Home / Applications / Coatings & Lacquers

Coatings & Lacquers

Functional coatings / thin films

Functional coatings and surfaces enhance materials, giving them improved or novel properties, develop new materials for resource-saving industrial use, and increase the durability of products.

The monitoring or characterisation of functional coatings play a pivotal role in ensuring cost-effective and resource-saving manufacturing processes. Our NIR imaging spectrometers make possible new, inline-capable, and automatable processes. They allow for materials testing, process monitoring, and quality assurance in the UV, VIS and NIR spectral range.

If your application is not listed in the following examples, please don’t hesitate to contact us! We will develop a suitable solution that matches your requirements.

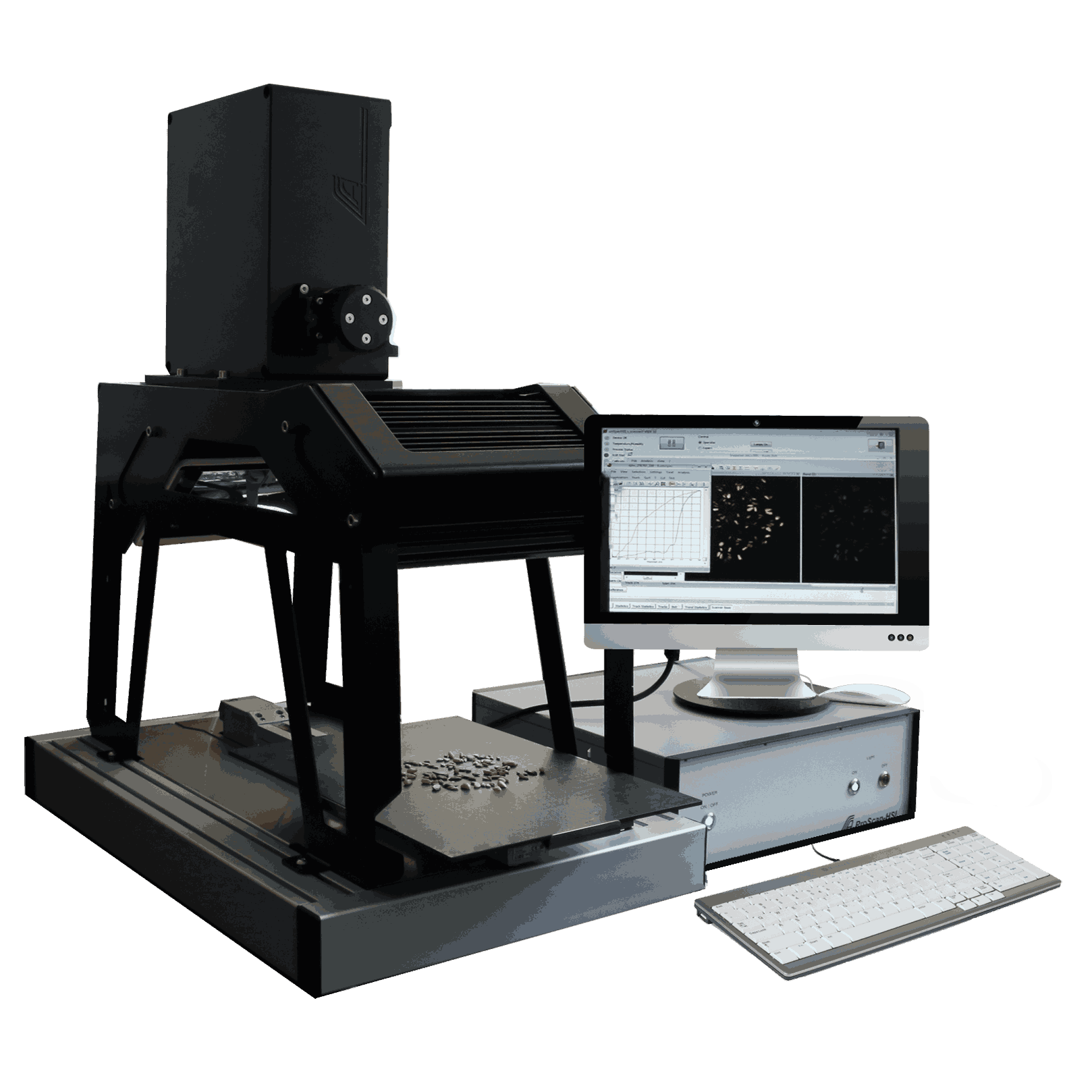

Optical coatings

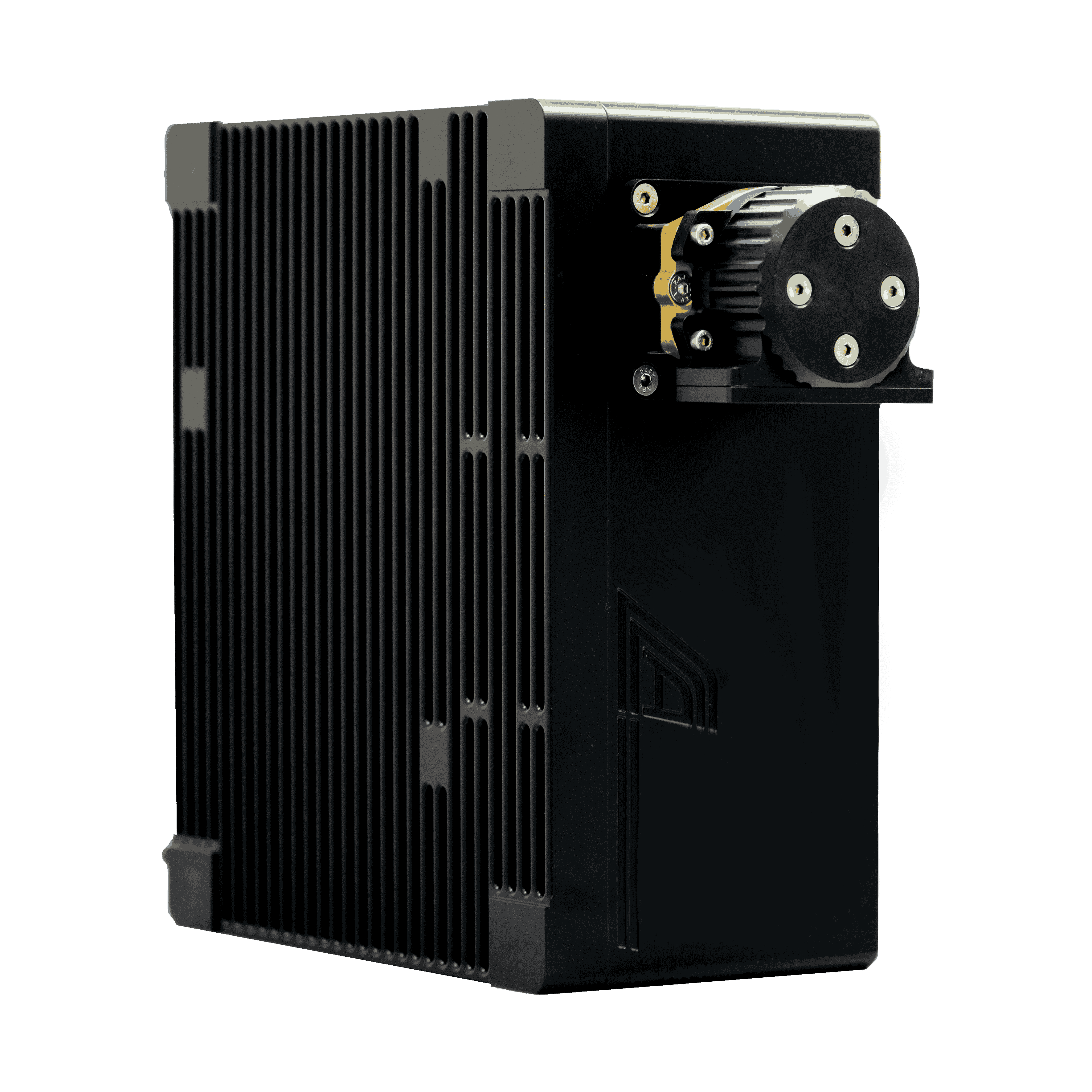

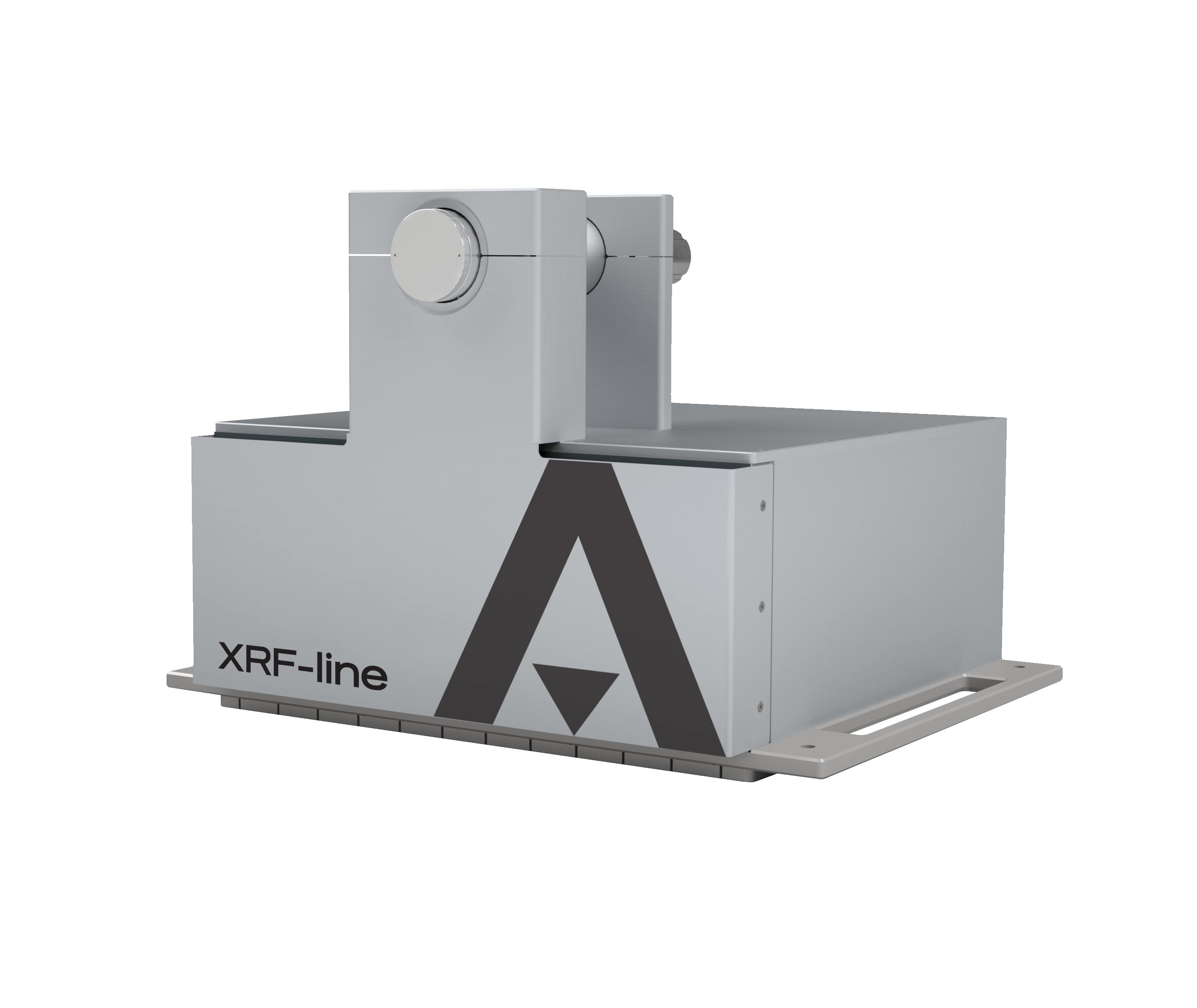

WE RECOMMEND: The KUSTA 1.9 hyperspectral camera or the NIR Spectrometer KUSTA-MPL 1.9

These devices measure spectral characteristics of the levels of reflectance/transmittance of optical components with spatial resolution in the wavelength range of 350–2200 nm. Typical use cases include the analysis of metals with high absorption/reflectance and dielectric materials with high transparency.

Additionally, a typical application is the automated full-area material inspection of eyeglasses or filter glasses with dielectric coatings in the UV, VIS and NIR spectral range, directly after the vapor deposition process. For these processes, we recommend our NIR hyperspectral cameras – multiplexed NIR Spectrometer.

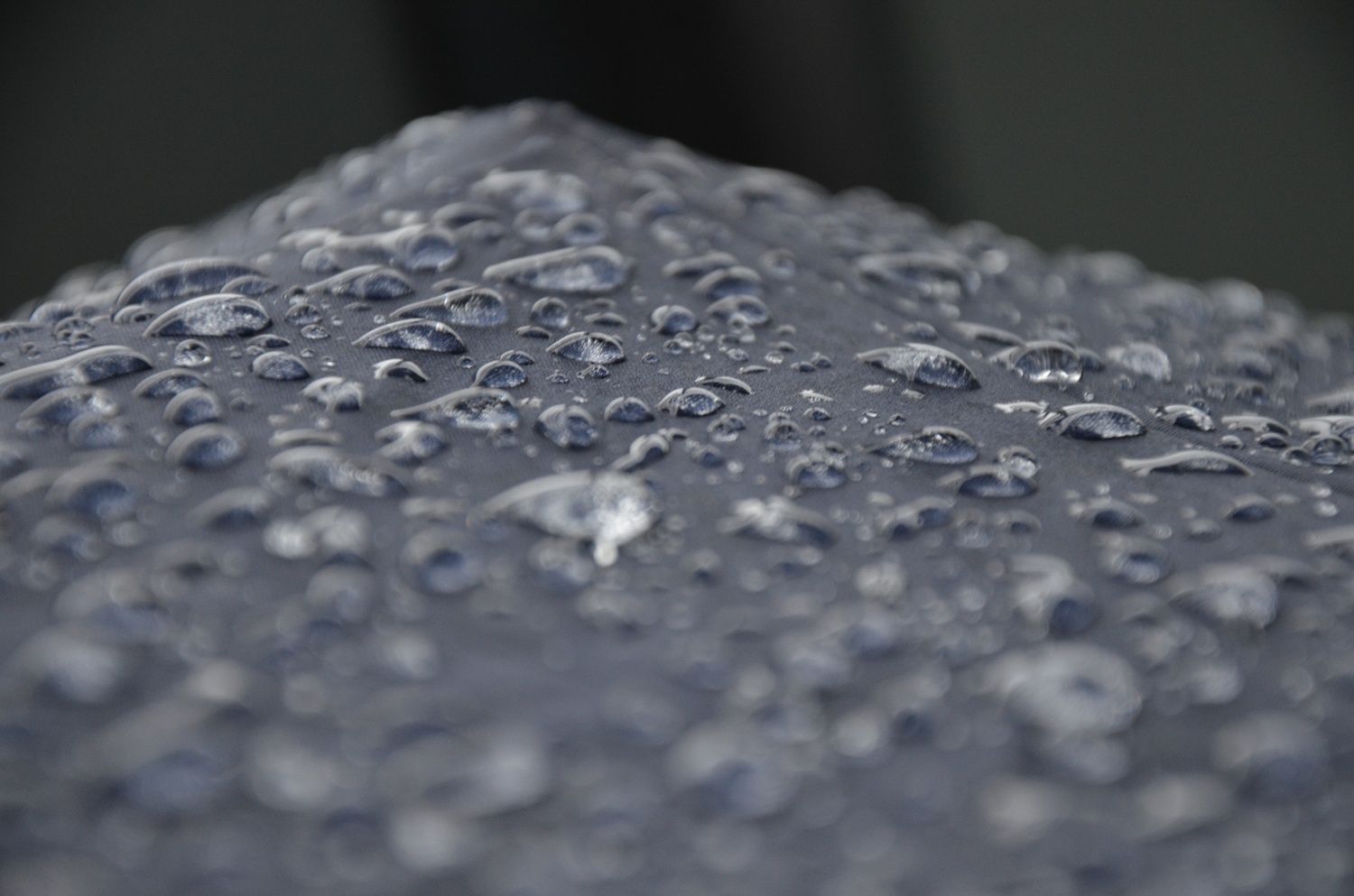

Surface finishing

WE RECOMMEND: The KUSTA 1.9 hyperspectral camera or the NIR Spectrometer KUSTA-MPL 1.9

In a quality assurance context, it is often not sufficient to evaluate the optical properties in the visible spectral range following the manufacturing process. For this reason, NIR imaging spectrometers are used to efficiently monitor the chemical homogeneity of paint coatings.

Among other things, this allows for the detection of the spatial distribution of fillers, coating thickness, and coating damage. For these applications, we recommend our NIR hyperspectral cameras as well as the multiplexed NIR spectrometer.

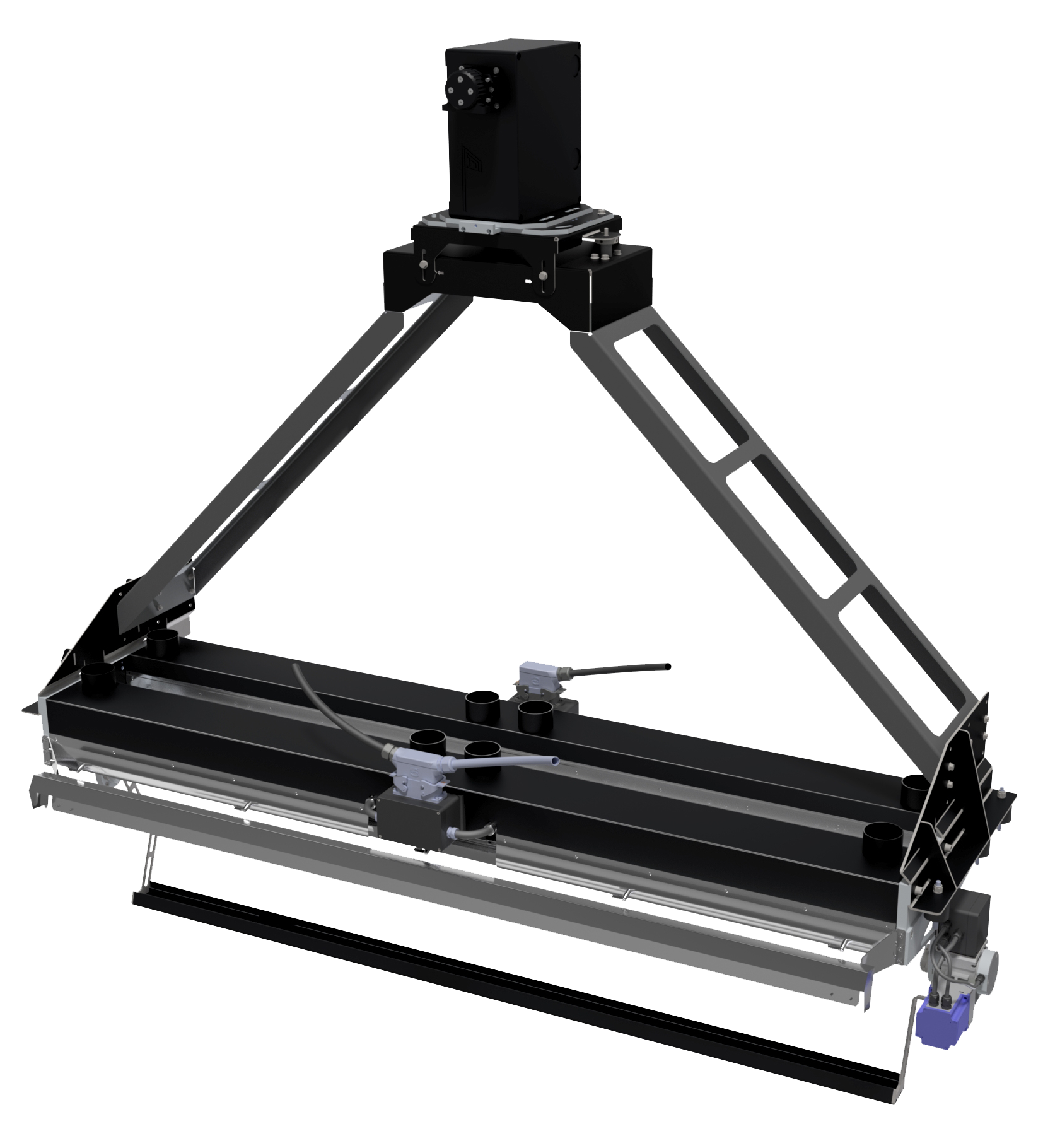

Application of adhesives for material composites

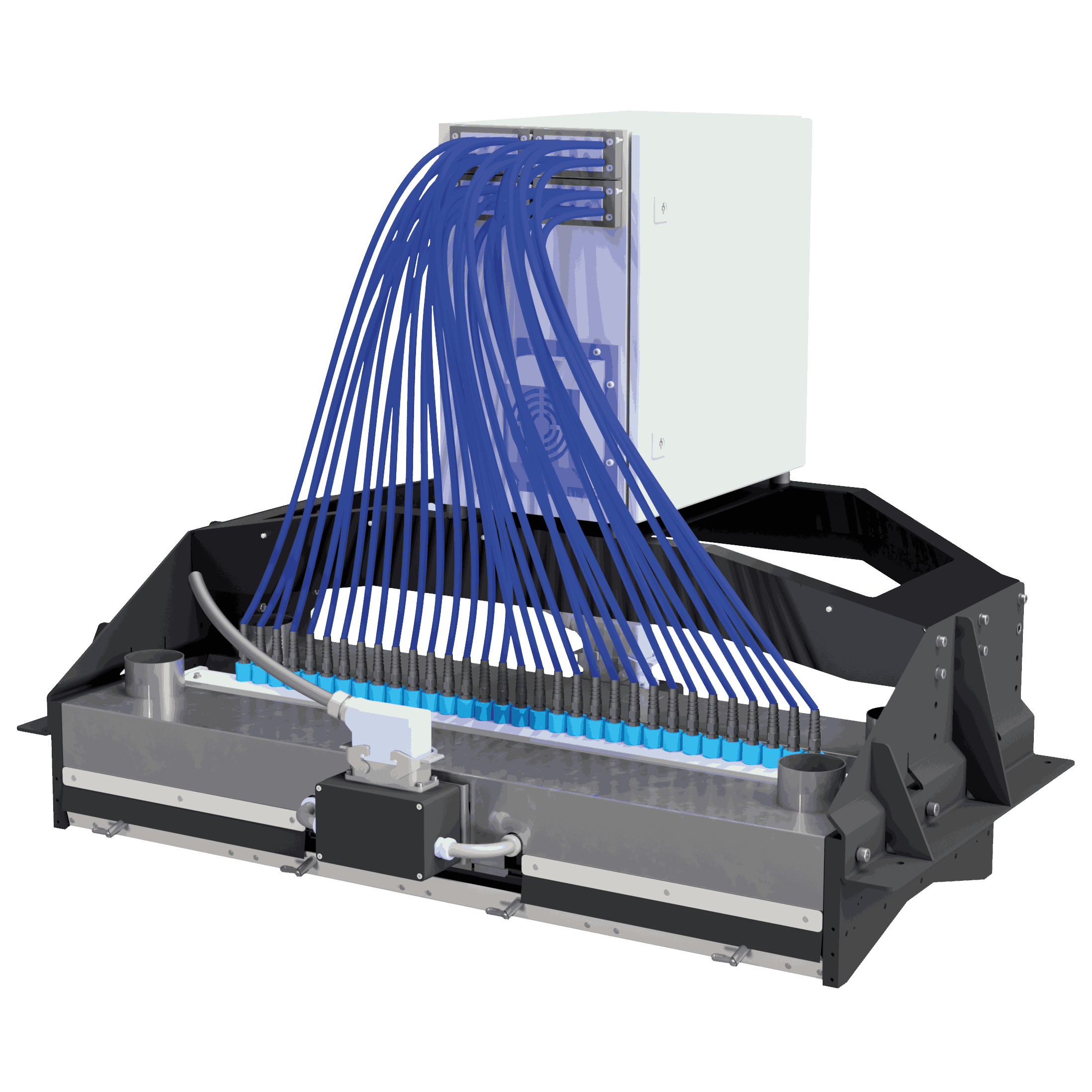

WE RECOMMEND: The NIR spectrometer KUSTA 1.9

Your business can reduce costs and enhance its competitiveness by improving the efficiency of the use of materials. Insufficient adhesive application or incorrect bonding, for example, is something that should be prevented.

Our imaging NIR hyperspectral camera KUSTA 1.9 can take care of this additional quality assurance step. As an inline-capable measuring system, it checks the application and thickness of adhesive layers on component surfaces.

UV curing varnish coatings

WE RECOMMEND: The NIR spectrometer KUSTA 1.9

When curing or drying UV-curing colorants and coatings, unnoticed changes in sensitive process conditions can lead to significant quality defects. Inline monitoring of turnover can detect such changes at an early stage and then initiate all necessary measures to control relevant process parameters. Using our multiplexed NIR spectrometer, you can measure layer thicknesses of a few micrometres and get a fast result for the PLS.

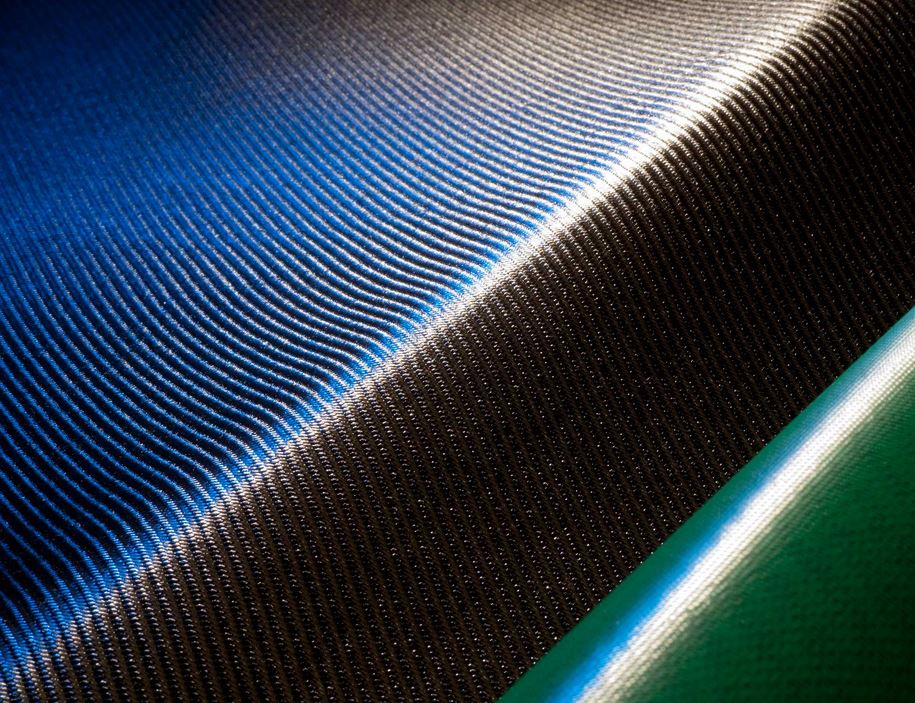

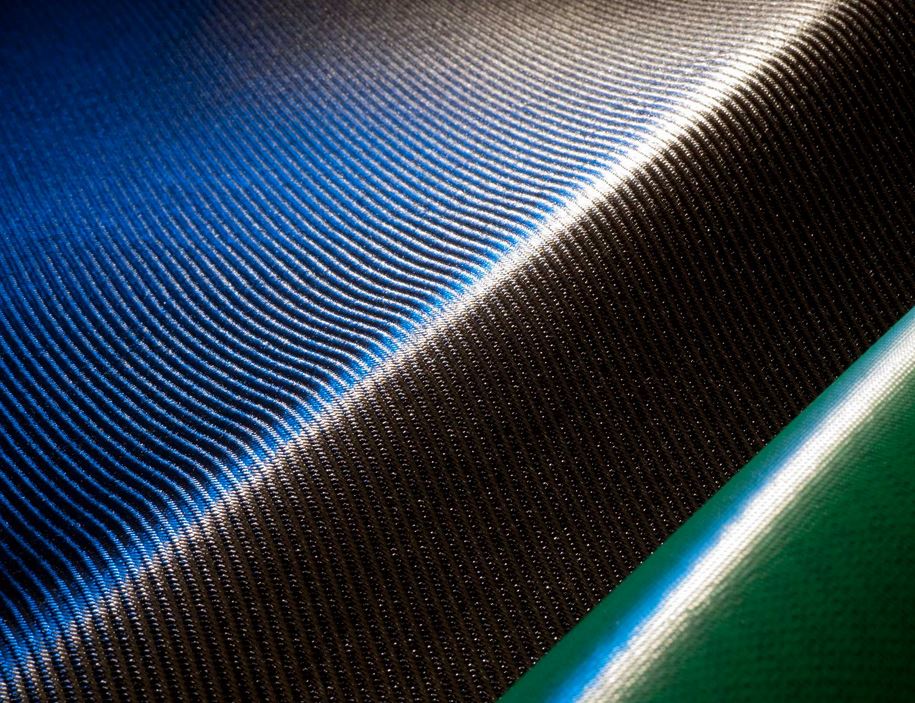

Industrial textiles

WE RECOMMEND: The NIR spectrometer KUSTA 1.9

The following material properties can be monitored using our inline-capable measuring systems:

- chemical composition (fibres, plastics, textiles, adhesives, etc.),

- the quality of surface pre-treatment, moisture of textiles, quality of adhesive application and its residues as well as lamination defects.

We at LLA Instruments have compared our NIR measurement techniques for analysing various surfaces in cooperation with IOM Leipzig.

Prepregs

WE RECOMMEND: The NIR spectrometer KUSTA 1.9

In quality assurance of prepregs, process control during production is very important. This can be carried out efficiently using our inline-capable measuring systems. They help you with real-time monitoring of, for example, resin and fabric composition, solvent content, viscosity and degree of hardness of prepregs, and, if necessary, enables you to adjust the process parameters.: