X‑ray Fluorescence (XRF): The Proven Way to See Inside Your Ore

24 Apr 2025

Why Visual Inspection Falls Short

Relying on colour, luster, or density to identify minerals is risky. Weathering masks metal‑bearing phases and many gangue minerals imitate valuable ones. A misplaced bet on geology can mean wasted haulage, reagent overuse, or penalties at the smelter.

How X‑ray Fluorescence (XRF) Works

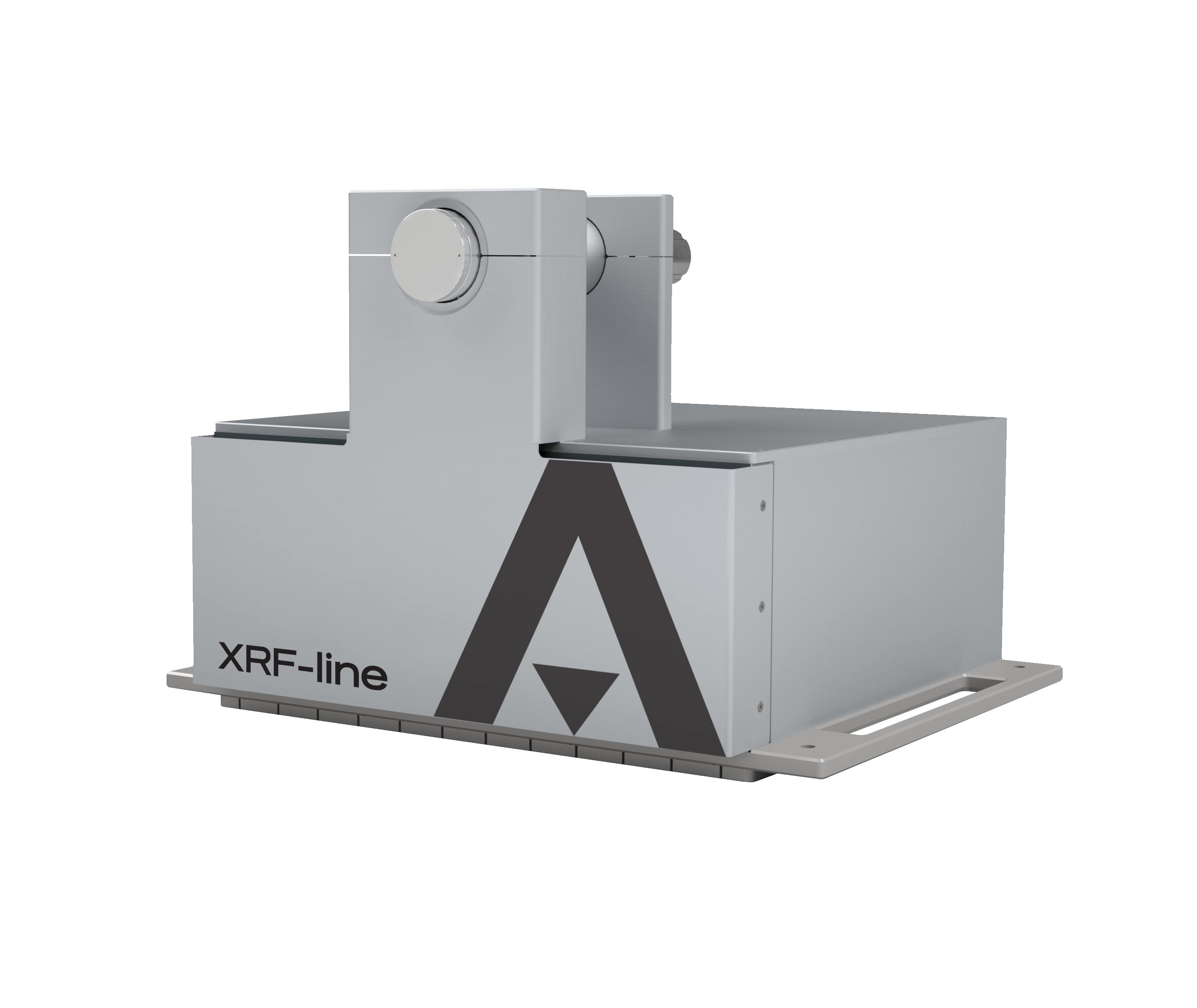

- Excitation – A primary X‑ray beam strikes the sample.

- Emission – Inner‑shell electrons are ejected; outer electrons fall inward, releasing element‑specific fluorescent photons.

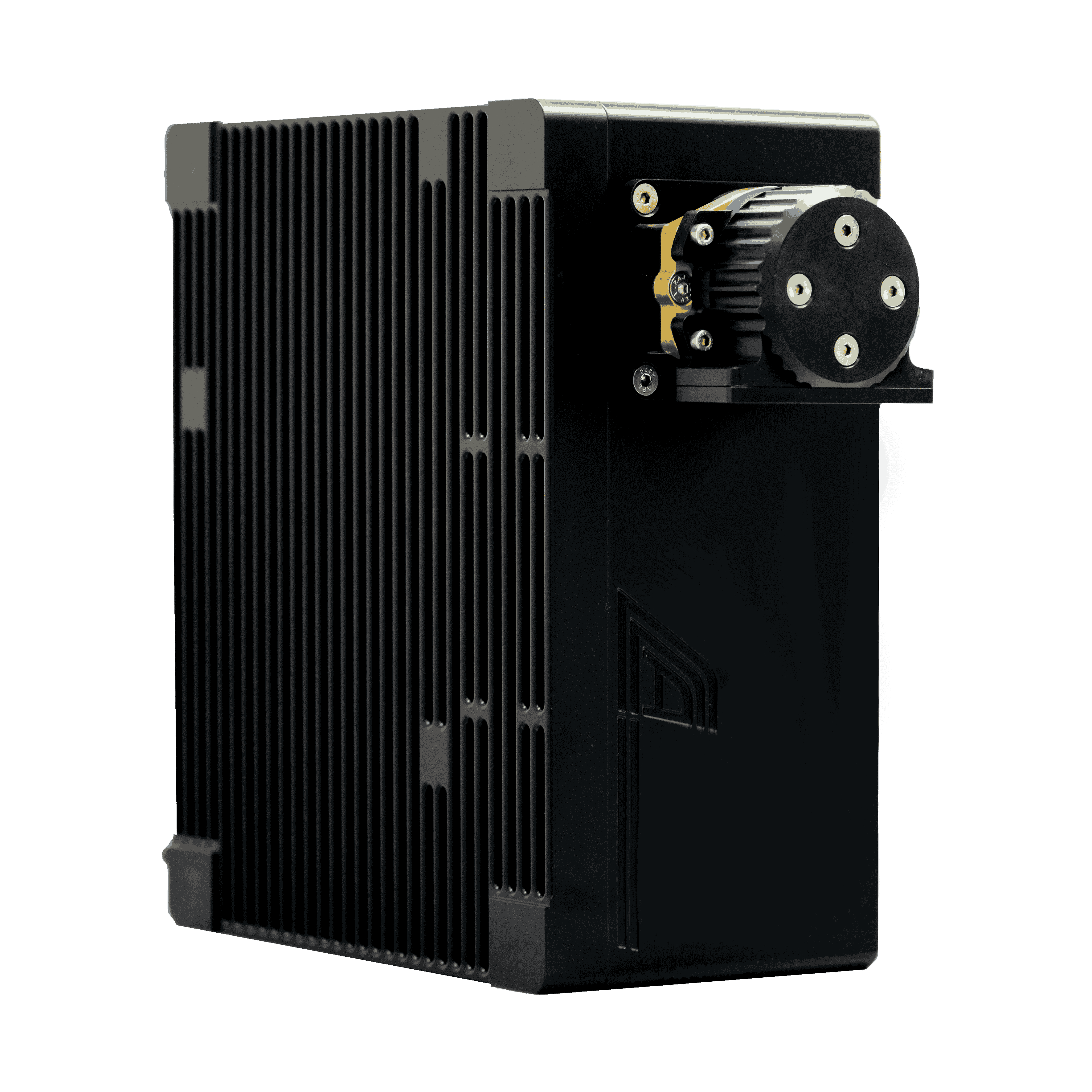

- Detection & Quantification – A silicon‑drift detector converts those photons into a spectrum. Calibrated software reports each element’s weight‑percent in seconds, without destroying the sample.

Because every element above sodium (Na) has a unique fluorescent signature, XRF spans everything from alumina to zinc—even trace levels.

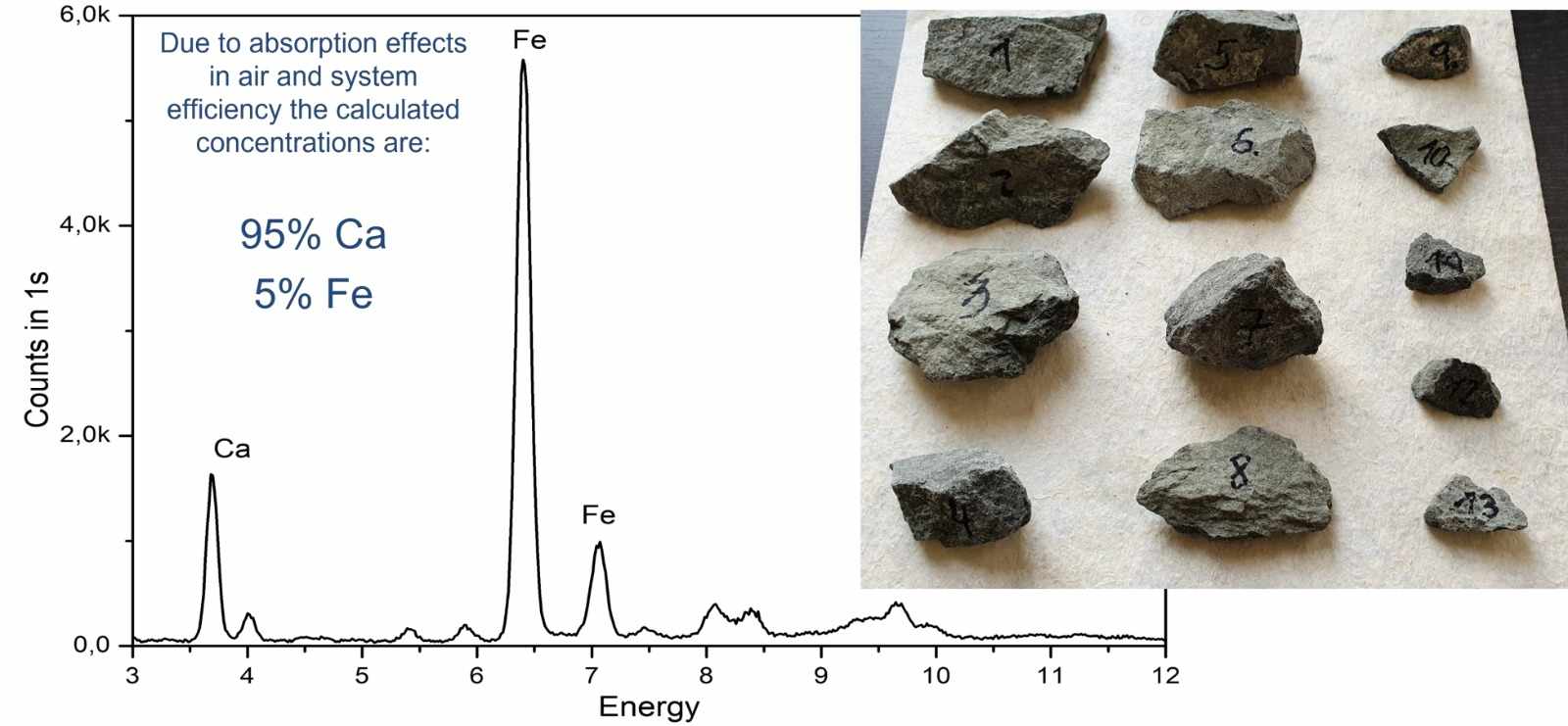

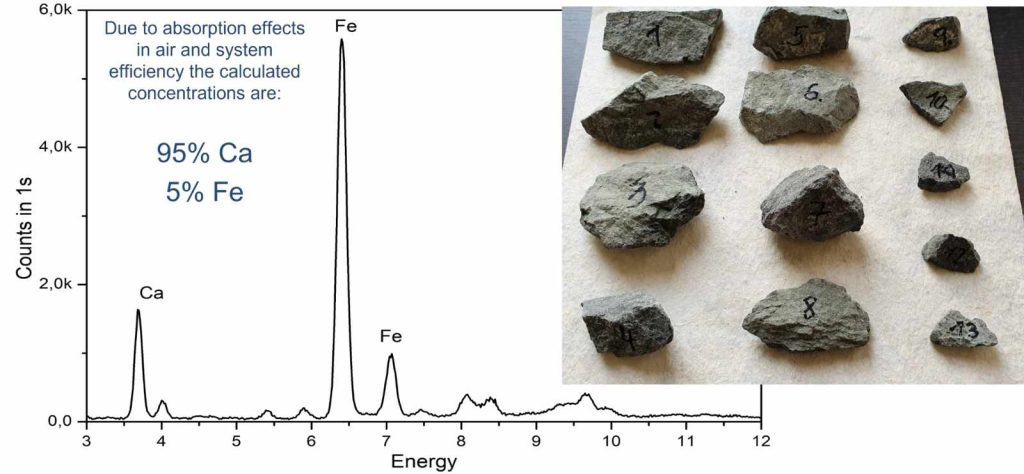

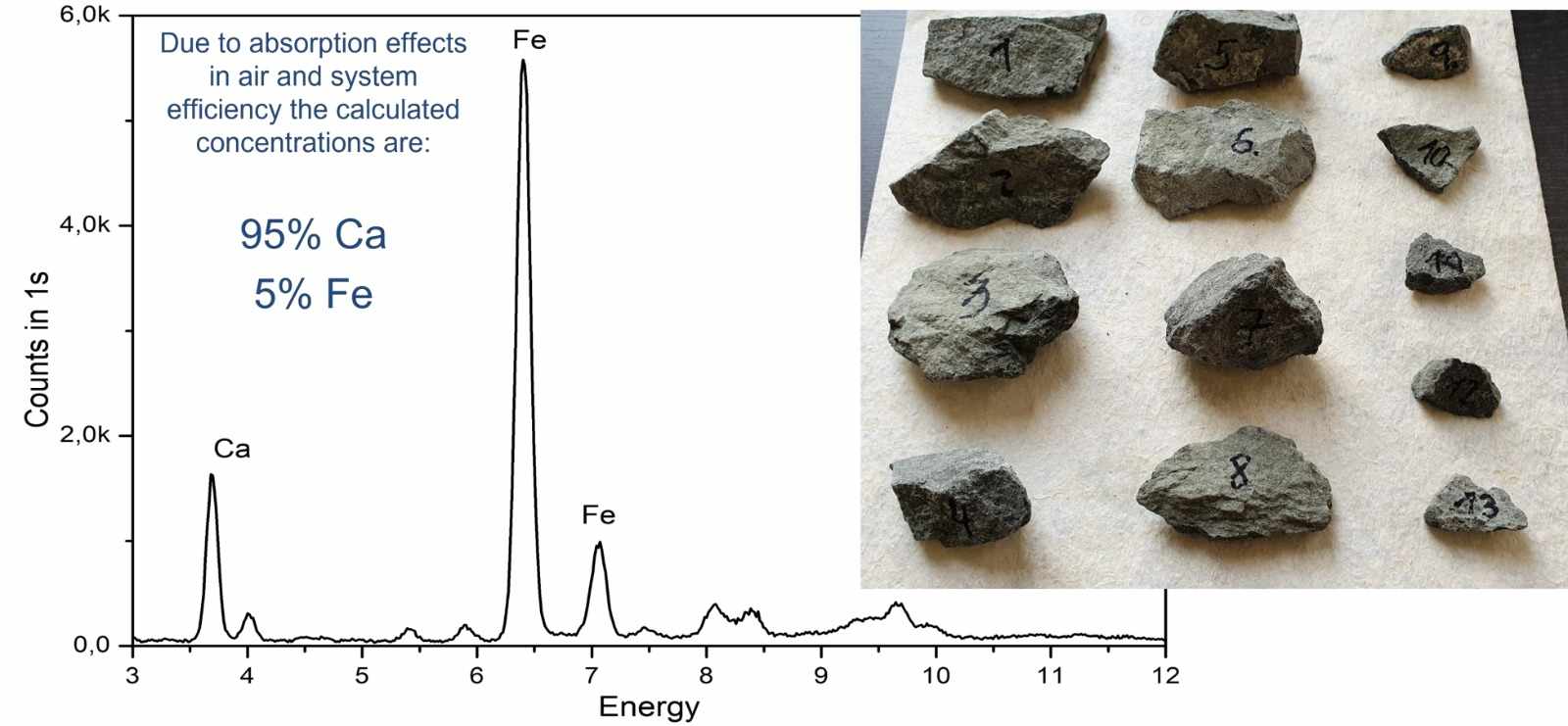

Case Study: Rapid Iron‑Ore Screening

| Element | Concentration (wt %) |

|---|---|

| Calcium | 95 % |

| Iron | 5 % |

A handheld XRF scan flagged this “iron‑rich” rock as mostly limestone, preventing unnecessary crushing and transport. Detecting iron at just five percent illustrates XRF’s sensitivity—crucial for:

- Grade control in open‑pit and underground mines

- Blend optimisation for sinter or pellet feed

- Early rejection of deleterious elements (e.g., P, S, As)

- Metallurgical accounting in hydromet and pyromet circuits

Benefits of XRF for Mining & Recycling Professionals

| Benefit | Impact on Operations |

|---|---|

| Real‑time data (1‑10 s) | Faster decisions, reduced downtime |

| Non‑destructive | Retain sample for further tests |

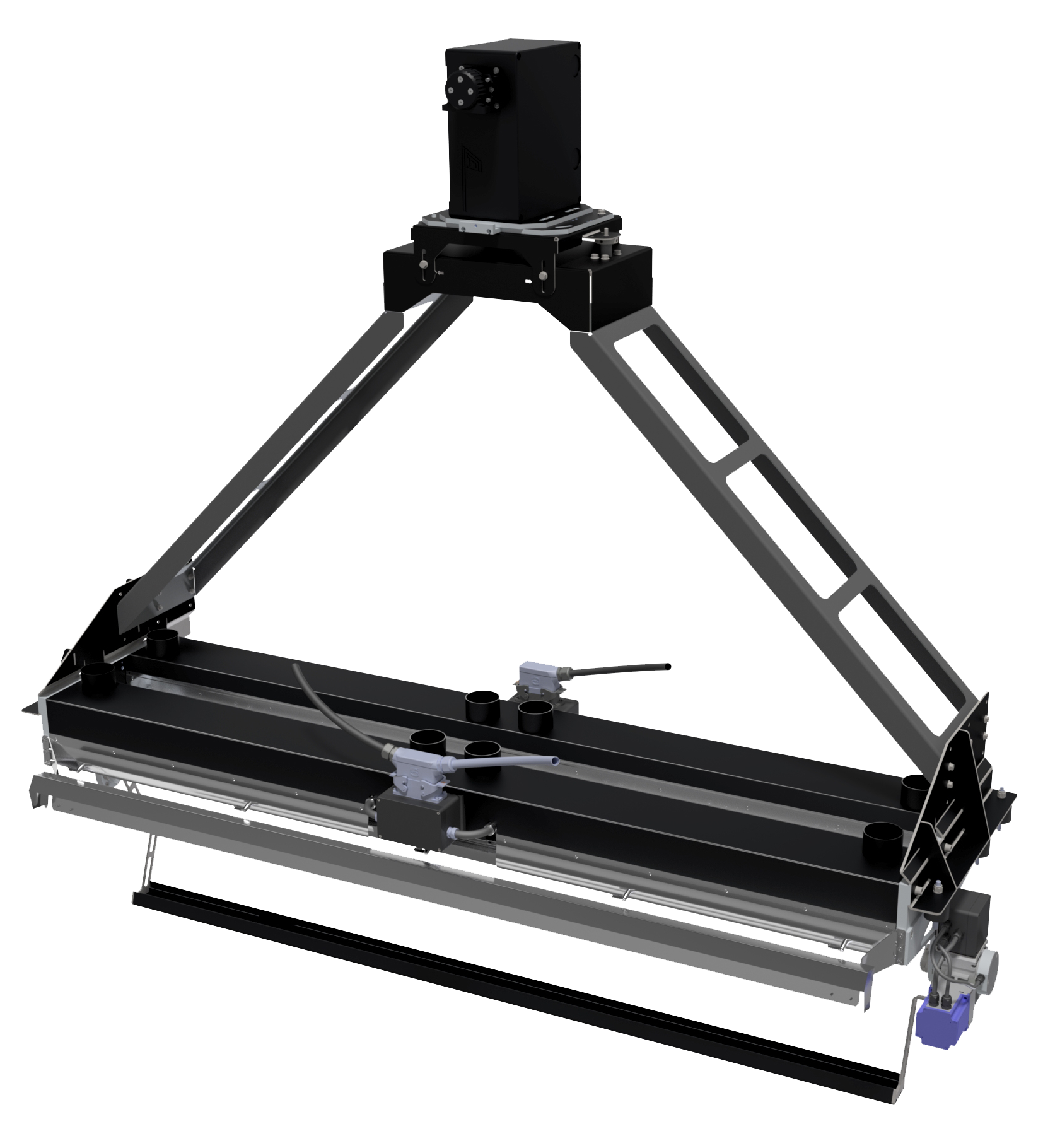

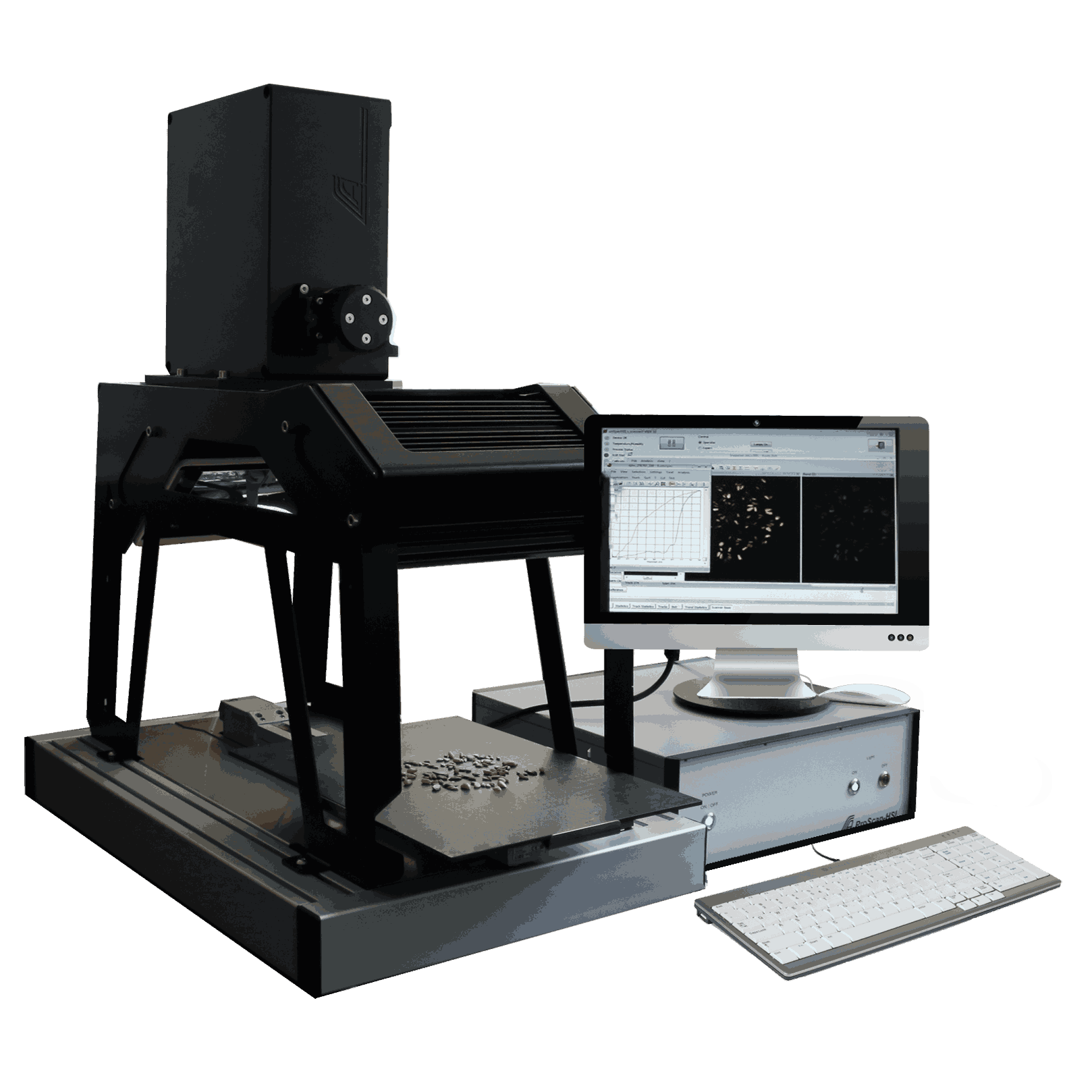

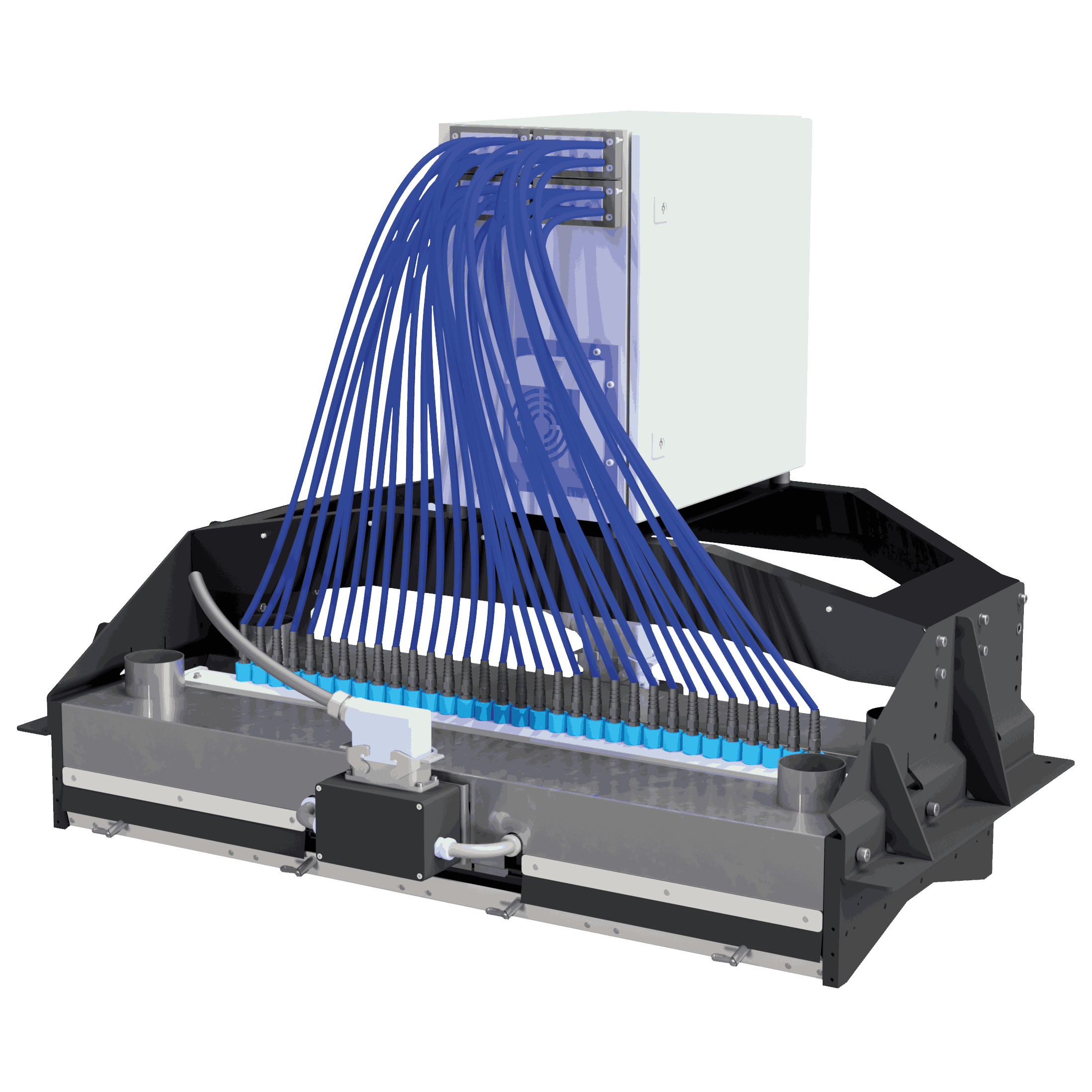

| Portable & in‑situ | Analyse core, muck piles, or conveyor streams |

| Low operating cost | No reagents, minimal consumables |

| Regulatory compliance | Demonstrate due diligence for ISO 17025 & ESG audits |

Ready to Optimise Your Ore or Scrap Stream?

📧 application@lla.de | ☎️ +49 (0)30 4091‑2840

Schedule a free consultation. Discover how X‑ray fluorescence can unlock hidden value and ensure process reliability—from exploration to final assay.

Previous Post

Previous Post