Hyperspectral Cameras: A Practical Guide for Industrial Applications

18 Dec 2025

A hyperspectral camera is an advanced imaging system that captures detailed spectral information for every pixel in an image. Unlike conventional cameras that record only colour or intensity, hyperspectral cameras analyse the material composition of objects, enabling precise identification, classification, and sorting. In industrial environments—such as recycling, material processing, and quality control—hyperspectral cameras have become a key technology for real-time material analysis.

What Is a Hyperspectral Camera?

A hyperspectral camera records an image across dozens or hundreds of narrow wavelength bands. Each pixel contains a full spectral signature, which allows materials to be identified based on their unique interaction with light.

This makes hyperspectral cameras fundamentally different from:

- RGB cameras (colour only)

- Multispectral cameras (limited number of bands)

Key advantage:

Material identification, not just visual appearance

How Does a Hyperspectral Camera Work?

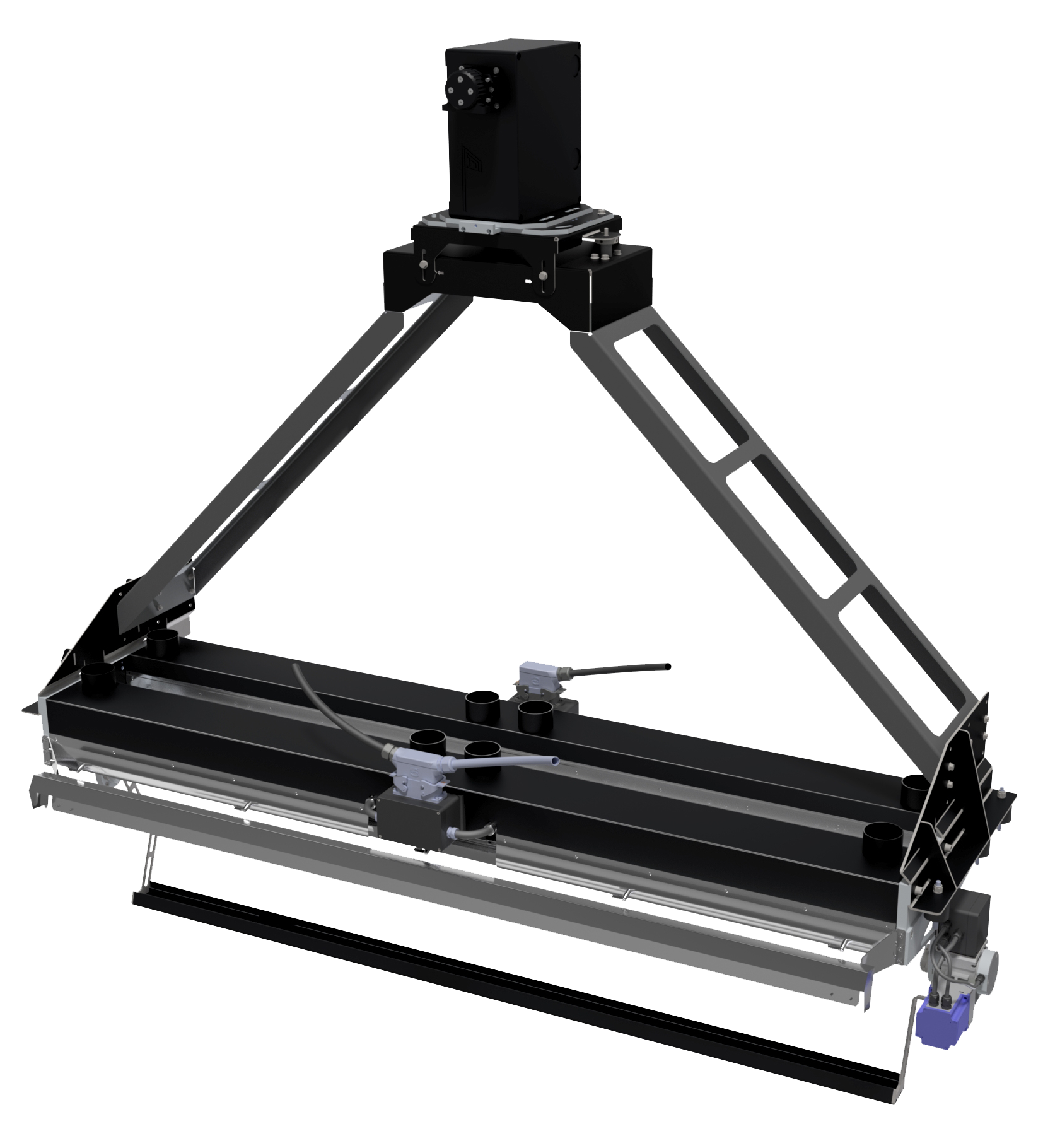

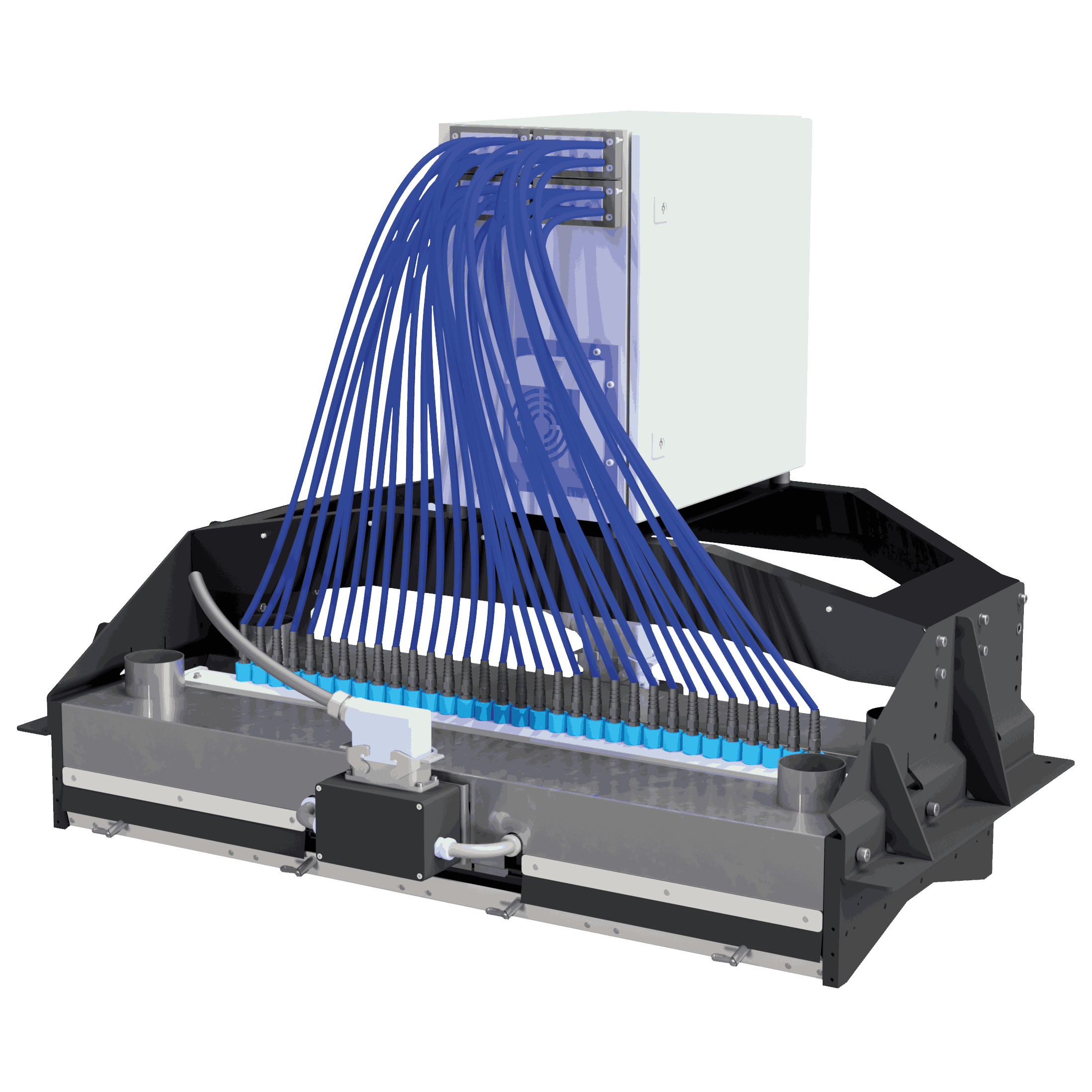

Most industrial hyperspectral cameras use a push-broom (line-scan) principle:

- Material moves on a conveyor belt

- The camera captures one line at a time

- Each line contains spatial and spectral information

- Software analyses spectra in near real time

This approach is ideal for:

- High material throughput

- Continuous production processes

- Optical sorting systems

Spectral Ranges Explained: VIS, NIR and SWIR

Different hyperspectral cameras operate in different wavelength ranges, depending on the application.

VIS (Visible Light, ~0.35–0.75 µm)

- Colour analysis

- Surface features

- Fluorescence detection

NIR (Near Infrared, ~0.75–1.0 µm)

- Plastic identification

- Organic vs inorganic materials

- Moisture detection

SWIR (Short-Wave Infrared, ~1.0–2.5 µm)

- Polymer differentiation

- Paper, textiles, wood

- Food and agricultural analysis

Industrial hyperspectral cameras often focus on NIR and SWIR, where material-specific absorption features are strongest.

Why Hyperspectral Cameras Are Essential for Recycling and Sorting

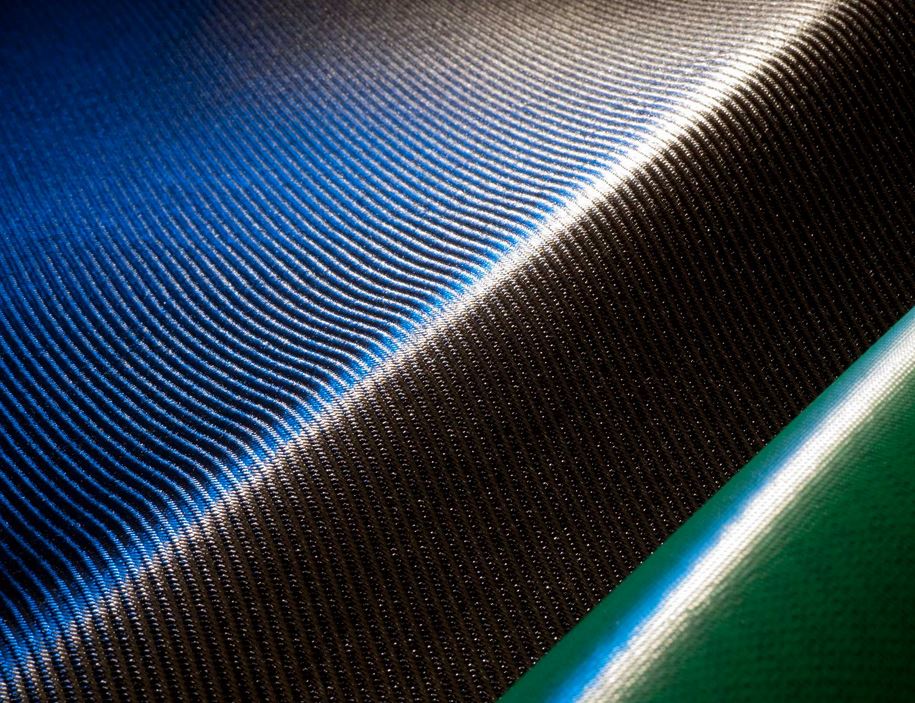

In recycling plants, materials often look identical to the human eye but differ chemically. Hyperspectral cameras enable:

- Identification of different plastic types

- Separation of paper grades

- Detection of contaminants

- Real-time control of sorting systems

Because the analysis is non-contact and fast, hyperspectral cameras can be integrated directly into high-speed sorting lines.

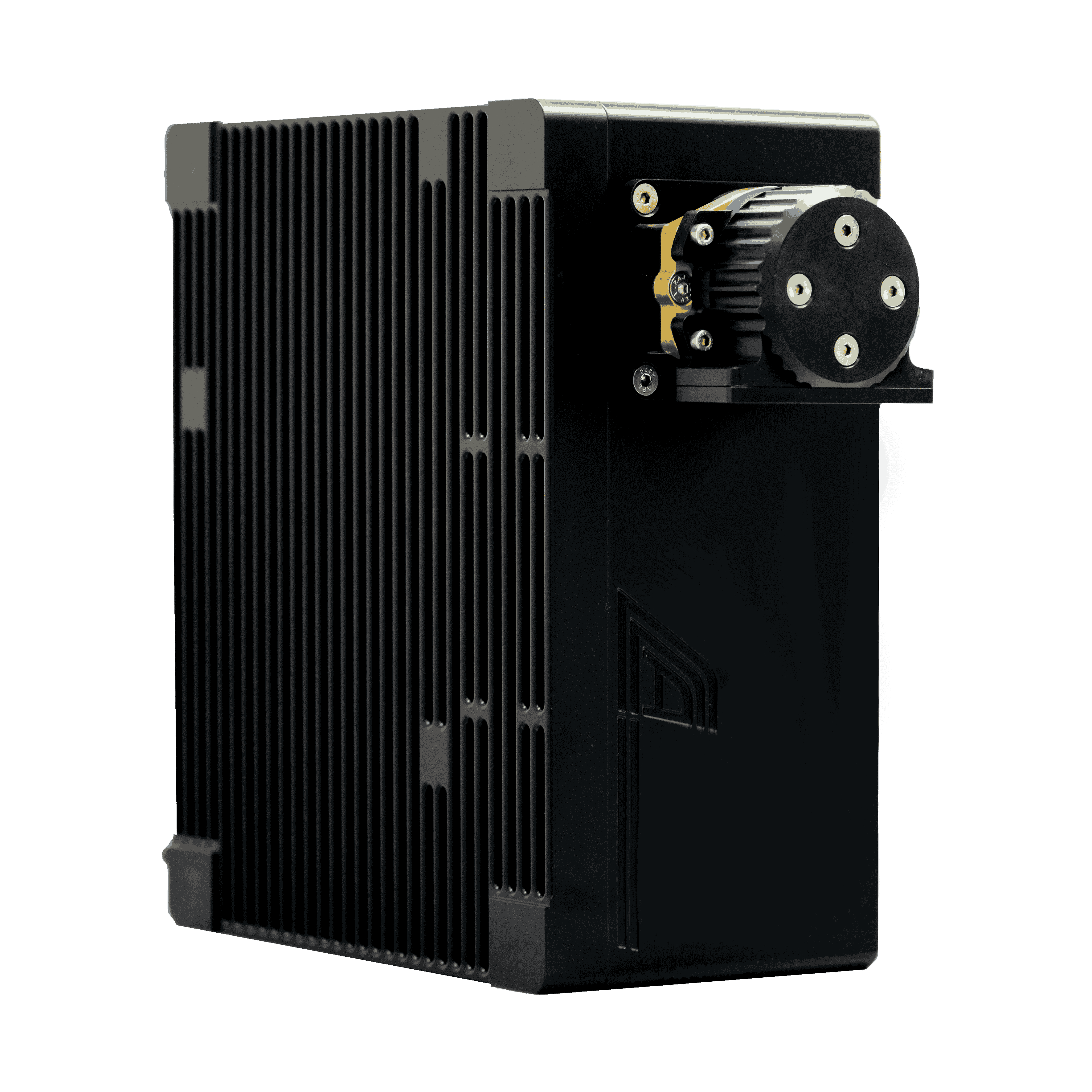

Key Features of Industrial Hyperspectral Cameras

When selecting a hyperspectral camera for industrial use, important characteristics include:

- High spectral resolution for accurate material discrimination

- High frame rates for fast conveyors

- Distortion-free optics (no smile or keystone effects)

- Robust housing (IP-rated) for harsh environments

- Industrial interfaces (GigE, GenICam)

- Real-time software and automation compatibility

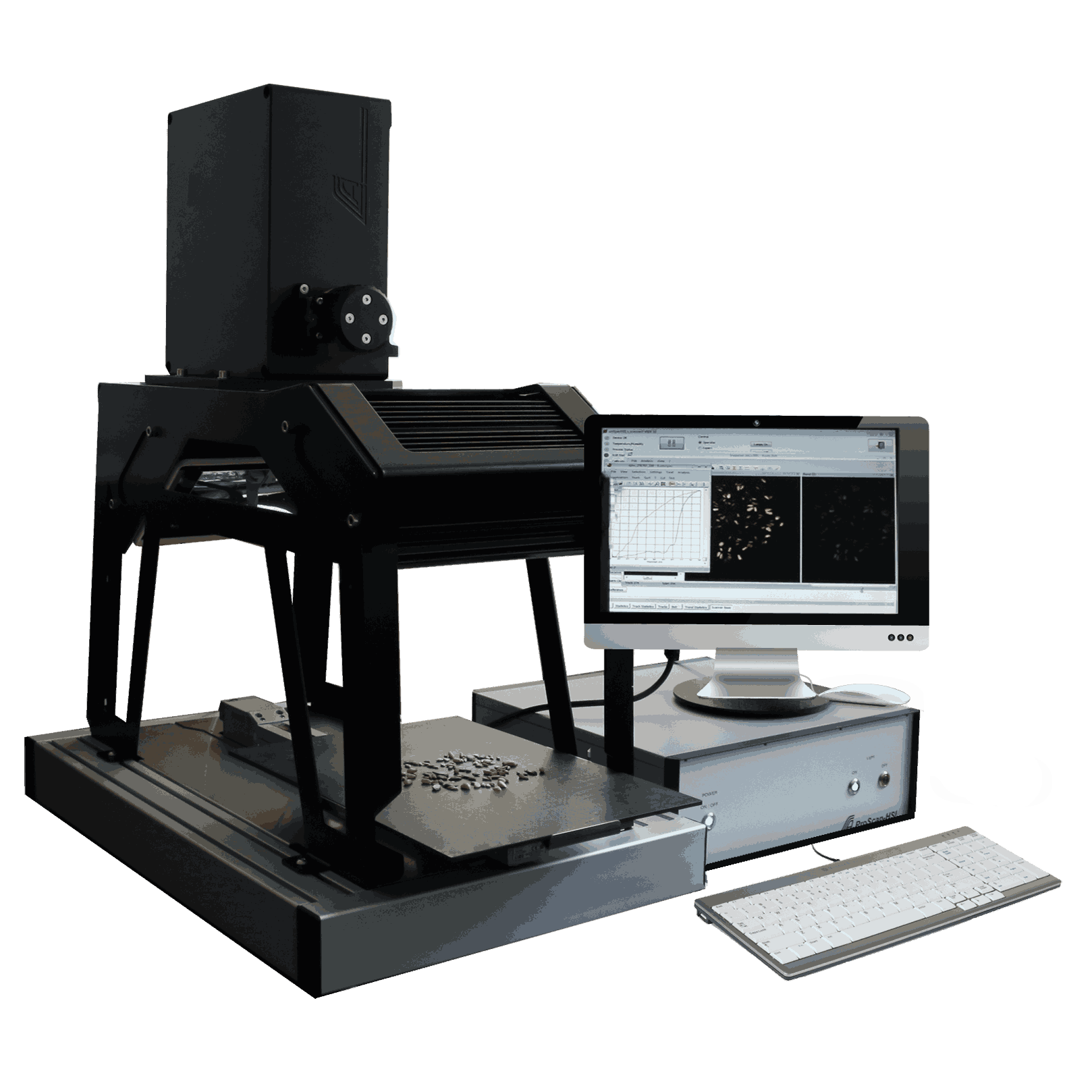

Hyperspectral Cameras vs Laboratory Systems

Many hyperspectral cameras are designed for laboratories or research. Industrial hyperspectral cameras differ by offering:

- Continuous 24/7 operation

- Integration into machine vision systems

- Automated decision-making

- On-line analysis instead of offline post-processing

This distinction is crucial for machine builders and system integrators.

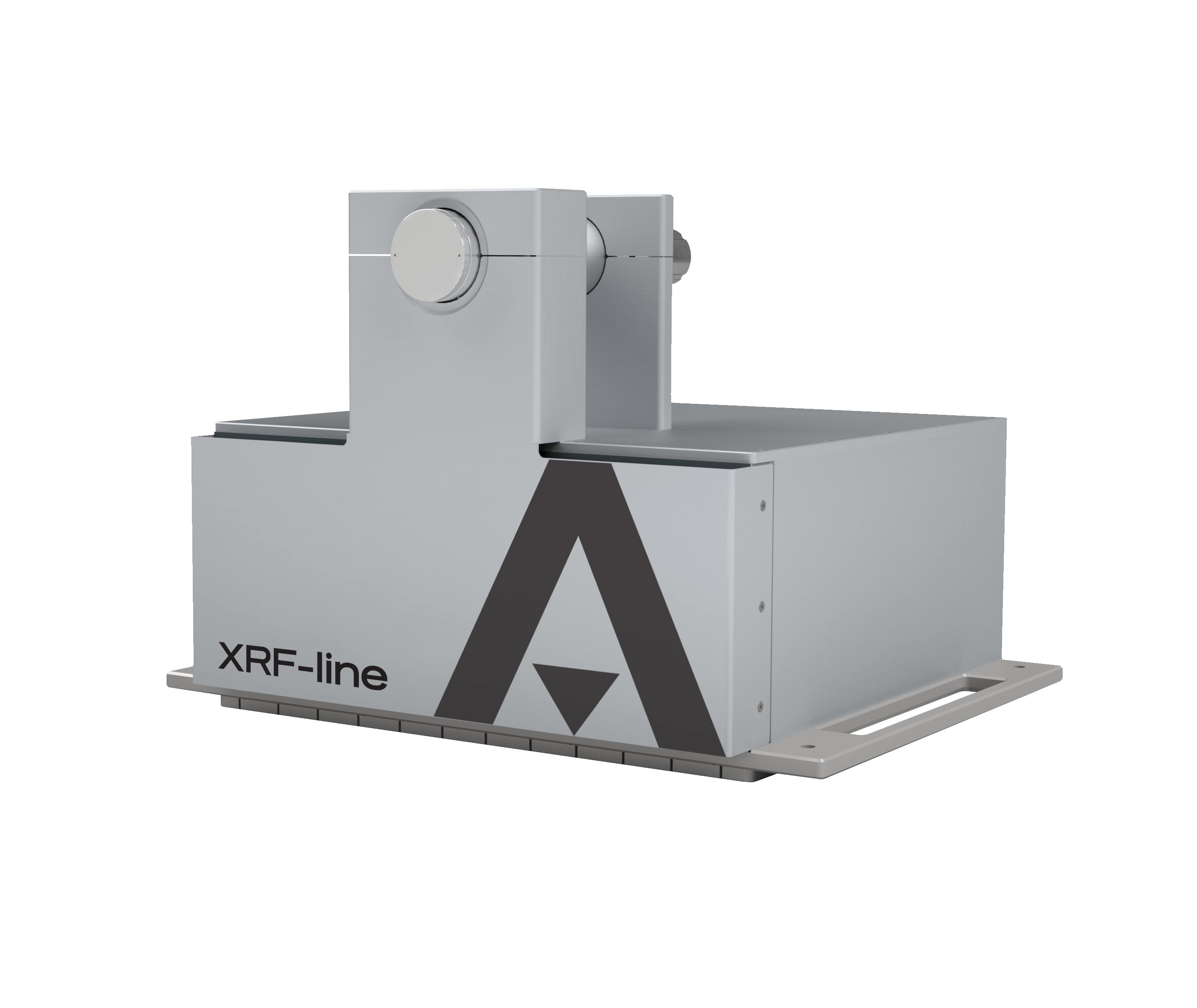

Hyperspectral Cameras for Machine Builders

Machine builders benefit from hyperspectral cameras that:

- Provide stable, calibrated data

- Offer standardised interfaces

- Support AI and machine vision frameworks

- Can be delivered as complete system solutions

For this reason, industrial suppliers often deliver hyperspectral camera systems, including illumination, software, and industrial PCs.

Conclusion: Choosing the Right Hyperspectral Camera

A hyperspectral camera is more than an imaging device—it is a material analysis tool. Selecting the right system depends on:

- Required spectral range (VIS, NIR, SWIR)

- Conveyor width and speed

- Target materials

- Integration into existing automation systems

In industrial sorting and recycling, hyperspectral cameras enable reliable, real-time decisions that are impossible with conventional imaging technologies.

Previous Post

Previous Post