How Machine Builders Integrate Hyperspectral Cameras into Sorting Machines

18 Dec 2025

Industrial sorting machines are becoming increasingly advanced, driven by the demand for higher accuracy, faster throughput, and automation in recycling and manufacturing processes. A critical technology powering this transformation is hyperspectral imaging. For machine builders and OEMs, integrating hyperspectral cameras into sorting machines requires careful planning, precise engineering, and a deep understanding of both hardware and software requirements.

In this guide, we explain how machine builders successfully integrate hyperspectral cameras into their systems, the best practices for achieving high performance, and the common challenges to avoid.

What Are Hyperspectral Cameras?

Hyperspectral cameras capture images across multiple wavelengths of light, far beyond the visible spectrum (VIS). These cameras often operate in NIR (Near-Infrared) or SWIR (Short-Wave Infrared) ranges, allowing detection of chemical composition, moisture content, and material type.

For sorting applications, hyperspectral cameras are ideal for:

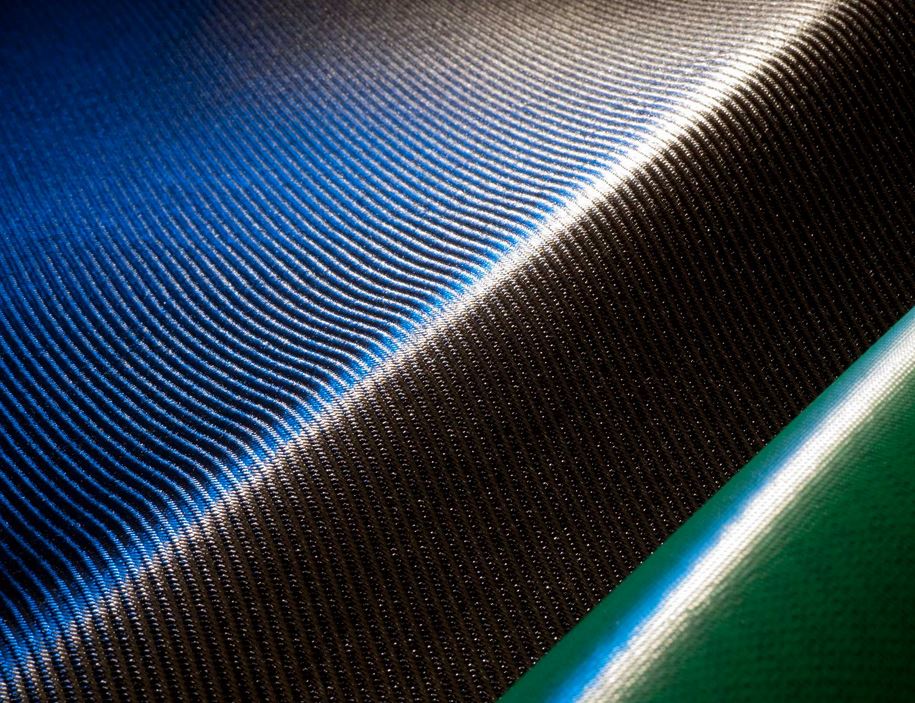

- Plastic identification (PVC, PET, PA, etc.)

- Metal and alloy sorting

- Textile and paper classification

- Process monitoring and quality assurance

By integrating these cameras, machine builders enable real-time, non-contact material analysis on conveyor belts and production lines.

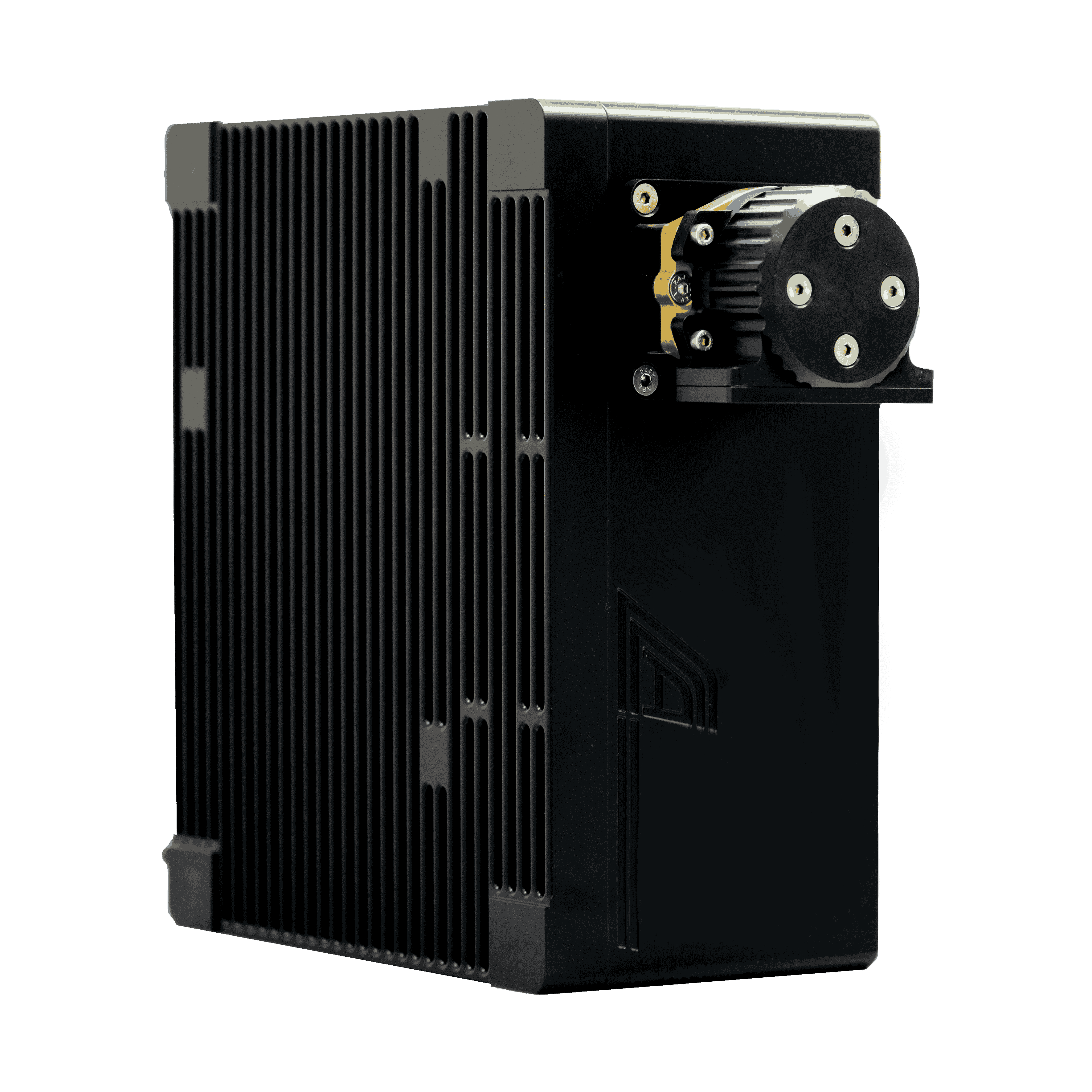

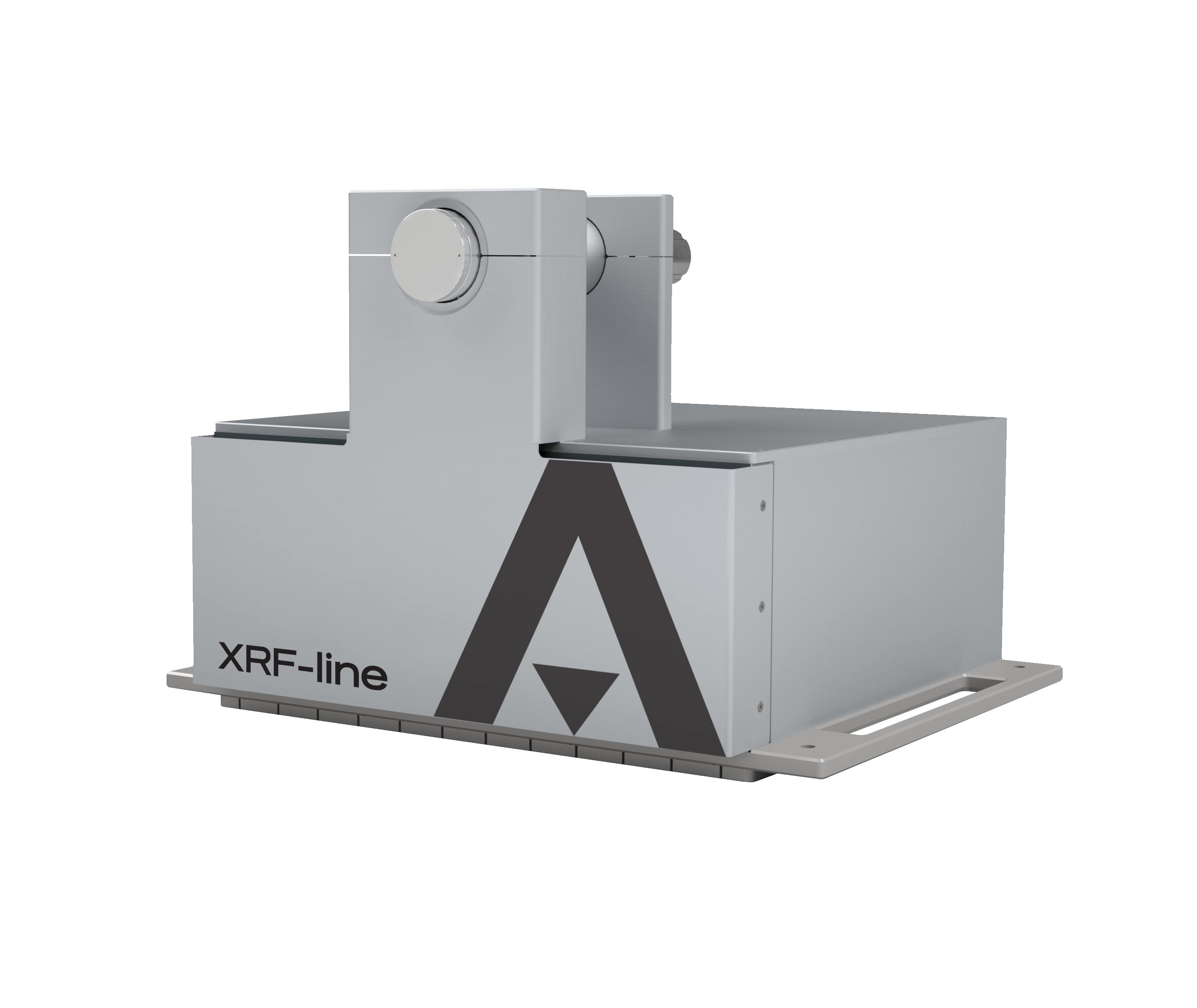

Step 1: Choosing the Right Hyperspectral Camera

Selecting the right hyperspectral camera depends on:

- Spectral Range: VIS (0.35–0.95 μm), NIR (0.95–1.7 μm), SWIR (1.03–2.2 μm)

- Frame Rate: High-speed cameras can capture moving materials at 500–800 Hz

- Spatial Resolution: Determines the level of detail for object detection

- Robustness: IP-rated, dust-proof, and temperature-tolerant designs

Machine builders must match camera specifications to material type, conveyor speed, and sorting goals.

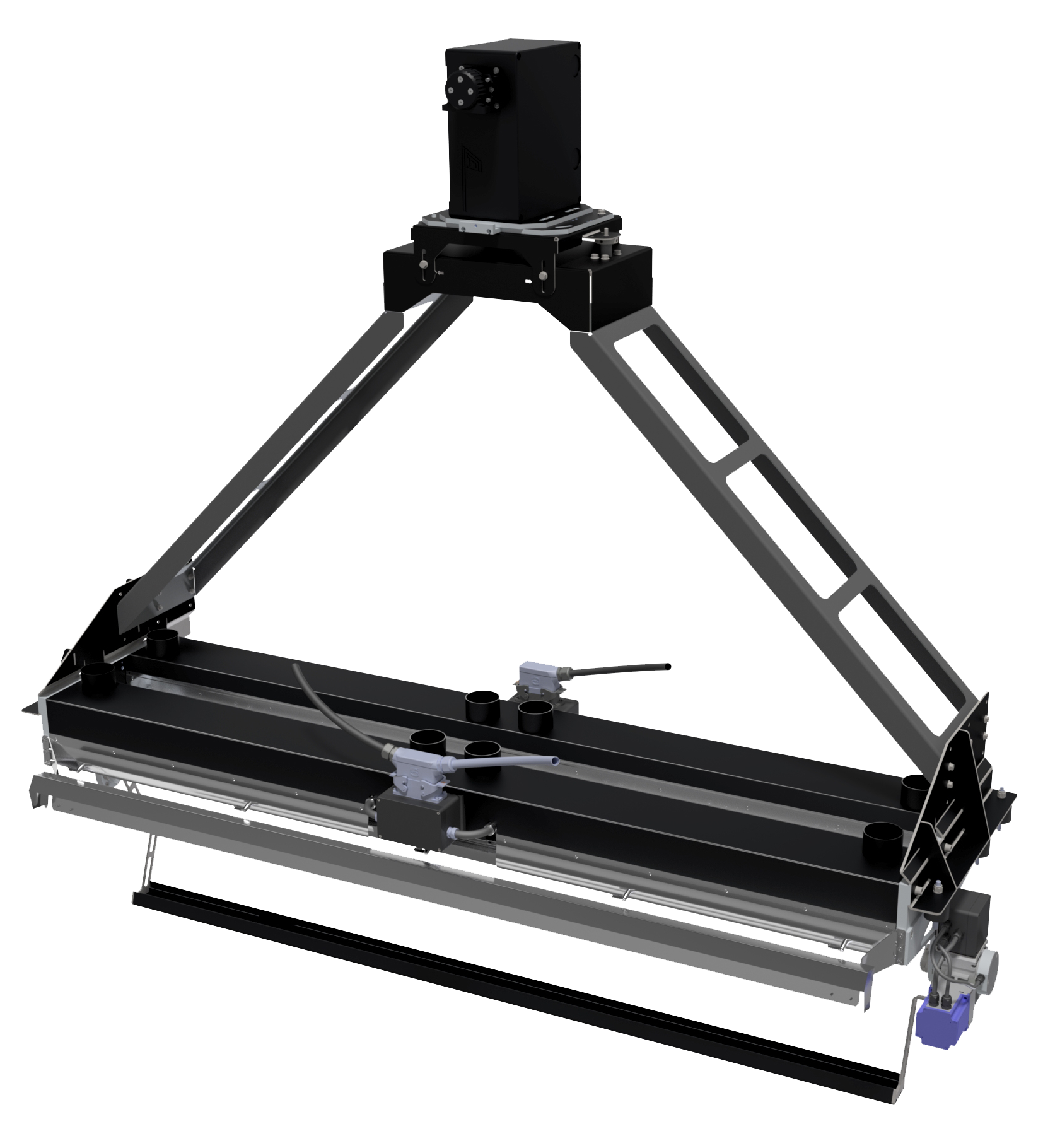

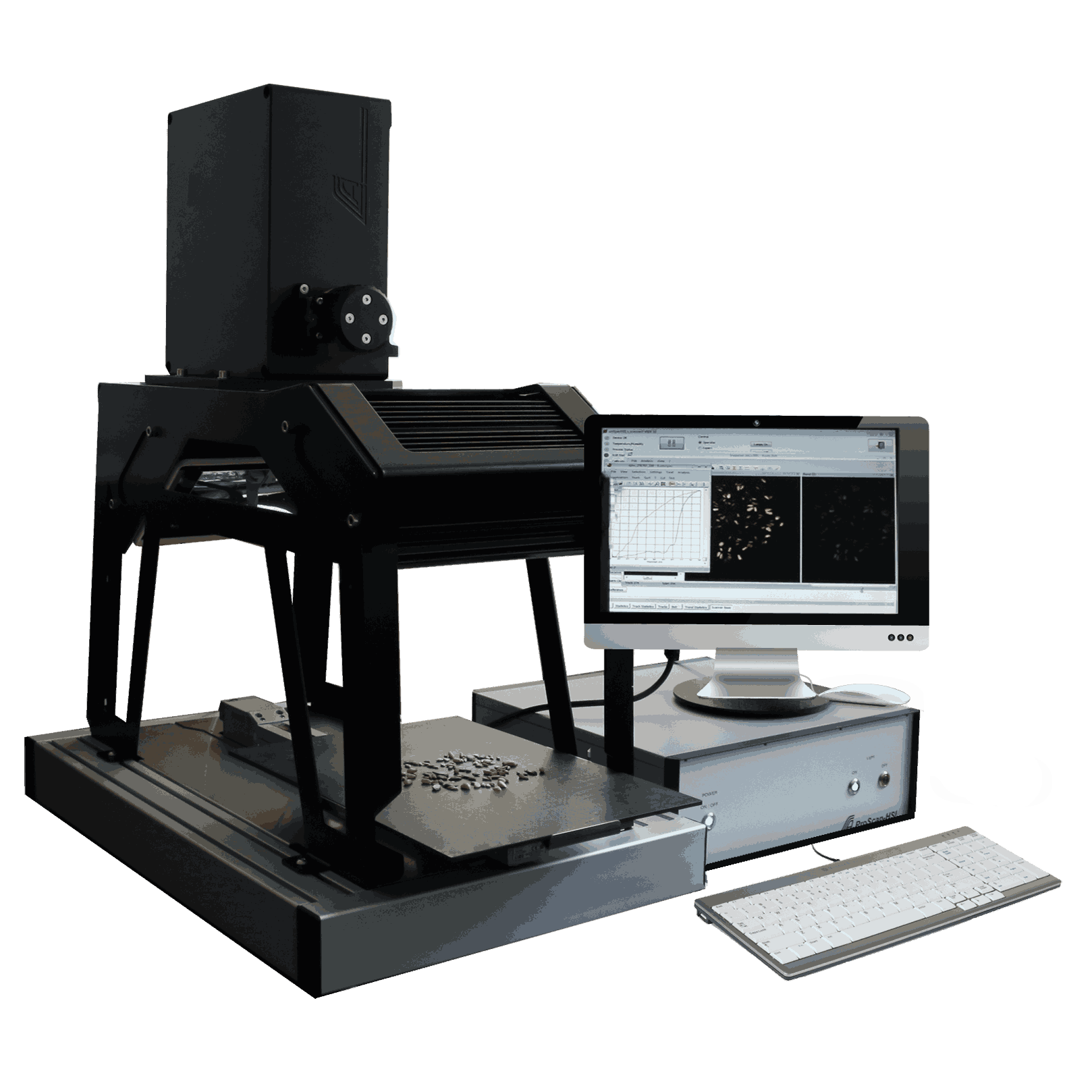

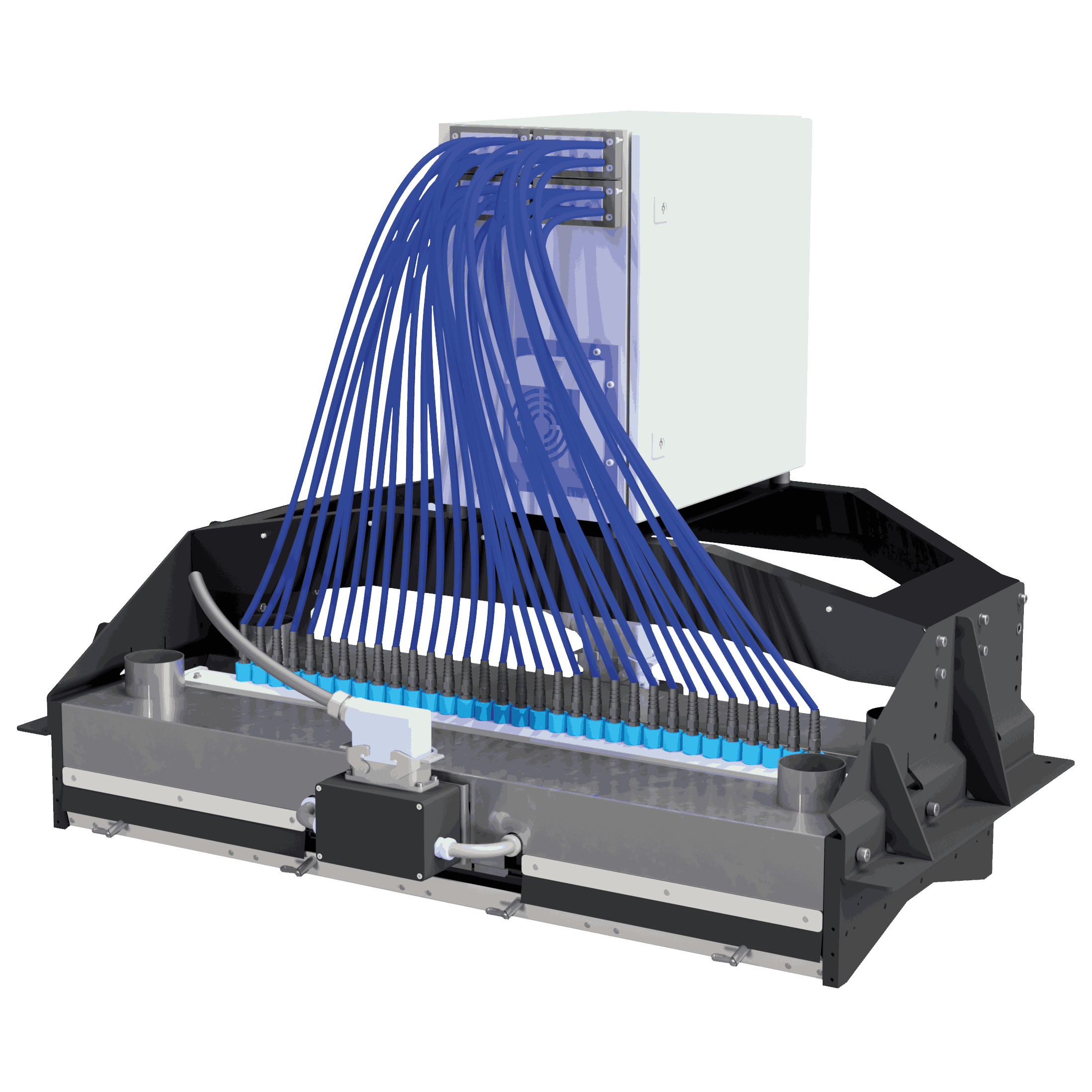

Step 2: Mechanical Integration

A successful integration requires precision alignment and stable mounting:

- Mounting Bridges: Ensure the hyperspectral camera is positioned correctly relative to the conveyor belt and illumination source.

- Illumination Systems: High-quality LED or halogen light sources provide uniform lighting for accurate spectral analysis.

- Calibration Units: Manual or automatic calibration ensures consistent and accurate spectral readings.

Optional integration of RGB line scan cameras can improve spatial detection and complement hyperspectral data for higher sorting accuracy.

Step 3: Software Integration

Hyperspectral cameras generate massive data streams that require real-time processing and analysis. Machine builders typically integrate the camera software with:

- Industrial PCs or embedded IPCs

- PLC or plant control systems via Ethernet

- Valve or actuator control for blow-off or sorting mechanisms

Modern hyperspectral camera software offers:

- Visualization of spectra

- Single and multi-level analysis models

- Pre-built sorting algorithms for plastics, metals, and textiles

- Adaptability for new materials or custom workflows

This integration allows operators to control sorting machines efficiently and make data-driven adjustments in real-time.

Step 4: Electrical & Network Integration

Machine builders must ensure seamless power and data connectivity:

- Use industrial-grade power supplies for camera stability

- Gigabit Ethernet for high-speed data transmission

- Proper cable management and shielding to reduce electrical noise

This ensures high-speed, continuous operation in 24/7 industrial environments.

Step 5: Testing and Commissioning

Before deployment, testing is critical:

- Material Samples: Test with representative materials to fine-tune the camera and software settings

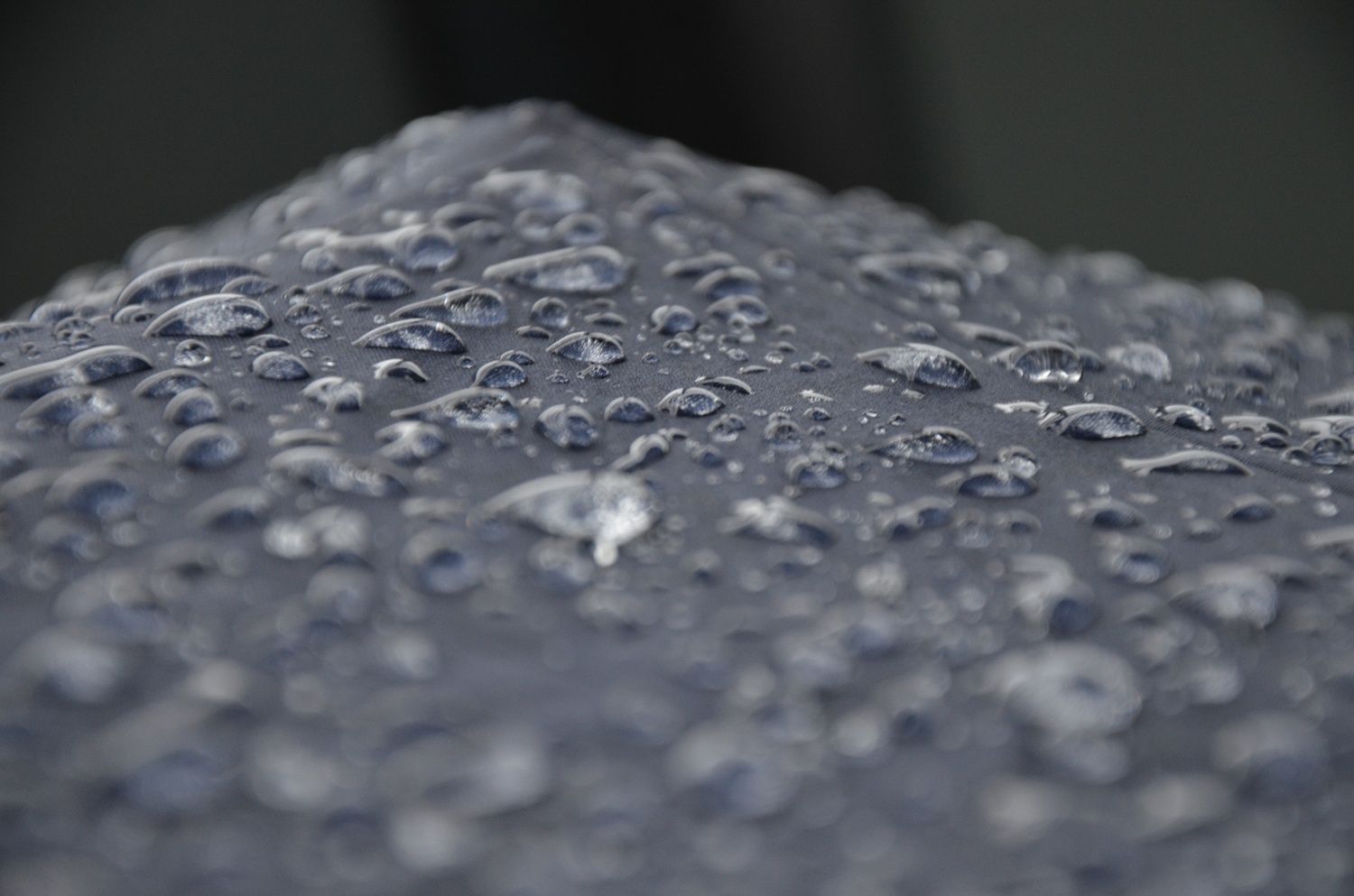

- Environmental Testing: Verify performance in dusty, humid, or high-temperature conditions

- Throughput Optimization: Adjust conveyor speed, camera exposure, and processing pipelines for maximum efficiency

Common Challenges and Best Practices

Challenges:

- Dust, dirt, and harsh environments

- Misalignment or vibration affecting image quality

- High data volume causing latency

Best Practices:

- Choose robust, IP-rated camera systems

- Integrate proper illumination and calibration

- Use modular software for easy adaptation

- Perform on-site testing for real-world conditions

Benefits of Integrating Hyperspectral Cameras

- Accurate material identification: plastics, metals, textiles

- Higher sorting throughput with minimal human intervention

- Reduced waste and contamination

- Flexible integration for conveyor systems from 200 mm to 2800 mm

- Data-driven process optimization for industrial plants

Conclusion

Integrating hyperspectral cameras into sorting machines requires careful selection, precise mechanical setup, seamless software integration, and rigorous testing. For machine builders, the result is highly accurate, high-throughput, and reliable sorting machines that improve efficiency and sustainability in recycling and manufacturing applications.

By following these best practices, OEMs and integrators can leverage the power of hyperspectral imaging to deliver superior industrial sorting solutions.

Call to Action:

Ready to integrate hyperspectral cameras into your sorting machines? Request more information about LLA’s KUSTA-System today.

Previous Post

Previous Post