Wavelength ranges: VIS, NIR, SWIR

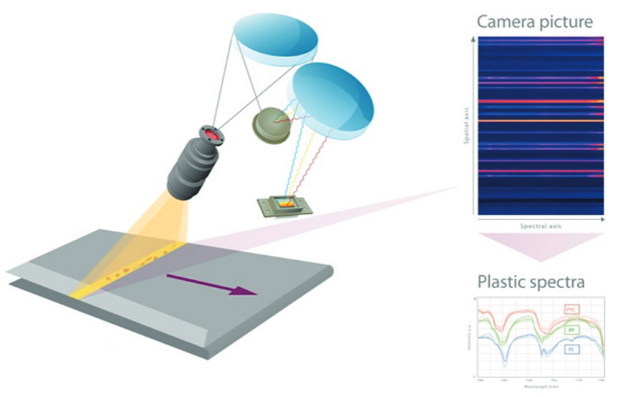

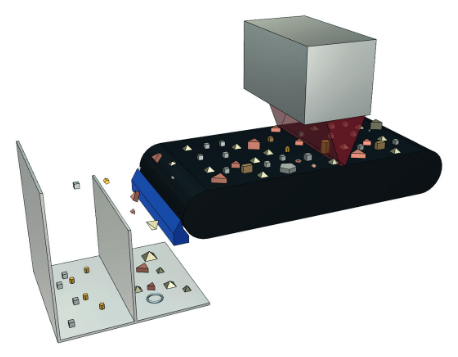

A strip in the camera’s field of view is illuminated and an imaging spectrograph produces sequentially high-resolution spectral and spatial images through its sensors. This technique is also known as push-broom technology. Figure 1 illustrates how it works.

How it works

Technical points

Due to their significant effect on performance, some technical points are worth mentioning:

Short focal length, corrected NIR lenses:

large field of view

ZEISS optics & Offner spectrograph:

high-quality spectra

High-performance image sensor:

Optimised electronics

measurement of extremely fast objects, high throughput

Figure 1: Principle of the Offner setup and data processing

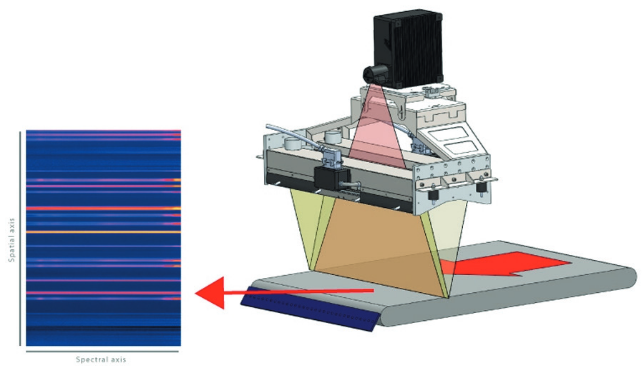

Figure 2: Principle of our camera in operation

Hyperspectral cameras

Wavelength ranges: VIS/NIR/SWIR

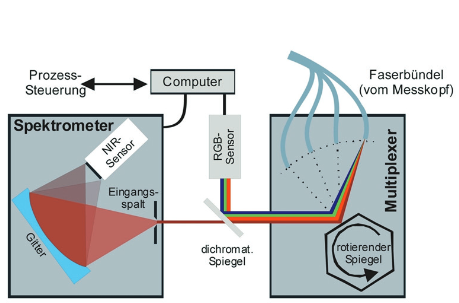

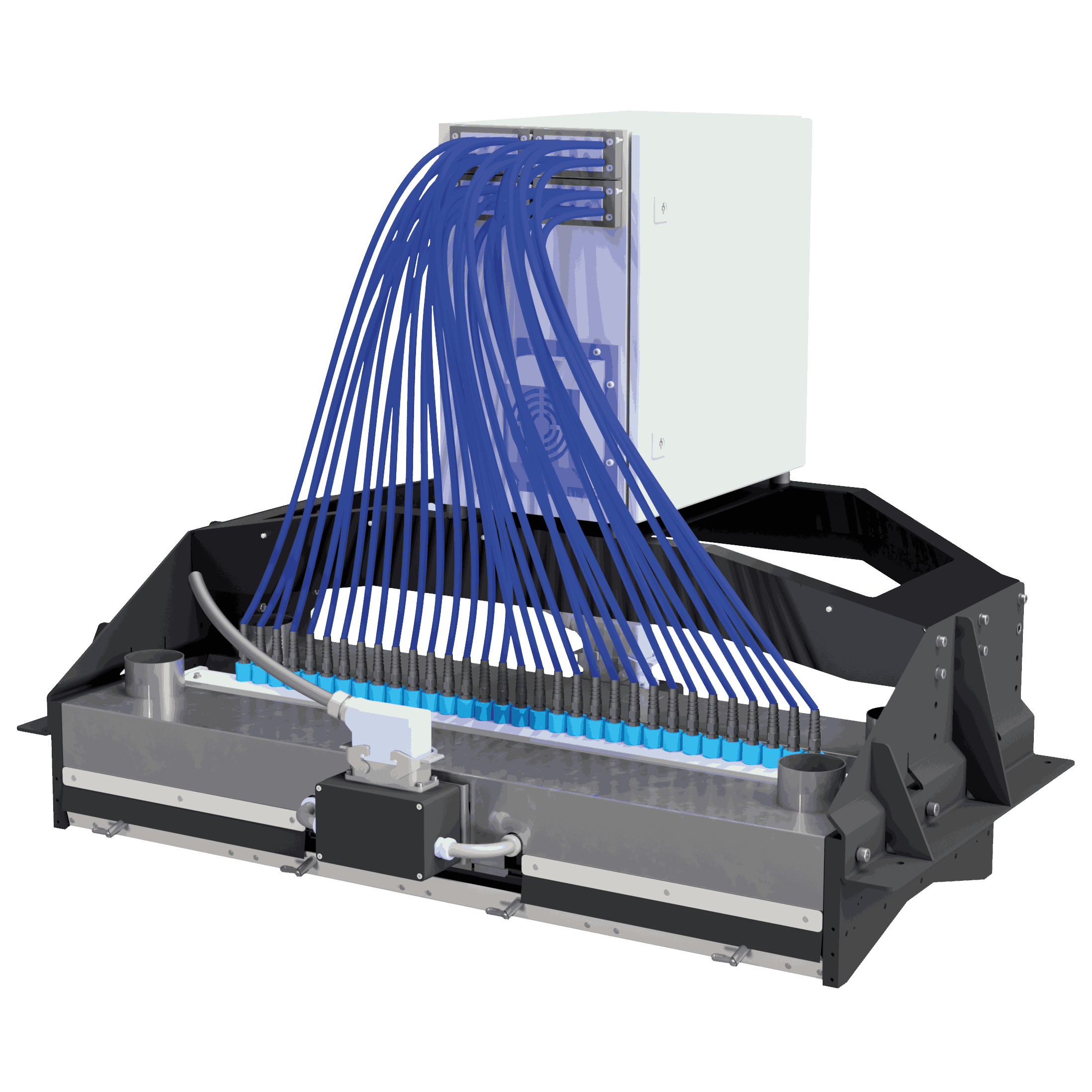

A strip in the camera’s field of view is illuminated and sequentially imaged onto optical fibres arranged in a row. This technique is called push-broom technology. Figure 1 illustrates how it works.

How it works

Technical points

Independent optical fibres:

simultaneous measurement on multiple conveyors

ZEISS optics:

Figure 1: Beam path in multiplexer

Multiplexed NIR Spectrometer

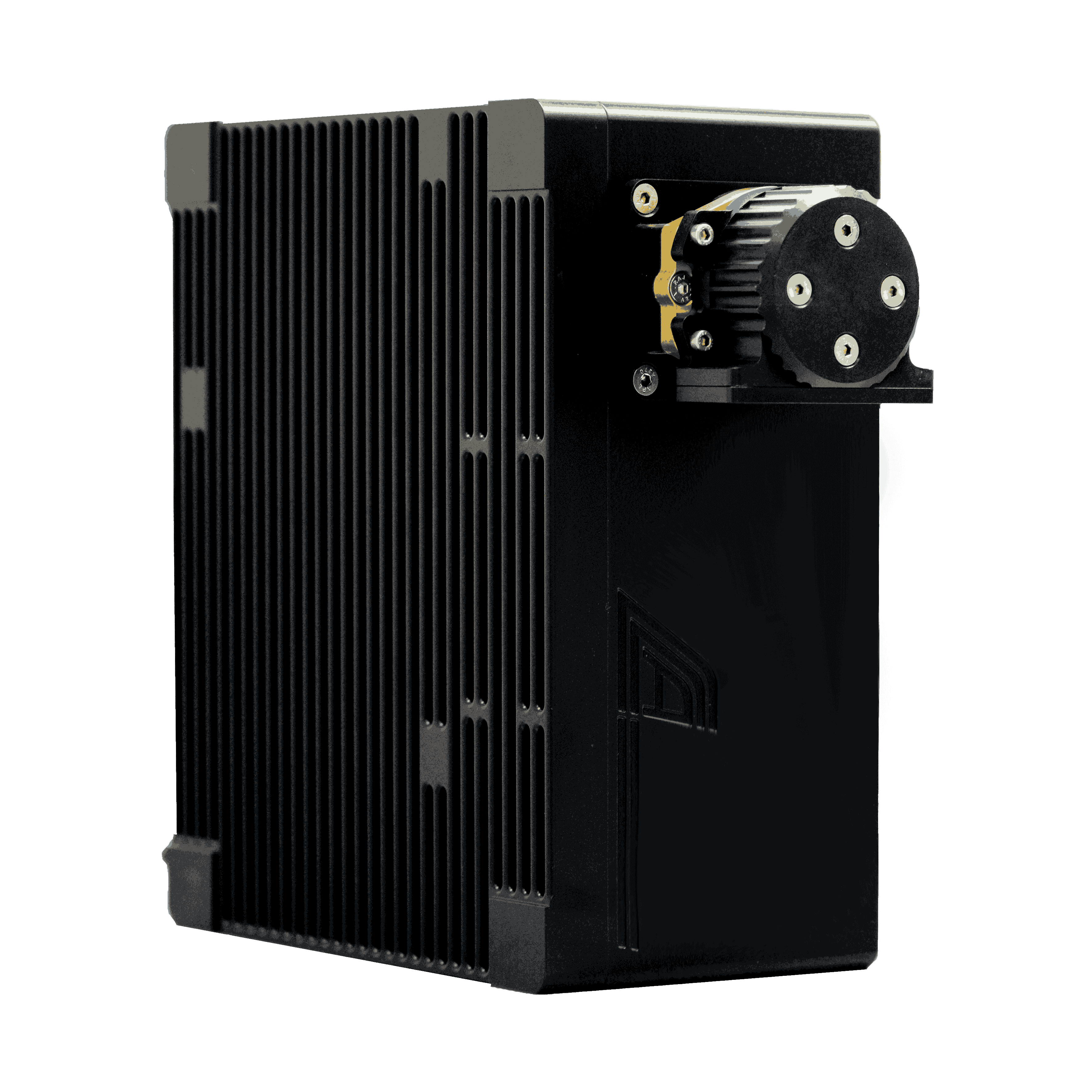

Wavelength ranges: VIS

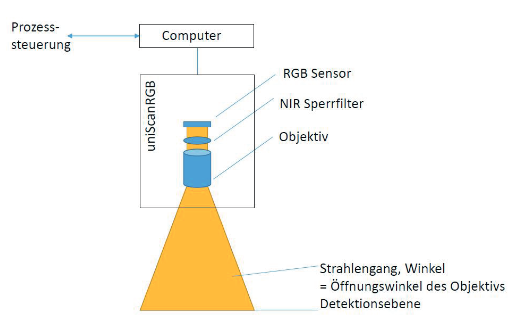

A strip in the camera’s field of view is illuminated and sequentially measured at a high frame rate. This technique is called push-broom technology. The beam path is shown in Figure 1 to illustrate how it works.

How it works

Technical points

Optimised electronics:

measurement of extremely fast objects, high throughput

CMOS sensor & ZEISS optics:

high image contrast, low noise

Universal line scan colour camera

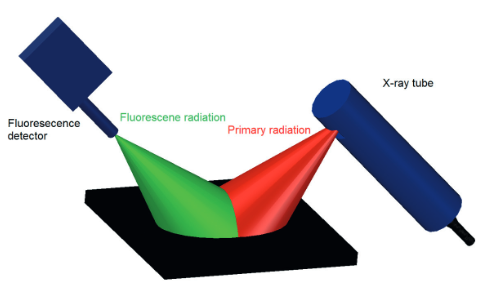

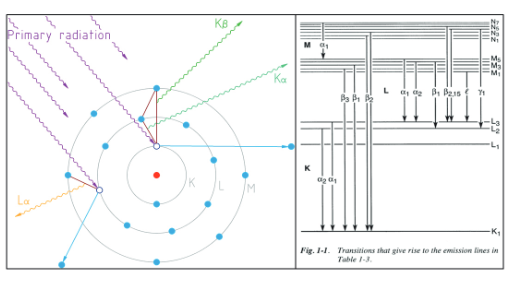

Wavelength ranges: X-ray/UV

A strip in the detector’s field of view is illuminated and sequentially measured. This technique is also known as push-broom technology.

How it works

Technical points

Water-cooled, high power x-ray tube:

high primary radiation intensity produces high fluorescence radiation intensity

Silicon drift detectors or the latest generation:

high count rates and best-possible energy resolution

Complete system (tube, detector & electronics:

fast and detailed identification of alloys, not only the main elements

Figure 1: Functionality of x-ray fluorescence analysis

X-ray fluorescence analyser

LLA Instruments GmbH

Justus-von-Liebig Straße 9/11

12489 Berlin

Germany

Justus-von-Liebig

Straße 9/11

12489 Berlin

Germany