How NIR-SWIR Imaging is Transforming Food Quality Control and Safety

21 May 2025

How NIR-SWIR Imaging is Transforming Food Quality Control and Safety

In a heavily regulated industry like food production, ensuring consistent product quality and safety isn’t just a priority — it’s a necessity. Yet many traditional quality control methods rely on manual sampling and lab testing, which are often slow, expensive, and limited in scope.

That’s why more manufacturers are turning to NIR-SWIR imaging — a cutting-edge technology that allows real-time, non-contact inspection of food products directly on the production line.

What Is NIR-SWIR Imaging?

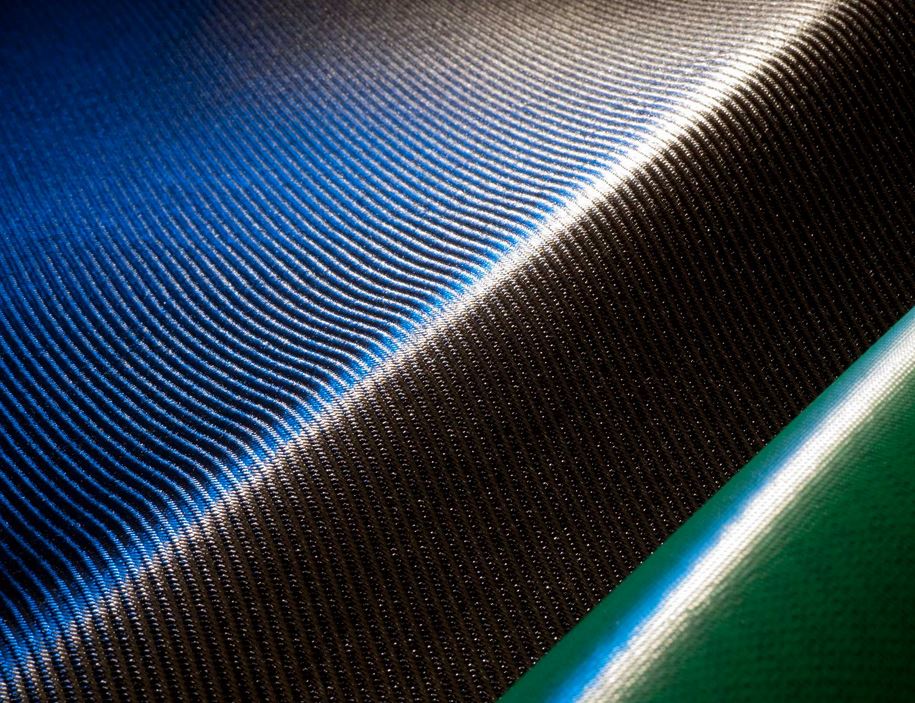

NIR (Near-Infrared) and SWIR (Short-Wave Infrared) imaging work by analyzing the molecular composition of materials using specific wavelengths of light. Unlike traditional sensors that depend on color, shape, or density, SWIR imaging reveals what a product is made of — and that opens up a world of possibilities for quality control.

Key Benefits in Food Production

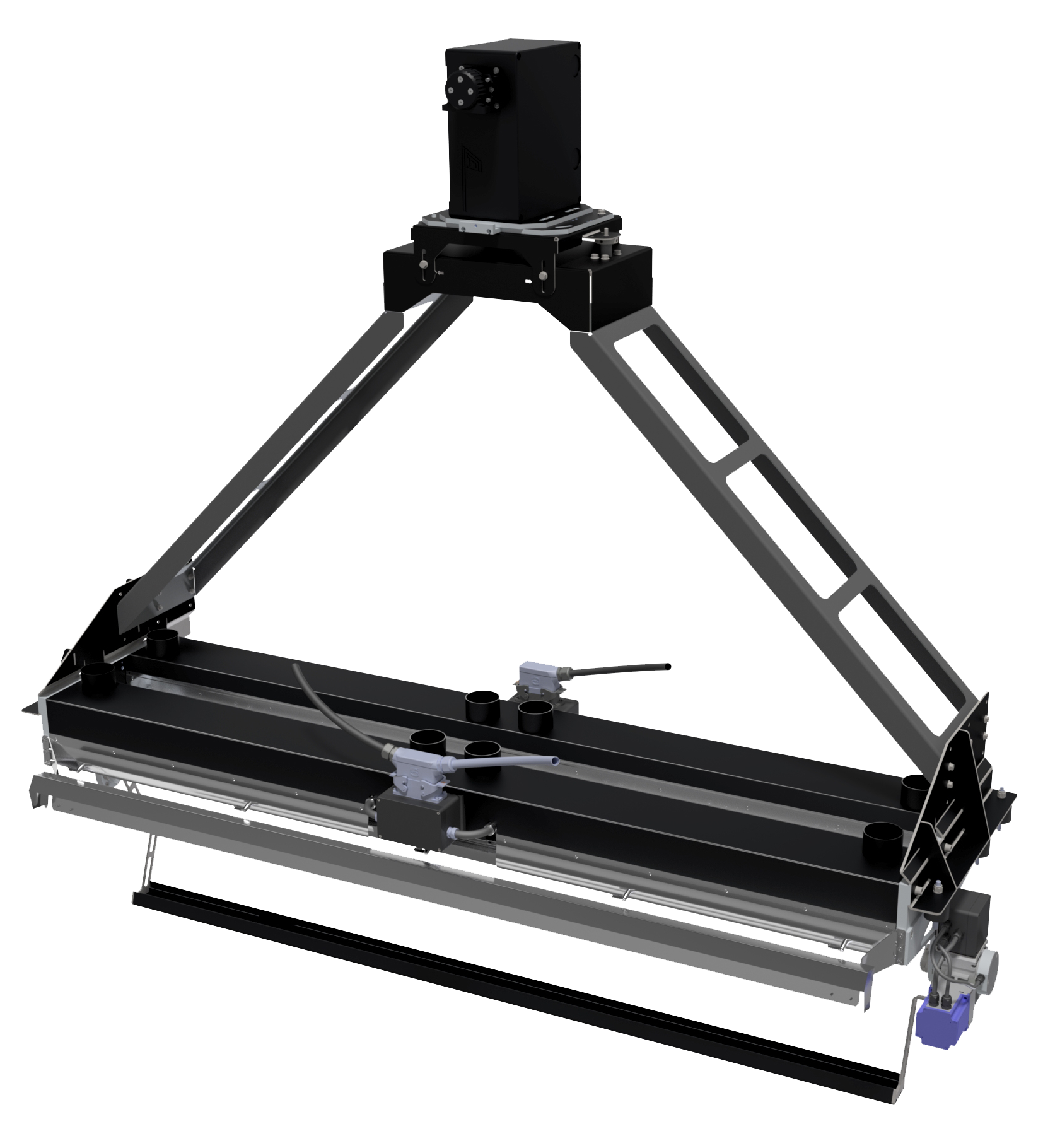

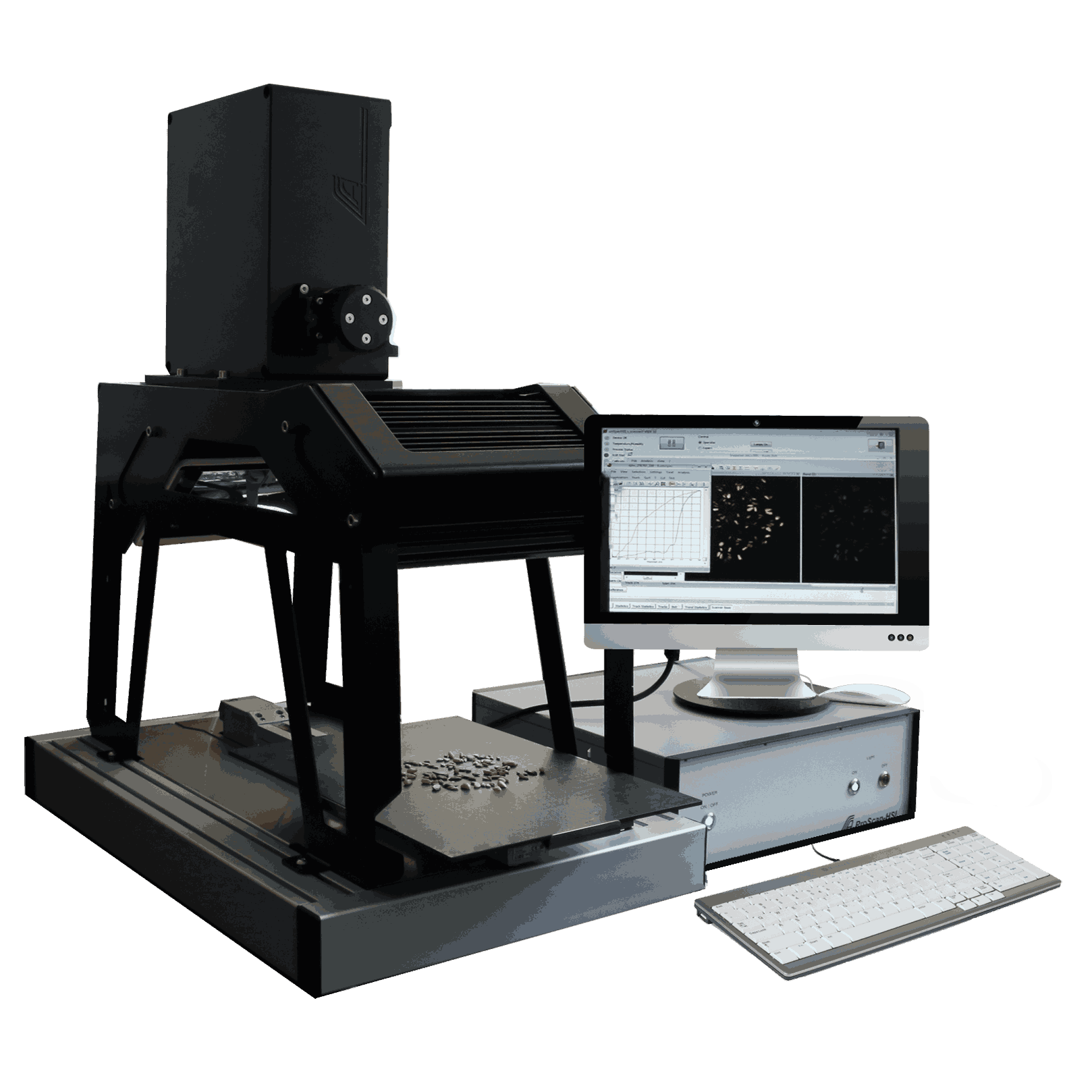

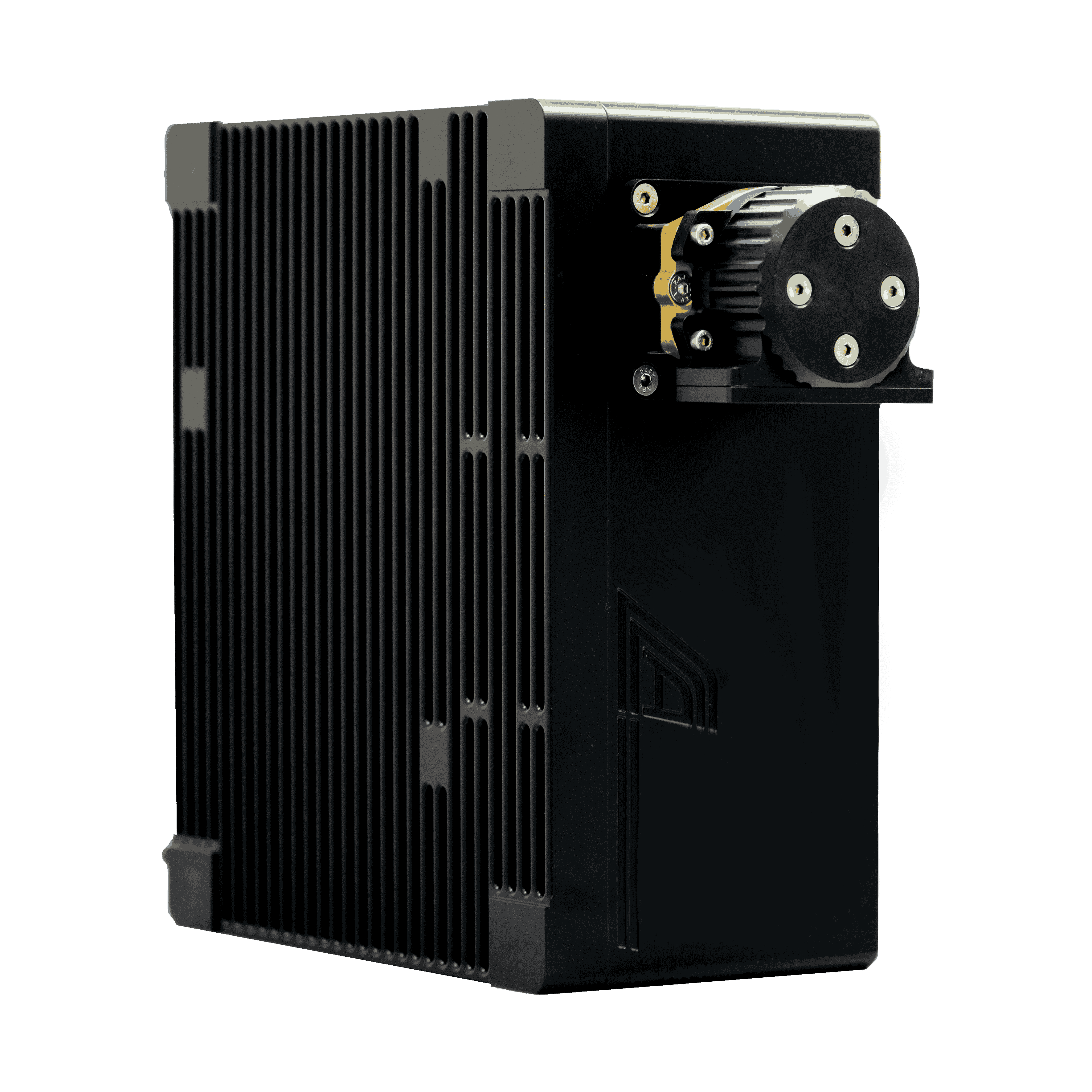

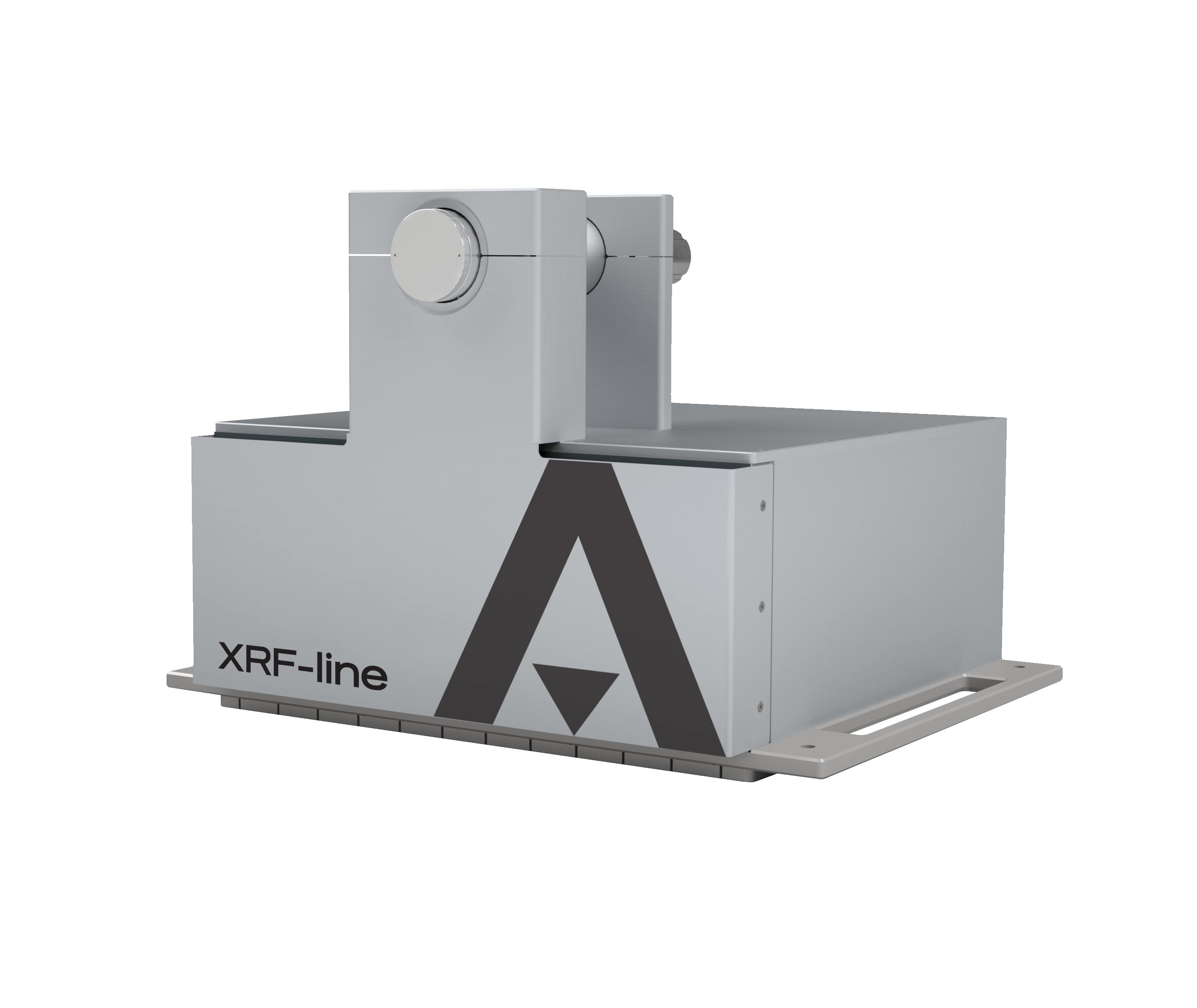

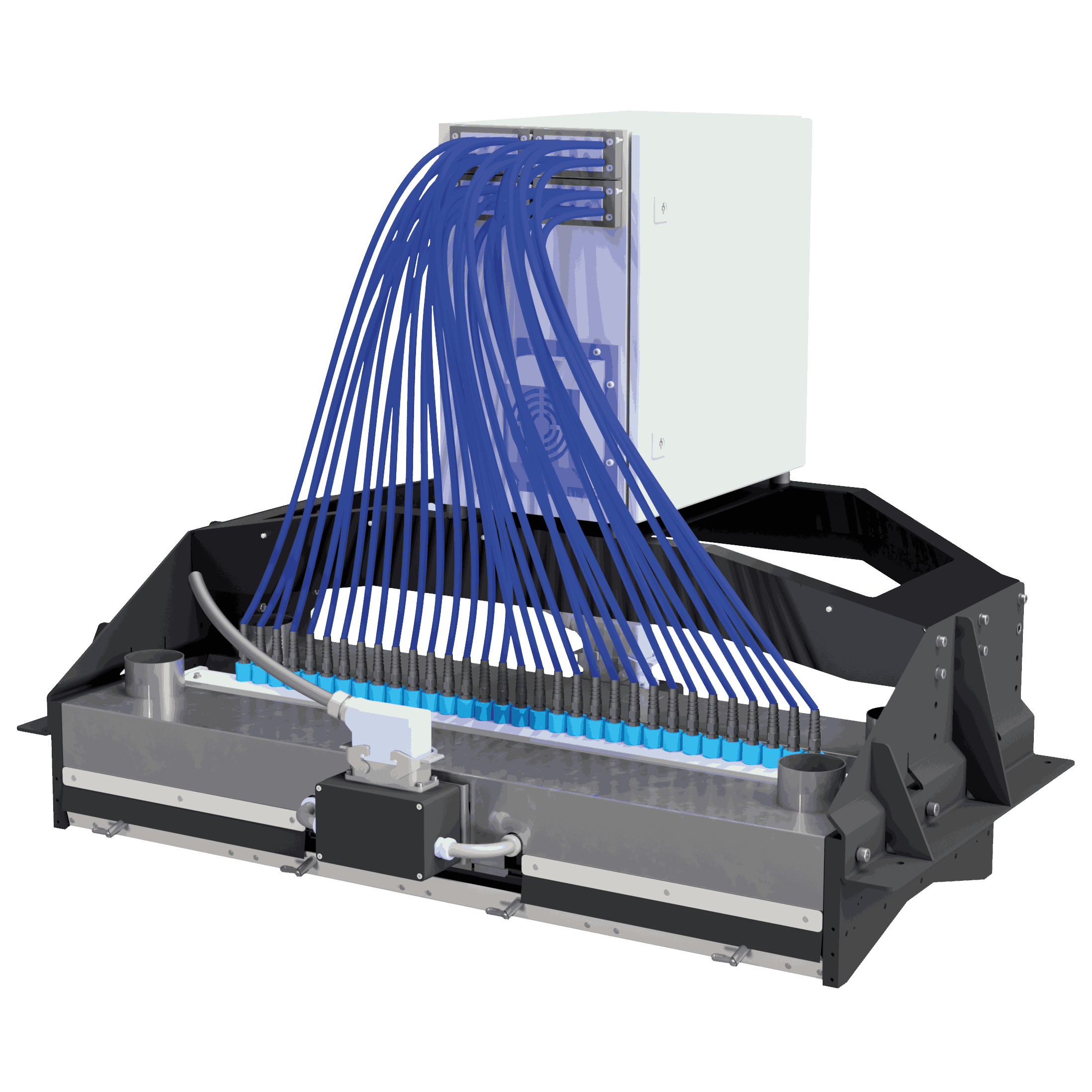

NIR-SWIR imaging systems, such as those developed by LLA Instruments, are already making a measurable impact across the food industry.

Applications include:

✅ Foreign Object Detection

Identify contaminants like plastic, rubber, glass, stones, and bone fragments — even if they’re embedded inside the product.

✅ Nutrient and Composition Analysis

Measure key nutritional components such as fat, moisture, or sugar content for real-time product consistency.

✅ Process Automation and Optimization

Automatically monitor and adjust processing conditions to improve yield, reduce waste, and cut energy costs.

✅ Freshness and Ripeness Checks

Evaluate the quality of fresh fruits, vegetables, or meats without destroying the product.

Why It Matters

With increasing demand for safer, cleaner, and more transparent food supply chains, the ability to inspect every product in real-time offers a major competitive edge. SWIR-based hyperspectral imaging not only meets regulatory compliance but also builds consumer trust by ensuring higher quality and fewer recalls.

Trusted by Industry Experts

LLA Instruments and other industry leaders have been pioneering the use of hyperspectral imaging in industrial environments for years. Their technologies are designed for rugged, high-speed operations — making them ideal for food sorting, grading, and safety inspection.

Previous Post

Previous Post