality control and process monitoring

- Sorting of individual items (≥1 cm) and bulk materials

Because X-ray fluorescence is non-contact and non-destructive, it’s ideal for high-speed, high-volume workflows that demand precision.

Industrial Impact Meets Everyday Curiosity

While most people don’t use X-ray fluorescence to analyze antique gifts, this story highlights the versatility of the technology. Whether you’re a materials scientist, a production manager, or just a curious engineer, XRF analysis can reveal the hidden story behind any metal object.

Discover the Power of X-ray Fluorescence in Your Industry

LLA Instruments’ XRF-line system is used around the world for reliable, automated metal composition analysis. Our technology helps customers optimize workflows, ensure product quality, and unlock value from complex material streams.

Learn More

Ready to explore what X-ray fluorescence can do for your operations?

Discover the XRF-line system

Previous Post

Previous Post